Technical Data

Original Instructions

Compact 5000 I/O and Specialty Modules Specifications

Catalog Numbers

The Compact 5000™ I/O architecture provides a wide range of input and output modules to span many applications, from high-speed digital

to process control. The architecture uses Producer/Consumer technology that allows input information and output status to be shared

among multiple Logix 5000® controllers.

Compact 5000 I/O modules are used as local I/O modules in CompactLogix™ 5380 and Compact GuardLogix® 5380 controller systems. The

modules are also used as remote I/O modules with CompactLogix 5380, Compact GuardLogix 5380 controllers, and some other Logix 5000

controllers. You use the Studio 5000 Logix Designer® application to configure the modules.

The I/O modules require a removable terminal block (RTB) to connect field-side wiring. RTBs are not included with the I/O modules. You must

order RTBs separately.

Digital I/O Modules

5069-IA16, 5069-IB16, 5069-IB16F, 5069-IB16K, 5069-IB6F-3W,

5069-OA16, 5069-OB8, 5069-OB16, 5069-OB16F, 5069-OB16K,

5069-OW4I, 5069-OW16, 5069-OX4I

Analog I/O Modules

5069-IF4IH, 5069-IF8, 5069-IY4, 5069-IY4K, 5069-OF4, 5069-OF4K,

5069-OF4IH, 5069-OF8

Safety I/O Modules 5069-IB8S, 5069-IB8SK, 5069-OBV8S, 5069-OBV8SK

Specialty Modules

5069-AENTR, 5069-AENTRK, 5069-AEN2TR, 5069-ARM, 5069-FPD,

5069-HSC2XOB4, 5069-SERIAL

Topic Page

Summary of Changes 2

Power the Compact 5000 I/O Modules 2

Minimum Space Requirements 2

Digital I/O Modules 5

Analog I/O Modules 17

Safety I/O Modules 31

Specialty Modules 39

Additional Resources 51

2 Rockwell Automation Publication 5069-TD001O-EN-P - May 2024

Compact 5000 I/O and Specialty Modules Specifications Technical Data

Summary of Changes

This publication contains the following new or updated information. This list includes substantive updates only and is not intended to reflect

all changes. Change bars identify changes throughout the manual.

Power the Compact 5000 I/O Modules

There are different types of power that are used with Compact 5000 I/O modules.

For more information on MOD power, SA power, and LA power, see the user manuals in Additional Resources on page 51

.

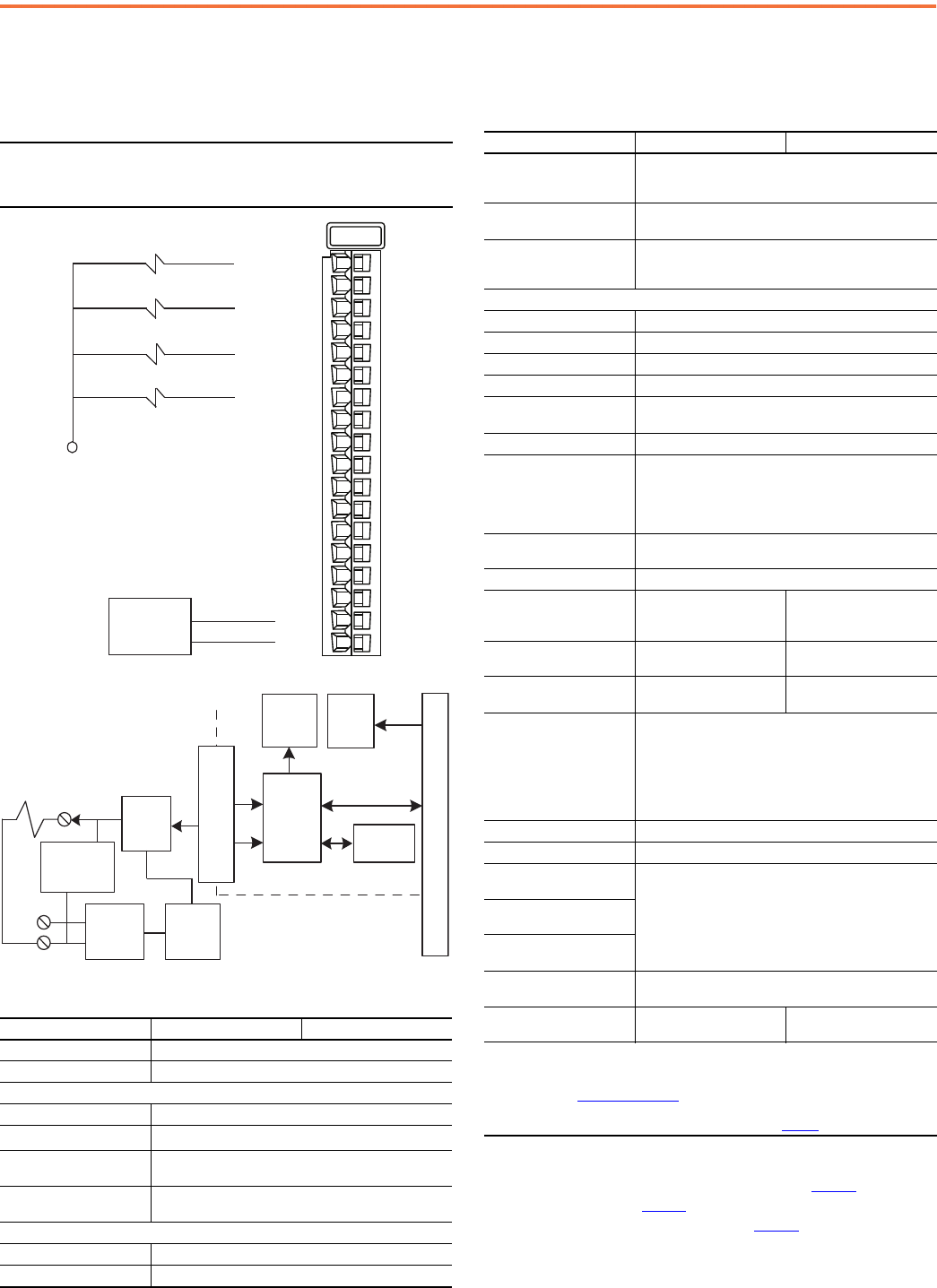

Minimum Space Requirements

There are minimum space requirements that are based on whether Compact 5000 I/O modules are installed in a CompactLogix™ 5380,

Compact GuardLogix® 5380, CompactLogix 5480 controller system or in a Compact 5000 I/O EtherNet/IP™ adapter system.

Topic Pages

Updated the c-UL-us certification for the digital and analog modules 6, 18

Added the HART I/O modules, 5069-IF4IH and 5069-OF4IH Throughout

Power Type Description

Related Specifications

Name Description

Module (MOD)

Power

System-side power that is used to operate a local or remote system. Power passes across a

MOD power bus. Modules draw current from the bus and pass the remaining current to the

next module.

MOD power

Level of MOD power current that the module

draws from the MOD power bus

MOD power

(passthrough)

Maximum level of MOD power current that the

module can pass to the next module.

Sensor

Actuator (SA)

Power

Field-side power that some modules use to power field-side devices. Power passes across

an SA power bus. Some modules draw current from the bus and pass the remaining current

to the next module. Other modules do not draw current from the bus but do pass the

current to the next module.

You use 5069-FPD field potential distributors to establish new SA power buses in a system.

IMPORTANT:

• If the system includes DC type modules and AC type modules, you must use a field

potential distributor to install them on separate SA power buses.

• You cannot install AC type modules directly next to a Compact GuardLogix 5380

controller. You must first install a field potential distributor.

SA power

Level of SA power current that the module

draws from the SA power bus

SA power

(passthrough)

Maximum level of SA power current that the

module can pass to the next module.

Local Actuator

(LA) Power

Field-side power that some Compact 5000 I/O modules use instead of SA power. Modules

that use LA power do not use SA power. They only pass SA power to the next I/O module in

the system.

You must install modules that use LA power on an SA power bus with the same SA power

type. For example, the 5069-OB8 module uses LA power but is still a DC-type module, so you

must install it on a DC SA power bus.

LA power

Maximum level of LA power current that you

can apply to the module, by channel, group,

or module.

IMPORTANT If Compact 5000 I/O modules are installed next to a CompactLogix 5380 or Compact GuardLogix 5380, or CompactLogix

5480 controller, you must mount the system horizontally.

You can mount CompactLogix 5480 controllers in any orientation if there are no Compact 5000 I/O modules installed next

to the controller.

3 Rockwell Automation Publication 5069-TD001O-EN-P - May 2024

Compact 5000 I/O and Specialty Modules Specifications Technical Data

CompactLogix 5380 or Compact GuardLogix 5380

System Minimum Space Requirements

The minimum distance between all sides of the CompactLogix 5380

system or Compact GuardLogix 5380 system and enclosure walls,

wireways, and adjacent equipment varies based on the current

operating temperature.

For more information on how to install a CompactLogix 5380

controller system, see the CompactLogix 5380 Controllers

Installation Instructions, publication 5069-IN013

.

For more information on how to install a Compact GuardLogix 5380

controller system, see the Compact GuardLogix 5380 SIL 2

Controllers Installation Instructions, publication 5069-IN014

.

CompactLogix 5480 System Minimum Space

Requirements

The minimum distance for a system that includes only a

CompactLogix 5480 controller is as follows:

• 25.00 mm (0.98 in.) between the sides of the controller

and the cabinet

• 25.00 mm (0.98 in.) between the front of the controller

and the cabinet

• 50.00 mm (1.96 in.) between the top and bottom of the

controller and the cabinet

We recommend that you install the controller near the bottom of the

enclosure, where the ambient temperature is lower.

For more information on how to install a CompactLogix 5480

controller system, see the CompactLogix 5480 Controllers

Installation Instructions, publication 5069-IN019

.

Controllers

Minimum Space at

50 °C (122 °F) 55 °C (131 °F) 60 °C (140 °F)

CompactLogix 5380

Standard and Process

Controllers

50.8 mm

(2.00 in)

50.80 mm

(2.00 in)

101.60 mm

(4.00 in)

Compact GuardLogix 5380

SIL 2 Controllers

Series A catalog numbers

50.8 mm

(2.00 in)

101.6 mm

(4.00 in)

152.4 mm

(6.00 in)

Series B catalog numbers

50.8 mm

(2.00 in)

50.8 mm

(2.00 in)

101.6 mm

(4.00 in)

Compact GuardLogix 5380

SIL 3 Controllers

50.8 mm

(2.00 in)

50.8 mm

(2.00 in)

101.6 mm

(4.00 in)

Top

Bottom

Side

Side

CompactLogix 5380 or

Compact GuardLogix 5380

Controller

Compact 5000™ I/O

End Cap

Compact 5000 I/O

™

Top

Bottom

Side

Side

End cap

Cabinet

Front

Side View

4 Rockwell Automation Publication 5069-TD001O-EN-P - May 2024

Compact 5000 I/O and Specialty Modules Specifications Technical Data

Adapter Minimum Space Requirements

The minimum distance on all sides of the adapter system is as follows:

• 25.40 mm (1.00 in) - If the system uses only Compact 5000 I/O standard modules.

• 50.80 mm (2.00 in) - If the system uses at least one Compact 5000 I/O safety module.

For more information on how to install a Compact 5000 I/O EtherNet/IP adapter system, see the Compact 5000 I/O

EtherNet/IP Adapters Installation Instructions, publication 5069-IN003

.

Horizontal Mounting

Vertical Mounting

Only the 5069-AENTR adapter supports vertical mounting.

Top

Bottom

SideSide

Compact 5000 I/O

EtherNet/IP Adapter

Compact 5000 I/O

End cap

Compact 5000 I/O

Top

Bottom

Side

Side

Compact 5000 I/O

EtherNet/IP Adapter

Compact 5000 I/O

End cap

Compact 5000 I/O

Rockwell Automation Publication 5069-TD001O-EN-P - May 2024 5

Compact 5000 I/O Modules and EtherNet/IP Adapters

Digital I/O Modules

For information that applies to all of the digital I/O modules, see these tables.

• Wiring and Installation Specifications - Digital I/O Modules

• Certifications - Digital I/O Modules

• Environmental Specifications - Digital I/O Modules

The following digital I/O modules are available.

I/O Type Cat. No. Description Page

AC digital input 5069-IA16 16-point 120/240V AC input module 7

DC digital input

5069-IB16 16-point sinking input module

85069-IB16K 16-point, conformal-coated sinking input module

5069-IB16F 16-point, sinking fast input module

5069-IB6F-3W 3-wire, sinking fast input module 9

AC digital output 5069-OA16 16-point 120/240V AC output module 10

DC digital output

5069-OB8 8-point 24V DC output module 11

5069-OB16 16-point, sourcing, high-current output module

125069-OB16K 16-point, conformal-coated sourcing output module

5069-OB16F 16-point, sourcing fast output module

Relay output

5069-OW4I 4-point, isolated, normally-open relay output module 13

5069-OW16 16-point, normally-open relay output module 14

5069-OX4I 4-point, isolated, normally-open/normally-closed relay output module 16

Wiring and Installation Specifications - Digital I/O Modules

Attribute

5069-IA16, 5069-IB16, 5069-IB16K, 5069-IB16F, 5069-IB6F-3W, 5069-OA16,

5069-OB8, 5069-OB16, 5069-OB16K, 5069-OB16F, 5069-OW4I, 5069-OX4I

5069-OW16

Channel connections

The wiring diagrams show devices that are connected to specific channels. You are not restricted to using only those channels. You can connect devices to any

channel or combination of channels as needed.

SA power device list

Connections to an external power supply that provides SA power via the SA power RTB on one of these devices.

• CompactLogix 5380 controller

• CompactLogix 5480 controller

• 5069-AENTR EtherNet/IP Adapter

• 5069-FPD field potential distributor

Isolate SA power

If you install modules in a system that uses both AC SA power and DC SA power, you must isolate SA power buses by type with a 5069-FPD field potential distributor.

To create separate SA power buses, complete these steps.

1. Install the modules that use one type of SA power, for example DC, to the right of the adapter or controller. This is the first SA power bus.

2. To create a second SA power bus, install the 5069-FPD field module to the right of these modules.

3. Install the modules that use the other type of SA power, for example AC, to the right of the 5069-FPD module.

Slot width 1 1.5

Dimensions (HxWxD) 144.57 x 22 x 105.42 mm (5.69 x 0.87 x 4.15 in.) 144.57 x 36 x 105.42 mm (5.69 x 1.42 x 4.15 in.)

Weight, approx 175 g (0.39 lb) 240 g (0.53 lb.)

DIN rail Compatible zinc-plated chromate-passivated steel DIN rail. You can use the EN50022 - 35 x 7.5 mm (1.38 x 0.30 in.) DIN rail.

Module keying Electronic keying via programming software

RTB

5069-RTB18-SPRING RTB or 5069-RTB18-SCREW RTB, according to your system

NOTE: RTBs do not ship with Compact 5000™ I/O modules, you must order them separately. Order only the RTB type that your system requires.

RTB torque Screw-type RTB only: 0.4 N•m (3.5 lb•in)

RTB keying None

Wire size

0.5…1.5 mm

2

(22…16 AWG) solid or stranded shielded copper wire rated at 105 °C (221 °F) or greater

5069-RTB18-SPRING RTB: 2.9 mm (0.11 in.) max diameter including insulation, single wire connection only.

5069-RTB18-SCREW RTB: 3.5 mm (0.14 in.) max diameter including insulation, single wire connection only.

For the 5069-OW16 module only: Use minimum 18 AWG, 105 °C (221 °F) rated wire for load connections to relay output modules.

Insulation-stripping length

5069-RTB18-SPRING RTB: 10 mm (0.39 in.)

5069-RTB18-SCREW RTB: 12 mm (0.47 in.)

6 Rockwell Automation Publication 5069-TD001O-EN-P - May 2024

Compact 5000 I/O Modules and EtherNet/IP Adapters

Environmental Specifications - Digital I/O Modules

Attribute

5069-IA16,

5069-OA16,

5069-OB8,

5069-OW16

5069-OW4I,

5069-OX4I

5069-IB16, 5069-IB16K,

5069-IB16F, 5069-IB6F-3W,

5069-OB16, 5069-OB16K,

5069-OB16F

Temperature, operating

IEC 60068-2-1

(Test Ad, Operating Cold)

IEC 60068-2-2

(Test Bd, Operating Dry Heat)

IEC 60068-2-14

(Test Nb, Operating Thermal

Shock)

0…60 °C (32…140 °F)

Temperature, surrounding

air, max

60 °C (140 °F)

Temperature,

nonoperating

IEC 60068-2-1 (Test Ab,

Unpackaged Nonoperating Cold)

IEC 60068-2-2 (Test Bb,

Unpackaged Nonoperating Dry

Heat)

IEC 60068-2-14 (Test Na,

Unpackaged Nonoperating

Thermal Shock)

-40…+85 °C (-40…+185 °F)

Relative humidity

IEC 60068-2-30 (Test Db,

Unpackaged Damp Heat)

5…95% noncondensing

Vibration

IEC 60068-2-6 (Test Fc,

Operating)

5 g @ 10…500 Hz

Shock, operating

IEC 60068-2-27 (Test Ea,

Unpackaged Shock)

30 g

Shock, nonoperating

IEC 60068-2-27 (Test Ea,

Unpackaged Shock)

50 g

Emissions IEC 61000-6-4

ESD immunity

IEC 61000-4-2

6 kV contact discharges

8 kV air discharges

Radiated RF immunity

IEC 61000-4-3

10V/m with 1 kHz sine wave 80% AM from 80…6000 MHz

EFT/B immunity

IEC 61000-4-4

±4 kV @ 5 kHz on power ports

±4 kV @ 5 kHz on signal ports

±4 kV @ 5 kHz on power ports

±3 kV @ 5 kHz on input ports

Surge transient immunity

IEC 61000-4-5

±1 kV line-line (DM) and ±2 kV line-earth (CM) on power ports

±1 kV line-line (DM) and ±2 kV line-earth (CM) on signal ports

Conducted RF immunity

IEC 61000-4-6

10V rms with 1 kHz sine wave 80% AM from 150 kHz…80 MHz

Voltage variation

IEC 61000-4-29

— 10 ms interruption on MOD power port

Corrosion resistance

classification

ISA S71.04 G2 —

North American temp

code

T4

UKEX/ATEX temp code T4

IECEx temp code T4

Enclosure type None (open-style)

Certifications - Digital I/O Modules

Certification

5069-IA16, 5069-IB16,

5069-IB16K, 5069-IB16F,

5069-IB6F-3W, 5069-OA16,

5069-OB8, 5069-OB16,

5069-OB16K, 5069-OB16F

5069-OW4I, 5069-OW16, 5069-OX4I

c-UL-us

UL Listed Industrial Control Equipment, certified for US and Canada. See UL

File E322657.

UL Listed for Class I, Division 2 Group A,B,C,D Hazardous Locations, certified

for U.S. and Canada. See UL File E334470.

UKCA and CE

UK Statutory Instrument 2016 No. 1091 and European Union 2014/30/EU EMC

Directive, compliant with:

EN 61326-1; Meas./Control/Lab., Industrial Requirements

EN 61000-6-2; Industrial Immunity

EN 61000-6-4; Industrial Emissions

EN 61131-2; Programmable Controllers (Clause 8, Zone A & B)

UK Statutory Instrument 2016 No. 1101 and European Union 2014/35/EU LVD,

compliant with:

EN 61010-2-201; Control Equipment Safety Requirements

UK Statutory Instrument 2012 No. 3032 and European Union 2011/65/EU

RoHS, compliant with:

EN IEC 63000; Technical documentation

RCM

Australian Radiocommunications Act, compliant with

EN 61000-6-4; Industrial Emissions

Ex

UK Statutory Instrument 2016 No. 1107 and European Union 2014/34/EU ATEX

Directive, compliant with:

EN IEC 60079-0; General

Requirements

EN IEC 60079-7; Explosive

Atmospheres, Protection “e”

II 3 G Ex ec IIC T4 Gc

DEMKO 15 ATEX 1484X and

UL22UKEX2379X

EN IEC 60079-0; General Requirements

EN IEC 60079-7; Explosive Atmospheres,

Protection “e”

EN IEC 60079-15; Potentially Explosive

Atmospheres, Protection “n”

II 3 G Ex ec nC IIC T4 Gc

DEMKO 15 ATEX 1484X and UL 22UKEX2379X

When used at or below 125V DC or 30V DC

IECEx

IECEx System, compliant with:

IEC 60079-0; General

Requirements

IEC 60079-7; Explosive

Atmospheres, Protection “e”

II 3 G Ex ec IIC T4 Gc

IECEx UL 15.0055X

IEC 60079-0; General Requirements

IEC 60079-7; Explosive Atmospheres,

Protection “e”

IEC 60079-15; Potentially Explosive

Atmospheres, Protection “n”

II 3 G Ex ec nC IIC T4 Gc

IECEx UL 15.0055X

When used at or below 125V DC or 30V DC

KC

Korean Registration of Broadcasting and Communications Equipment,

compliant with:

Article 58-2 of Radio Waves Act, Clause 3

Morocco

Arrêté ministériel n° 6404-15 du 1 er muharram 1437

Arrêté ministériel n° 6404-15 du 29 ramadan 1436

CCC

CNCA-C23-01:2019

CNCA-C23-01:2019 CCC Implementation Rule Explosion-Proof Electrical

Products

CCC: 2020312309000308

See the Product Certification link at rok.auto/certifications

for Declarations of Conformity,

Certificates, and other certification details.

Rockwell Automation Publication 5069-TD001O-EN-P - May 2024 7

Compact 5000 I/O Modules and EtherNet/IP Adapters

5069-IA16

Digital 16-point 120/240V AC Input Module

Functional Block Diagram - 5069-IA16

For Wiring and Installation Specifications, see page 5.

For Certifications, see page 6.

For Environmental Specifications, see page 6.

Input Wiring - 5069-IA16

IMPORTANT:

• The 5069-IA16 module uses AC SA power. You must connect AC power to the device that

supplies SA power to the module. See the SA power device list

.

• Compact GuardLogix 5380 controllers do not support AC power on their SA power RTBs.

To install a local 5069-IA16 module in a Compact GuardLogix 5380 controller system,

complete the steps in Isolate SA power

.

• The 5069-IA16 module inputs use a shared common. The inputs have a return through

internal module circuitry to the SA (–) terminal on the SA power RTB. For more

information, see Power the Compact 5000 I/O Modules

.

Technical Specifications - 5069-IA16

Attribute 5069-IA16

Number of inputs 16 (One group of 16)

Voltage category 120/240V AC

Voltage and current ratings

Input voltage range 79…264V AC

Input voltage frequency 47…63 Hz

MOD power 75 mA @ 18…32V DC

MOD power

(passthrough)

(1)

9.55 A @ 18…32V DC

SA power 240 mA @ 79…264V AC

SA power (passthrough)

(1)

9.975 A @ 79…264V AC

Do not exceed 10 A MOD or SA power (passthrough) current draw.

The 5069-IA16 module complies to UKEX/ATEX/IECEx when used at or below 125V AC.

Input 0 (I00)

Input 1 (I01)

Input 2 (I02)

Input 3 (I03)

Input 4 (I04)

Input 5 (I05)

Input 6 (I06)

Input 7 (I07)

Input 8 (I08)

Input 9 (I09)

Input 10 (I10)

Input 11 (I11)

Input 12 (I12)

Input 13 (I13)

Input 14 (I14)

Input 15 (I15)

Not used

Not used

SA+ (L1)

SA– (L2)

120V/240V AC

5

0

6

9

Current

Limiting

Input

Circuits

MOD

Power

24V DC

SA Power AC (+)

SA Power AC (–)

Input

Nonvolatile

Memory

Backplane

ASIC

Status

Indicators

Module

Power

Supply

Input

B

a

c

k

p

l

a

n

e

Backplane

Communication

I

s

o

l

a

t

i

o

n

Power dissipation, max 3.5 W

Thermal dissipation, max 11.9 BTU/hr

Isolation voltage

250V (continuous), Basic Insulation Type

Type tested at 1800V AC for 60 s

No isolation between individual channels

Indicators

1 green/red module status indicator

16 yellow/red I/O status indicators

Wire category

(2)

1 - input port

1 wire per terminal for each signal port

IEC Input Compatibility Type 1

On-state voltage, min 79V AC

On-state voltage, nom 120/240V AC

On-state voltage, max 264V AC

Off-state voltage, max 40V AC

Input current per channel,

max

15 mA @ 264V AC

On-state current, min

2 mA @ 79V AC

3 mA @ 164V AC

On-state current, nom

5 mA @ 120V AC/50 Hz

6 mA @ 120V AC/60 Hz

9 mA @ 240V AC/50 Hz

11 mA @ 240V AC/60 Hz

On-state current, max 15 mA @ 264V AC

Off-state current, max 2 mA

Input impedance, nom

24 kΩ @ 120V AC/50 Hz

20 kΩ @ 120V AC/60 Hz

27 kΩ @ 240V AC/50 Hz

22 kΩ @ 240V AC/60 Hz

Input impedance, min 17.6 kΩ @ 264V AC/63 Hz

Inrush current, max 600 mA

Input delay time,

Off to On and On to Off

10 ms (typ) @ 0...60 °C (32…140 °F)

Input filter times

Off to On

Hardware delay: 10 ms (typ) + filter time

User-selectable filter times:

120V AC input - 1 ms

240V AC input - 1 ms, 2 ms, 5 ms

On to Off

Hardware delay: 10 ms (typ) + filter time

User-selectable filter times:

120V AC input - 10 ms, 20 ms

240V AC input - 5 ms, 10 ms, 20 ms

With the 5069-IA16 module, the Logix Designer application lets you choose multiple filter

values, including values that are invalid for some input signals. For example, the only valid

Off to On filter value when a 120V AC signal is connected to the module is 1 ms. However, you

can choose 1 ms, 2 ms, or 5 ms. If you select an invalid input filter value, the module can

read signal levels incorrectly. For more information, see the Compact 5000 I/O Digital

Modules User Manual, publication 5069-UM004

.

(1) The level of Mod power or SA power current that passes through the module. This level

depends on the system configuration, such as, module slot location and the other

module types that are used in the system. For more information, see the controller user

manuals in the Additional Resources

.

(2) Use this Conductor Category information to plan conductor routes. See the Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1.

Technical Specifications - 5069-IA16

Attribute 5069-IA16

8 Rockwell Automation Publication 5069-TD001O-EN-P - May 2024

Compact 5000 I/O Modules and EtherNet/IP Adapters

5069-IB16, 5069-IB16K, 5069-IB16F

Digital 16-point Sinking Input Modules

Functional Block Diagram - 5069-IB16, 5069-IB16K, 5069-IB16F

For Wiring and Installation Specifications, see page 5.

For Certifications, see page 6.

For Environmental Specifications, see page 6.

Input Wiring - 5069-IB16, 5069-IB16K, 5069-IB16F

IMPORTANT:

• These modules use DC SA power. You must connect DC power to the device that supplies

SA power to the module. See the SA power device list

and Isolate SA power.

• The 5069-IB16 and 5069-IB16F module inputs use a shared common. The inputs have a

return through internal module circuitry to the SA (–) terminal on the SA power RTB. For

more information, see Power the Compact 5000 I/O Modules

.

Technical Specifications - 5069-IB16, 5069-IB16K, and 5069-IB16F

Attribute 5069-IB16, 5069-IB16K 5069-IB16F

Inputs 16 Channels (1 group of 16), sinking

Voltage category 12/24V DC Sink

Voltage and current ratings

Input ratings 4…7.4 mA per channel @ 10…32V DC

MOD power 75 mA @ 18…32V DC

MOD power (passthrough)

(1)

9.55 A @ 18…32V DC

SA power 200 mA @ 10…32V DC

SA power (passthrough)

(1)

9.95 A @ 10…32V DC

Power dissipation, max 3.9 W

Thermal dissipation, max 13.3 BTU/hr

Isolation voltage

250V (continuous), Basic Insulation Type

No isolation between SA power and input ports

No isolation between individual input ports

Input 0 (I00)

Input 1 (I01)

Input 2 (I02)

Input 3 (I03)

Input 4 (I04)

Input 5 (I05)

Input 6 (I06)

Input 7 (I07)

Input 8 (I08)

Input 9 (I09)

Input 10 (I10)

Input 11 (I11)

Input 12 (I12)

Input 13 (I13)

Input 14 (I14)

Input 15 (I15)

Not used

Not used

DC (+)

2-wire

Sensor

3-wire

Sensor

DC (–)

Transient

Suppression

5

0

6

9

Current

Limiting

Input

Circuits

MOD

Power

24V DC

SA Power DC (+)

SA Power DC (–)

Input

Nonvolatile

Memory

Backplane

ASIC

Status

Indicators

Module

Power

Supply

Input

B

a

c

k

p

l

a

n

e

Backplane

Communication

I

s

o

l

a

t

i

o

n

Indicators

1 green/red module status indicator

16 yellow/red I/O status indicators

Wire category

(2)

2 - input ports

1 wire per terminal for each signal port

On-state voltage, min 10V DC

On-state voltage, nom 24V DC

On-state voltage, max 32V DC

On-state current, min 4 mA @ 10V

On-state current, nom 6 mA @ 24V DC

On-state current, max 7.4 mA @ 32V DC

Off-state voltage, max 5V DC

Off-state current, max 1.5 mA

Input impedance, min 1.33 kΩ

Input impedance, nom 4.1 kΩ

Input impedance, max 7.0 kΩ

Inrush current, max

< 250 mA peak (decaying to, 37% in 22 ms, without

activation)

Input delay time

(screw to backplane)

Off to On and On to Off

≤ 100 µs, ±10 µs @

25 °C (77 °F)

≤ 10 µs, ±1 µs @

25 °C (77 °F)

Input drift over temperature

span

±100 ns/°C (55.6 ns/°F)

from 0…60 °C (32…140 °F)

< 10 ns/°C (5.56 ns/°F)

from 0…60 °C (32…140 °F)

Input pulse width, min

Off to ON and ON to Off

60 µs 6 µs

Input filter time

Off to On and On to Off

Hardware delay:

50 µs + filter time

User-selectable filter

time:

0…50 ms

Hardware delay:

Off to On - 2 µs + filter time

On to Off - 3 µs + filter time

User-selectable filter time:

0…50 ms

Reverse polarity protection Yes

Overvoltage protection, max 36V (fuse protected)

Counter frequency

0 - f

max

= 500 Hz

(Inv period 2 ms)

0 - f

max

= 30 kHz

(Inv period 33.3 µs)

Frequency counter

0 - f

max

= 500 Hz

(Inv period 2 ms)

0 - f

max

= 30 kHz

(Inv period 33.3 µs)

Pulse and period

measurements

–

±2 µs

Time stamp of inputs

±10 µs accuracy

1 ns resolution

Pulse latching Supported

Events

4 events supported (triggered by

any input or simple counters)

Pattern matching Supported

Features, not suported

The modules do not support these features.

•Overrides

• Extended counters

(1) The level of Mod power or SA power current that passes through the module. This level

depends on the system configuration, such as, module slot location and the other

module types that are used in the system. For more information, see the controller user

manuals in the Additional Resources

.

(2) Use this Conductor Category information to plan conductor routes. See the Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1.

Technical Specifications - 5069-IB16, 5069-IB16K, and 5069-IB16F

Attribute 5069-IB16, 5069-IB16K 5069-IB16F

Rockwell Automation Publication 5069-TD001O-EN-P - May 2024 9

Compact 5000 I/O Modules and EtherNet/IP Adapters

5069-IB6F-3W

Digital 3-wire Sinking Input Module

Functional Block Diagram - 5069-IB6F-3W

For Wiring and Installation Specifications, see page 5.

For Certifications, see page 6.

For Environmental Specifications, see page 6

.

Input Wiring - 5069-IB6F-3W

IMPORTANT:

The 5069-IB6F-3W module uses DC SA power. You must connect DC power to the device that

supplies SA power to the module. See the SA power device list

and Isolate SA power.

Technical Specifications - 5069-IB6F-3W

Attribute 5069-IB6F-3W

Inputs 6 Channels (1 group of 6), sinking

Voltage category 12/24V DC Sink

Voltage and current ratings

Input ratings 4…7.4 mA per channel @ 10…32V DC

Output supply ratings

150 mA per channel @ 10…32V DC

900 mA per module @ 10…32V DC

MOD power 75 mA @ 18V…32V DC

MOD power (passthrough)

(1)

9.55 A @ 18…32V DC

SA power 900 mA @ 10…32V DC

SA power (passthrough)

(1)

9.95 A @ 10…32V DC

Do not exceed 10 A MOD or SA power (passthrough) current draw.

Input 0 (I00)

SA+ (24V DC)

SA- (24V DC Return)

Input 1 (I01)

SA+ (24V DC)

SA- (24V DC Return)

Input 2 (I02)

SA+ (24V DC)

SA- (24V DC Return)

Input 3 (I03)

SA+ (24V DC)

Input 4(I04)

SA+ (24V DC)

SA- (24V DC Return)

Input 5 (I05)

SA+ (24V DC)

SA- (24V DC Return)

SA- (24V DC Return)

3-wire

Sensor

2-wire

Sensor

3-wire

Sensor

Transient

Suppression

Input

Prot DC (+)

Prot DC (Return)

5

0

6

9

Current

Limiting

Input

Circuits

MOD

Power

24V DC

SA Power DC (+)

SA Power DC (–)

Nonvolatile

Memory

Backplane

ASIC

Status

Indicators

Module

Power

Supply

B

a

c

k

p

l

a

n

e

Backplane

Communication

I

s

o

l

a

t

i

o

n

Power dissipation, max 2.4 W

Thermal dissipation, max 8.1 BTU/hr

Isolation voltage

250V (continuous), Basic Insulation Type

No isolation between SA power and input ports

No isolation between individual input ports

Indicators

1 green/red module status indicator

6 yellow/red I/O status indicators

Wire category

(2)

2 - input ports

2 - power ports

1 wire per terminal for each signal port

On-state voltage, range 10V DC…32V DC

On-state voltage, nom 24V DC

Off-state voltage, max 5V DC

On-state current, min 4 mA @ 10V DC

On-state current, nom 6 mA @ 24V DC

On-state current, max 7.4 mA @ 32V DC

Off-state current, max 1.5 mA

Input impedance, nom 4.1 kΩ

Input impedance, max 7.0 kΩ

Inrush current, max

< 250 mA peak (decaying to, 37% in 22 ms, without

activation)

Input delay time

(screw to backplane)

Off to On and On to Off

≤ 10 µs, ±1 µs @ 25 °C (77 °F)

Input drift over temperature

span

±10 ns/°C (5.56 ns/°F) from 0…60 °C (32…140 °F)

Input minimum pulse width

Off to On and On to Off

6 µs

Input filter time

Hardware delay Off to On: 2 µs + filter time

Hardware delay On to Off: 3 µs + filter time

User-selectable filter time Off to On and On to Off: 0…50 ms

Reverse polarity protection Yes

Overvoltage protection, max 36V (fuse protected)

Pulse width and period

measurements

±2 µs

Simple counters

Counter frequency

0 - f

max

= 30 kHz (Inv period 33.3 µs)

Frequency counter

0 - f

max

= 30 kHz (Inv period 33.3 µs)

Time stamp of inputs

±10 µs accuracy

1 ns resolution

Events

4 events supported

(triggered by any input or simple counters)

Features, suported

The module supports these features.

• Pulse latching

•Pattern matching

Features, not suported

The module does not support these features.

• Overrides

•Extended counters

(1) The level of Mod power or SA power current that passes through the module. This level

depends on the system configuration, such as, module slot location and the other module

types that are used in the system. For more information, see the controller user manuals

in the Additional Resources

.

(2) Use this Conductor Category information to plan conductor routes. See the Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1.

Technical Specifications - 5069-IB6F-3W

Attribute 5069-IB6F-3W

10 Rockwell Automation Publication 5069-TD001O-EN-P - May 2024

Compact 5000 I/O Modules and EtherNet/IP Adapters

5069-OA16

Digital 16-point 120/240V AC Output Module

Functional Block Diagram - 5069-OA16

For Wiring and Installation Specifications, see page 5.

For Certifications, see page 6.

For Environmental Specifications, see page 6.

Output Wiring - 5069-OA16

IMPORTANT:

• The 5069-OA16 module uses AC SA power. You must connect AC power to the device that

supplies SA power to the module. See the SA power device list

and Isolate SA power.

• Compact GuardLogix 5380 controllers do not support AC power on their SA power RTBs.

To install a local 5069-OA16 module in a Compact GuardLogix 5380 controller system,

complete the steps in Isolate SA power

.

• The 5069-OA16 module outputs use a shared common. The outputs have a return through

internal module circuitry to the SA (–) terminal on the SA power RTB. For more

information, see Power the Compact 5000 I/O Modules

.

Technical Specifications - 5069-OA16

Attribute 5069-OA16

Number of outputs 16 (One group of 16)

Voltage category 120/240V AC

Voltage and current ratings

Output voltage range 85…264V AC

Output voltage frequency 47…63 Hz

MOD power 100 mA @ 18…32V DC

MOD power (passthrough)

(1)

9.55 A @ 18…32V DC

SA power 4 A @ 85…264V AC

SA power (passthrough)

(1)

9.975 A @ 85…264V AC

Do not exceed 10 A MOD or SA power (passthrough) current draw.

The 5069-OA16 module complies to UKEX/ATEX/IECEx when used at or below 125V AC.

Output 0 (O00)

Output 1 (O01)

Output 2 (O02)

Output 3 (O03)

Output 4 (O04)

Output 5 (O05)

Output 6 (O06)

Output 7 (O07)

Output 8 (O08)

Output 9 (O09)

Output 10 (O10)

Output 11 (O11)

Output 12 (O12)

Output 13 (O13)

Output 14 (O14)

Output 15 (O15)

Not used

Not used

120/240V AC

CR

CR

CR

CR

SA+ (L1)

SA- (L2)

Field Power

Loss Detection

Circuitry

Output

Output

Circuitry

SA+ (L1)

SA- (L2)

Isolation

5

0

6

9

MOD

Power

24V DC

Nonvolatile

Memory

Backplane

ASIC

Status

Indicators

Module

Power

Supply

B

a

c

k

p

l

a

n

e

Backplane

Communication

I

s

o

l

a

t

i

o

n

Power dissipation, max 3.4 W

Thermal dissipation, max 11.6 BTU/hr

Isolation voltage

250V (continuous), Basic Insulation Type

Type tested at 1800V AC for 60 s

No isolation between individual channels

Indicators

1 green/red module status indicator

16 yellow/red I/O status indicators

Wire category

(2)

1 - output port

1 - power port

1 wire per terminal for each signal port

On-state voltage, min 85V AC

On-state voltage, nom 120/240V AC

On-state voltage, max 264V AC

On-state voltage drop, max 1.5V AC @ 0.5 A

Output current per channel, max 0.5 A

Output current per module, max 4 A

Off-state leakage current, max

1 mA

NOTE: To limit the effects of leakage current through

solid-state outputs, you can connect a loading resistor in

parallel with your load. For 120V AC operation, use a 15

KΩ, 2 W resistor. For 240V AC operation, use a 15 KΩ, 5 W

resistor.

Surge current per point 5 A max for 25 ms per point, repeatable every 2 s

Output delay time

(backplane to screw)

Off to On and On to Off

1/2 cycle time (typ) @ 0...60 °C (32…140 °F)

Field power loss detection Yes

Features, not supported

The module does not support these features.

• No load detection per channel diagnostics

• Output short circuit/overload/overtemp detection per

channel diagnostics

• Output short circuit/overload protection

• Reverse voltage protection

• Overvoltage protection

• Scheduled outputs

Pilot duty rating

Resistive/General Pilot Duty

0.5 A pilot duty

Output control in fault state

per point

•Hold Last State

•On

• Off (default)

Output states in program mode

per point

Output states in fault mode

per point

Duration of fault mode

per point

• 1, 2, 5, or 10 seconds

• Forever (default)

(1) The level of Mod power or SA power current that passes through the module. This level

depends on the system configuration, such as, module slot location and the other module

types that are used in the system. For more information, see the controller user manuals

in the Additional Resources

.

(2) Use this Conductor Category information to plan conductor routes. See the Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1.

Technical Specifications - 5069-OA16

Attribute 5069-OA16

Rockwell Automation Publication 5069-TD001O-EN-P - May 2024 11

Compact 5000 I/O Modules and EtherNet/IP Adapters

5069-OB8

Digital 8-point 24V DC Output Module

Functional Block Diagram - 5069-OB8

For Wiring and Installation Specifications, see page 5.

For Certifications, see page 6

.

For Environmental Specifications, see page 6.

Output Wiring - 5069-OB8

IMPORTANT:

• The 5069-OB8 module does not draw current from the SA power bus. Still, the module is a

DC-type module, and you must install it on a DC SA power bus.

• The LA+ and LA – connections are used to supply field-side power to the module. Output

channels 0…3 use LA0 +/–, and output channels 4…7 use LA1 +/–.

Technical Specifications - 5069-OB8

Attribute 5069-OB8

Number of outputs 8 (two groups of 4)

Voltage category 24V DC

Voltage and current ratings

Output voltage range 10…32V DC

MOD power 75 mA @ 18…32V DC

MOD power (passthrough)

(1)

9.55 A @ 18…32V DC

LA power

2 A per channel @ 10…32V DC

8 A per group @ 10…32V DC

16 A per module @ 10…32V DC

SA power (passthrough)

(1)

9.95 A @ 10…32V DC

NOTE: The module does not draw SA power current.

Do not exceed 10 A MOD or SA power (passthrough) current draw.

Power dissipation, max 3.2 W

Thermal dissipation, max 10.9 BTU/hr

+

–

Output 0 (O00)

Output 1 (O01)

Output 2 (O02)

Output 3 (O03)

LA0 –

LA0 –

LA0 –

LA0 –

LA0 +

Output 4 (O04)

Output 5 (005)

Output 6 (006)

Output 7 (007)

LA1 –

LA1 –

LA1 –

LA1 –

LA1 +

CR

24V DC

24V DC to

5V DC

Converter

Inductive

Kickback

Suppression

Soft Start

Circuitry

Output

LAx +

LAx -

Output

Circuitry

5

0

6

9

MOD

Power

24V DC

Nonvolatile

Memory

Backplane

ASIC

Status

Indicators

Module

Power

Supply

B

a

c

k

p

l

a

n

e

Backplane

Communication

I

s

o

l

a

t

i

o

n

Isolation voltage

250V (continuous), Basic Insulation Type

Type tested at 1800V AC for 60 s

No isolation between LA power and output ports

No isolation between individual output ports

Indicators

1 green/red module status indicator

8 yellow/red I/O status indicators

Wire category

(2)

2 - output ports

2 - power ports

1 wire per terminal for each signal port

LA power attributes

On-state voltage, min 10V DC

On-state voltage, nom 24V DC

On-state voltage, max 32V DC

On-state voltage drop, max 0.25V DC

Off-state voltage, max < 10V DC

On-state current per channel, min 1 mA

Off-state leakage current

per point, max

0.5 mA

NOTE: To limit the effects of leakage current

through solid-state outputs, you can connect a

loading resistor in parallel with your load. For 24V DC

operation, use a 5.6 KÙ, 0.5 W resistor for transistor

outputs.

Output current per channel, max 2 A

Output current per group, max 8 A

Output current per module, max 16 A

Surge current per point 4 A max for 10 ms per point, repeatable every 2 s

Output delay time (backplane to

screw)

Off to On and On to Off

≤ 100 µs @ 25 °C (77 °F) @ 2 A

Pulse width, min

≤ 200 µs T

on

min + T

off

min @ 2 A @ 25 °C (77 °F)

Output drift over temperature span

±100 ns/°C (55.6 n/°F)

from 0…60 °C (32…140 °F) @ 2 A

Features, supported

The module supports these features.

• Field power loss detection

• No load detection per channel diagnostics

• Output short circuit/overload/overtemp

detection per channel diagnostics

• Output short circuit/overload protection

• Reverse voltage protection

Overvoltage protection, max 36V (fuse protected)

Pilot duty rating

Resistive/General Pilot Duty

2 A pilot duty

Output control in fault state per point

•Hold Last State

•On

• Off (default)

Output states in program mode

per point

Output states in fault mode per point

Duration of fault mode per point

• 1, 2, 5, or 10 seconds

• Forever (default)

(1) The level of Mod power or SA power current that passes through the module. This level

depends on the system configuration, such as, module slot location and the other

module types that are used in the system. For more information, see the controller user

manuals in the Additional Resources

.

(2) Use this Conductor Category information to plan conductor routes. See the Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1.

Technical Specifications - 5069-OB8

Attribute 5069-OB8

12 Rockwell Automation Publication 5069-TD001O-EN-P - May 2024

Compact 5000 I/O Modules and EtherNet/IP Adapters

5069-OB16, 5069-OB16K, 5069-OB16F

Digital 16-point Sourcing Output Modules

Functional Block Diagram - 5069-OB16, 5069-OB16K, 5069-OB16F

For Wiring and Installation Specifications, see page 5.

For Certifications, see page 6.

For Environmental Specifications, see page 6.

Output Wiring - 5069-OB16, 5069-OB16K, 5069-OB16F

IMPORTANT:

• These modules do not draw current from the SA power bus. Still, the modules are DC-type

modules, and you must install them on a DC SA power bus.

• The LA+ and LA- connections are used to supply field-side power to the module.

Technical Specifications - 5069-OB16, 5069-OB16K, 5069-OB16F

Attribute 5069-OB16, 5069-OB16K 5069-OB16F

Outputs 16 Channels (1 group of 16), sourcing

Voltage category 12/24V DC source

Voltage and current ratings

MOD power 75 mA @ 18…32V DC

MOD power (passthrough)

(1)

9.55 A @ 18…32V DC

LA Power

0.5 A per channel @ 10…32V DC

8 A per module @ 10…32V DC

SA power (passthrough)

(1)

9.95 A @ 10…32V DC

NOTE: The module does not draw SA power current.

Do not exceed 10 A MOD or SA power (passthrough) current draw

Power dissipation, max 3.25 W (16 channels @ 0.5 A)

Thermal dissipation, max 11.09 BTU/hr

Output 0 (O00)

Output 1 (O01)

Output 2 (O02)

Output 3 (O03)

Output 4 (O04)

Output 5 (O05)

Output 6 (O06)

Output 7 (O07)

Output 8 (O08)

Output 9 (O09)

Output 10 (O10)

Output 11 (O11)

Output 12 (O12)

Output 13 (O13)

Output 14 (O14)

Output 15 (O15)

LA+

LA-

LA-

24V DC

+

–

TB-16

TB-17

24V DC to

5V DC

Converter

Inductive

Kickback

Suppression

Soft Start

Circuitry

Output

LA +

LA -

Output

Circuitry

5

0

6

9

MOD

Power

24V DC

Nonvolatile

Memory

Backplane

ASIC

Status

Indicators

Module

Power

Supply

B

a

c

k

p

l

a

n

e

Backplane

Communication

I

s

o

l

a

t

i

o

n

Isolation voltage

250V (continuous), Basic Insulation Type

No isolation between LA power and output ports

No isolation between individual output ports

Indicators

1 green/red module status indicator

16 yellow/red I/O status indicators

Wire category

(2)

2 - output ports

2 - power ports

1 wire per terminal for each signal port

LA power attributes

On-state voltage, min 10V DC

On-state voltage, nom 24V DC

On-state voltage, max 32V DC

On-state voltage drop, max < 0.2V DC

On-state current per

channel, min

1 mA

Off-state voltage, max 5V DC with 1 mA min load

Off-state leakage current per

point, max

< 0.5 mA per point

NOTE: To limit the effects of leakage current through solid-

state outputs, you can connect a loading resistor in parallel

with your load. For 24V DC operation,

use a 5.6 KÙ, 0.5 W resistor for transistor operation.

Output current rating

0.5 A resistive per channel @ 10…32V DC

8 A resistive per module @ 10…32V DC, max

Surge current per point 1 A max for 10 ms per point, repeatable every 2 s

Output delay time

(backplane to screw)

Off to On and On to Off

≤ 100 µs, ±10 µs

@ 25 °C (77 °F) @ 0.5 A

10 µs, ±1 µs

@ 25 °C (77 °F) @ 0.5 A

Pulse width, min

200 µs @ 0.5 A

@ 25 °C (77 °F)

20 µs @ 0.5 A

@ 25 °C (77 °F)

Output drift over temperature

span

±100 ns/°C (55.6 ns/°F) from

0…60 °C (32…140 °F) @ 0.5 A

±10 ns/°C (5.56 ns/°F) from

0…60 °C (32…140 °F) @ 0.5 A

Features, supported

The modules support these features.

• Field power loss detection (Series B hardware only)

• No load detection per channel diagnostics

• Output short circuit/overload/overtemp detection per

channel diagnostics

• Output short circuit/overload protection

• Reverse voltage protection

Overvoltage protection, max 36V (fuse protected)

Pilot duty rating 0.5 A pilot duty rating per channel @ 10…32V DC

Output control in fault state

per point

•Hold Last State

•On

• Off (default)

Output states in program

mode per point

Output states in fault mode

per point

Duration of fault mode per

point

• 1, 2, 5, or 10 seconds

• Forever (default)

Scheduled outputs –

±10 µs accuracy

1 ns resolution

(1) The level of Mod power or SA power current that passes through the module. This level

depends on the system configuration, such as, module slot location and the other

module types that are used in the system. For more information, see the controller user

manuals in the Additional Resources

.

(2) Use this Conductor Category information to plan conductor routes. See the Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1

.

Technical Specifications - 5069-OB16, 5069-OB16K, 5069-OB16F

Attribute 5069-OB16, 5069-OB16K 5069-OB16F

Rockwell Automation Publication 5069-TD001O-EN-P - May 2024 13

Compact 5000 I/O Modules and EtherNet/IP Adapters

5069-OW4I

Digital 4-point Isolated Relay Output Module

Functional Block Diagram - 5069-OW4I

Output Wiring - 5069-OW4I

IMPORT

ANT:

The 5069-OW4I module does not draw current from the SA power bus. Still, the module is a

DC-type module, and you must install it on a DC SA power bus.

Technical Specifications - 5069-OW4I

Attribute 5069-OW4I

Outputs 4 - Form A (normally open)

Voltage and current ratings

Output voltage range

5…125V DC

5…264V AC

MOD power 75 mA @ 18…32V DC

MOD power (passthrough)

(1)

9.55 A @ 18…32V DC

SA power (passthrough)

(1)

9.95 A @ 0…32V DC

NOTE: The module does not draw SA power current.

Do not exceed 10 A MOD or SA power (passthrough) current draw

Power dissipation, max 2.3 W

Thermal dissipation, max 7.85 BTU/hr

Isolation voltage 250V (continuous), Basic Insulation Type

Indicators

1 green/red module status indicator

4 yellow/red I/O status indicators

0 A

0 B

1 A

1 B

2 A

2 B

3 A

3 B

Power

Supply

Load

Terminals are not used

0 A

0 B

SA Power

24V DC

5

0

6

9

MOD

Power

24V DC

Nonvolatile

Memory

Backplane

ASIC

Status

Indicators

Module

Power

Supply

B

a

c

k

p

l

a

n

e

Backplane

Communication

Wire category

(2)

1 - relay port

1 wire per terminal for each signal port

Relay rating

2 A resistive per channel @ 5…30V DC

2 A resistive per channel @ 5…264V AC, 50/60 Hz

2 A general use per channel @ 5…250V AC, 50/60 Hz

2 A @ 5…125V AC, UKEX/ATEX/IECEx

8 A per module, max

NOTE: To extend the life of the module, connect surge

suppressors across your external inductive load. For

additional details, see the Industrial Automation Wiring and

Grounding Guidelines, publication 1770-4.1

.

Off-state leakage 0 mA (dry contact, no onboard snubbers)

Output current rating, max

2 A per channel

8 A per module

Output delay time, max

Off to On 10 ms

On to Off 10 ms

Switching frequency 1 operation every 3 seconds (0.3 Hz at rated load)

Initial contact resistance, max 30 mΩ

Bounce time, mean 500 µs

Output control in fault state

per point

• Hold last state

•On

• Off (default)

Output states in program

mode per point

Output states in fault mode

per point

Duration of fault mode per

point

• 1, 2, 5, or 10 seconds

• Forever (default)

Delay to fault Supported

Fusing Outputs are not fused.

Minimum load current 1 mA

Expected contact life 300K cycles resistive, 100K cycles inductive

Pilot duty rating

5…240V AC, 50/60 Hz, C300 pilot duty per channel

5…125V DC, R150 pilot duty per channel

(1) The level of Mod power or SA power current that passes through the module. This level

depends on the system configuration, such as, module slot location and the other

module types that are used in the system. For more information, see the controller user

manuals in the Additional Resources

table.

(2) Use this Conductor Category information to plan conductor routes. See the Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1.

Technical Specifications - 5069-OW4I

Attribute 5069-OW4I

For Wiring and Installation Specifications, see page 7.

For Certifications, see page 8.

For Environmental Specifications, see page 8.

Relay Contact Ratings - 5069-OW4I

Volts,

Max

Continuous

Amps per

Point, Max

Amperes Voltamperes

NEMA

ICS 2-125

Make Break Make Break

240V AC

2 A

7.5 A 0.75 A

1800VA 180VA C300

120V AC 15 A 1.5 A

125V DC

0.27 A

(1)

0.22 A

(2)

28VA R150

24V DC 2.0 A

1.16 A

(2)

28VA -

(1) Calculated based on the Rockwell Automation component derating guideline:

90% of rated contact current, that is, 0.3 A at 125V DC.

(2) For DC voltage applications, to determine the make/break ampere rating for relay

contacts, divide 28VA by the applied DC voltage. For example, 28VA/48V DC = 0.58 A.

14 Rockwell Automation Publication 5069-TD001O-EN-P - May 2024

Compact 5000 I/O Modules and EtherNet/IP Adapters

5069-OW16

Digital 16-point Relay Output Module

Functional Block Diagram - 5069-OW16 Series A and Series B

Functional Block Diagram - 5069-OW16 Series C

Output Wiring - 5069-OW16

IMPORTANT:

• The 5069-OW16 Series A and Series B modules require DC SA power. You must connect DC

power to the device that supplies SA power to the module. See the SA power device list

and Isolate SA power.

• The 5069-OW16 Series C module does not use SA power. That is, it does not draw current

from the SA power bus. The module passes it through to the next Compact 5000 I/O

module in the system.

• You can connect AC-type devices, DC-type devices, or a combination of the two types.

• The module has two commons, each is shared across a set of eight output channels.

– Common 0 is shared across Outputs 0…7

– Common 1 is shared across Outputs 8…15

Do not connect devices of different power types to channels that share a common.

0

7

6

5

4

3

2

1

17

16

15

14

13

12

11

10

9

8

Output 0

Output 1

Output 2

Output 3

Output 4

Output 5

Output 6

Output 7

Common 0

Output 8

Output 9

Output 10

Output 11

Output 12

Output 13

Output 14

Output 15

Common 1

CR

CR

AC-type

Power

Supply

DC-type

Power

Supply

L1

L2

+24V DC

-24V DC

CR

CR

Common x

Output

Channel x

SA Power

Supply

SA Power

24V DC

5

0

6

9

MOD

Power

24V DC

Nonvolatile

Memory

Backplane

ASIC

Status

Indicators

Module

Power

Supply

B

a

c

k

p

l

a

n

e

Backplane

Communication

Common x

Output

Channel x

SA Power

MOD

Power

24V DC

Nonvolatile

Memory

Backplane

ASIC

Status

Indicators

Module

Power

Supply

Backplane

Communication

I/O Power

Supply

5

0

6

9

B

a

c

k

p

l

a

n

e

Rockwell Automation Publication 5069-TD001O-EN-P - May 2024 15

Compact 5000 I/O Modules and EtherNet/IP Adapters

T

echnical Specifications - 5069-OW16

Attribute 5069-OW16

Outputs 16 (Two groups of 8) - Form A (normally open)

Voltage and current ratings

Output voltage range 5…125V DC, 5…264V AC

MOD power

Series A and B: 75 mA @ 18…32V DC

Series C: 225 mA @ 18…32V DC

MOD power (passthrough)

(1)

9.55 A @ 18…32V DC

SA power

Series A and B: 150 mA @ 18…32V DC

Series C: –

SA power (passthrough)

(1)

9.95 A @ 18…32V DC

Do not exceed 10 A MOD or SA power (passthrough) current draw.

The module complies with UKEX/ATEX/IECEx when used at or below 125V AC or 30V DC.

Power dissipation, max 3.0 W

Thermal dissipation, max 10.2 BTU/hr

Isolation voltage

250V (continuous), Basic Insulation Type

Type tested at 1800V AC for 60 s

No isolation between individual channels

Module keying Electronic keying via programming software

Indicators

1 green/red module status indicator

16 yellow/red I/O status indicators

Wire category

(2)

1 - relay port

1 - power port

1 wire per terminal for each signal port

Relay ratings

2 A resistive per channel @ 5…30V DC

2 A resistive per channel @ 5…264V AC, 50/60 Hz

2 A general use per channel @ 5…250V AC, 50/60 Hz

2 A @ 5…125V AC, UKEX/ATEX/IECEx

NOTE: To extend the life of the module, connect surge

suppressors across your external inductive load. For

additional details, see the Industrial Automation Wiring

and Grounding Guidelines, publication 1770-4.1

.

Off-state leakage current per

point, max

Series A: 0 mA (dry contact, no onboard snubbers)

Series B and Series C: 0 mA (with onboard TVS snubber)

Output current per group, max 8 A

Output current per module, max 16 A

Output delay time, max

Off to On 10 ms

On to Off 10 ms

Switching frequency 1 operation every 3 seconds (0.3 Hz at rated load)

Initial contact resistance, max 30 mΩ

Bounce time, mean 500 µs

Delay to fault Supported

Fusing Outputs are not fused

Minimum load current 1 mA

Expected contact life 300K cycles resistive, 100K cycles inductive

Pilot duty rating

5…240V AC, 50/60 Hz, C300 pilot duty per channel

5…125V DC, R150 pilot duty per channel

Output control in fault state per

point

•Hold Last State

•On

• Off (default)

Output states in program mode

per point

Output states in fault mode per

point

Duration of fault mode per

point

• 1, 2, 5, or 10 seconds

• Forever (default)

(1) The level of Mod power or SA power current that passes through the module. This level

depends on the system configuration, such as, module slot location and the other

module types that are used in the system. For more information, see the controller user

manuals in the Additional Resources

table.

(2) Use this Conductor Category information to plan conductor routes. See the Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1.

Technical Specifications - 5069-OW16

Attribute 5069-OW16

For Wiring and Installation Specifications, see page 7.

For Certifications, see page 8.

For Environmental Specifications, see page 8.

Relay Contact Ratings - 5069-OW16

Volts,

Max

Continuous

Amps per

Point, Max

Amperes Voltamperes

NEMA

ICS 2-125

Make Break Make Break

240V AC

2 A

7.5 A 0.75 A

1800VA 180VA C300

120V AC 15 A 1.5 A

125V DC

0.27 A

(1)

0.22 A

(2)

28VA R150

24V DC 2.0 A

1.16 A

(2)

28VA -

(1)

(2)

Calculated based on the Rockwell Automation component derating guideline:

90% of rated contact current, that is, 0.3 A at 125V DC.

For DC voltage applications, to determine the make/break ampere rating for relay

contacts, divide 28VA by the applied DC voltage. For example, 28VA/48V DC = 0.58 A.

16 Rockwell Automation Publication 5069-TD001O-EN-P - May 2024

Compact 5000 I/O Modules and EtherNet/IP Adapters

5069-OX4I

Digital 4-point Isolated Normally-open/Normally-closed Output Module

Functional Block Diagram - 5069-OX4I

Output Wiring - 5069-OX4I

IMPORTAN

T:

The module does not draw current from the SA power bus. Still, the module is a DC-type

module, and you must install it on a DC SA power bus. See the SA power device list

and

Isolate SA power.

Technical Specifications - 5069-OX4I

Attribute 5069-OX4I

Outputs 4 - Form C (SPDT)

Voltage and current ratings

Output voltage range

5…125V DC

5…264V AC

MOD power 75 mA @ 18…32V DC

MOD power (passthrough)

(1)

9.55 A @ 18…32V DC

SA power (passthrough)

(1)

9.95 A @ 0…32V DC

NOTE: The module does not draw SA power current.

Do not exceed 10 A MOD or SA power (passthrough) current draw

Power dissipation, max 2.6 W

Thermal dissipation, max 8.88 BTU/hr

Isolation voltage 250V (continuous), Basic Insulation Type

Indicators

1 green/red module status indicator

4 yellow/red I/O status indicators

0 COMMON

1 COMMON

2 COMMON

0 N.C.

0 N.O.

1 N.C.

1 N.O.

2 N.C.

2 N.O.

3 N.C.

3 N.O.

3 COMMON

Power

Supply

Load

Power

Supply

Load

Terminals

are not used

0 N.C.

0 N.O.

0 COMMON

SA Power

24V DC

5

0

6

9

MOD

Power

24V DC

Nonvolatile

Memory

Backplane

ASIC

Status

Indicators

Module

Power

Supply

B

a

c

k

p

l

a

n

e

Backplane

Communication

Wire category

(2)

1 - relay port

1 - power port

1 wire per terminal for each signal port

Contact current rating

2 A resistive per channel @ 5…30V DC

2 A resistive per channel @ 5…264V AC, 50/60 Hz

2 A general use per channel @ 5…250V AC, 50/60 Hz

2 A @ 5…125V AC, UKEX/ATEX/IECEx

8 A per module, max

NOTE: To extend the life of the module, connect

surge suppressors across your external inductive

load. For additional details, see the Industrial

Automation Wiring and Grounding Guidelines,

publication 1770-4.1

.

Off-state leakage 0 mA (dry contact, no onboard snubbers)

Output current rating

2 A per channel

8 A per module, max

Output delay time, max

Off to On 15 ms

On to Off 15 ms

Switching frequency 1 operation every 3 seconds (.3 Hz at rated load)

Initial contact resistance, max 30 mΩ

Bounce time, mean 500 µs

Output control in fault state per point

• Hold last state

•On

• Off (default)

Output states in program mode per

point

Output states in fault mode per point

Duration of fault mode per point

• 1, 2, 5, or 10 seconds

• Forever (default)

Delay to fault Supported

Fusing Outputs are not fused

Minimum load current 10 mA

Expected contact life 300K cycles resistive, 100K cycles inductive

Pilot duty rating

5…240V AC, 50/60 Hz, C300 pilot duty per channel

5…125V DC, R150 pilot duty per channel

(1) The level of Mod power or SA power current that passes through the module. This level

depends on the system configuration, such as, module slot location and the other

module types that are used in the system. For more information, see the controller user

manuals in the Additional Resources

table.

(2) Use this Conductor Category information to plan conductor routes. See the Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1

.

Technical Specifications - 5069-OX4I

Attribute 5069-OX4I

For Wiring and Installation Specifications, see page 7.

For Certifications, see page 8.

For Environmental Specifications, see page 8.

Relay Contact Ratings - 5069-OX4I

Volts, Max

Continuous

Amps per

Point, Max

Amperes Voltamperes

NEMA ICS

2-125

Make Break Make Break

240V AC

2 A

7.5 A 0.75 A

1800VA 180VA C300

120V AC 15 A 1.5 A

125V DC

0.225 A

(1)

0.22 A

(2)

28VA R150

24V DC 2.0 A

1.16 A

(2)

28VA -

(1) Calculated based on the Rockwell Automation component derating guideline:

90% of rated contact current, that is, 0.25 A at 125V DC.

(2) For DC voltage applications, to determine the make/break ampere rating for relay

contacts, divide 28VA by the applied DC voltage. For example, 28VA/48V DC = 0.58 A.

Rockwell Automation Publication 5069-TD001O-EN-P - May 2024 17

Compact 5000 I/O Modules and EtherNet/IP Adapters

Analog I/O Modules

For information that applies to all of the analog I/O modules, see these tables.

• Wiring and Installation Specifications - Analog I/O Modules

• Certifications - Analog I/O Modules

• Environmental Specifications - Analog I/O Modules

The following analog I/O modules are available.

I/O Type Cat. No. Description Page

Analog input

5069-IF4IH 4-channel isolated current/voltage/HART input module 19

5069-IF8 8-channel current/voltage input module 21

5069-IY4 4-channel current/voltage/RTD/Thermocouple input module

23

5069-IY4K 4-channel conformal coated current/voltage/RTD/Thermocouple input module

Analog output

5069-OF4IH 4-channel isolated current/voltage/HART output module 27

5069-OF4 4-channel current/voltage output module

295069-OF4K 4-channel conformal coated current/voltage output module

5069-OF8 8-channel current/voltage output module

Wiring and Installation Specifications - Analog I/O Modules

Attribute

5069-IF4IH, 5069-IF8, 5069-IY4, 5069-IY4K, 5069-OF4, 5069-OF4K, 5069-OF4IH, 5069-OF8

Channel connections

The wiring diagrams show specific devices that are connected to specific channels. You are not restricted to using only those devices or channels. You can

connect devices to any channel or combination of channels as needed.

Loop devices on a current

loop

Place additional loop devices, for example, strip chart recorders, at either “A” location in a current loop.

SA power

• The analog I/O modules uses DC SA power. You must connect DC power to the device that supplies SA power to the module.

• Use separate external power supplies to provide SA power to the system and to power external devices that are connected to the module.

Ground devices

• The analog I/O modules have two shield terminals. Compact 5000 I/O module RTBs only support one wire per terminal, so you can ground two devices at the

module shield terminals.

• For remaining devices, ground them somewhere else, like the DIN rail via a terminal strip.

If separate power supplies are used to power the additional devices, ground the power supplies at the same ground location.

SA power device list

Connections to an external power supply that provides SA power via the SA power RTB on one of these devices.

• CompactLogix 5380 controller

• Compact GuardLogix 5380 controller

• CompactLogix 5480 controller

• 5069-AENTR EtherNet/IP Adapter

• 5069-FPD field potential distributor

Isolate SA power

If you install modules in a system that uses both AC SA power and DC SA power, you must isolate SA power buses by type with a 5069-FPD field potential distributor.

To create separate SA power buses, complete these steps.

1. Install the modules that use one type of SA power, for example DC, to the right of the adapter or controller. This is the first SA power bus.

2. To create a second SA power bus, install the 5069-FPD field module to the right of these modules.

3. Install the modules that use the other type of SA power, for example AC, to the right of the 5069-FPD module.

Slot width 1

Dimensions (HxWxD) 144.57 x 22 x 105.42 mm (5.69 x 0.87 x 4.15 in.)

Weight, approx 175 g (0.39 lb)

DIN rail Compatible zinc-plated chromate-passivated steel DIN rail. You can use the EN50022 - 35 x 7.5 mm (1.38 x 0.30 in.) DIN rail.

Module keying Electronic keying via programming software

RTB

5069-RTB18-SPRING RTB or 5069-RTB18-SCREW RTB

If at least one thermocouple is connected to the 5069-IY4 or 5069-IY4K modules, you must use the 5069-RTB14CJC-SPRING RTB or 5069-RTB14CJC-SCREW RTB.

NOTE: RTBs do not ship with Compact 5000™ I/O modules, you must order them separately. Order only the RTB type that your system requires.

RTB torque Screw-type RTB only: 0.4 N•m (3.5 lb•in)

RTB keying None

Wire size

0.5…1.5 mm

2

(22…16 AWG) solid or stranded shielded copper wire rated at 105 °C (221 °F) or greater

5069-RTB18-SPRING RTB: 2.9 mm (0.11 in.) max diameter including insulation, single wire connection only.

5069-RTB18-SCREW RTB: 3.5 mm (0.14 in.) max diameter including insulation, single wire connection only.

For the 5069-OW16 module only: Use minimum 18 AWG, 105 °C (221 °F) rated wire for load connections to relay output modules.

Insulation-stripping length

5069-RTB18-SPRING RTB: 10 mm (0.39 in.)

5069-RTB18-SCREW RTB: 12 mm (0.47 in.)

18 Rockwell Automation Publication 5069-TD001O-EN-P - May 2024

Compact 5000 I/O Modules and EtherNet/IP Adapters

Environmental Specifications - Analog I/O Modules

Attribute

5069-IF4IH, 5069-IF8, 5069-IY4, 5069-IY4K, 5069-OF4,

5069-OF4K, 5069-OF4IH, 5069-OF8

Temperature, operating

IEC 60068-2-1

(Test Ad, Operating Cold)

IEC 60068-2-2

(Test Bd, Operating Dry Heat)

IEC 60068-2-14

(Test Nb, Operating Thermal Shock)

0…60 °C (32…140 °F)

Temperature, surrounding

air, max

60 °C (140 °F)

Temperature, nonoperating

IEC 60068-2-1 (Test Ab,

Unpackaged Nonoperating Cold)

IEC 60068-2-2 (Test Bb,

Unpackaged Nonoperating Dry

Heat)

IEC 60068-2-14 (Test Na,

Unpackaged Nonoperating

Thermal Shock)

-40…+85 °C (-40…+185 °F)

Relative humidity

IEC 60068-2-30

(Test Db, Unpackaged Damp Heat)

5…95% noncondensing

Vibration

IEC 60068-2-6 (Test Fc, Operating)

5 g @ 10…500 Hz

Shock, operating

IEC 60068-2-27

(Test Ea, Unpackaged Shock)

30 g

Shock, nonoperating

IEC 60068-2-27

(Test Ea, Unpackaged Shock)

50 g

Emissions IEC 61000-6-4

ESD immunity

IEC 61000-4-2

6 kV contact discharges

8 kV air discharges

Radiated RF immunity

IEC 61000-4-3

10V/m with 1 kHz sine wave 80% AM from 80…6000 MHz

EFT/B immunity

IEC 61000-4-4

±4 kV @ 5 kHz on power ports

±3 kV @ 5 kHz on input ports

Surge transient immunity

IEC 61000-4-5

±1 kV line-line (DM) and ±2 kV line-earth (CM) on power ports

±2 kV line-earth (CM) on shielded input ports

Conducted RF immunity

IEC 61000-4-6

10V rms with 1 kHz sine wave 80% AM from 150 kHz…80 MHz

Voltage variation

IEC 61000-4-29

10 ms interruption on MOD power port

North American temp code T4

UKEX/ATEX temp code T4

IECEx temp code T4

Enclosure type None (open-style)

Certifications - Analog I/O Modules

Certification

5069-IF4IH, 5069-IF8, 5069-IY4, 5069-IY4K, 5069-OF4, 5069-OF4K,

5069-OF4IH, 5069-OF8

c-UL-us

UL Listed Industrial Control Equipment, certified for US and Canada.

See UL File E322657.

UL Listed for Class I, Division 2 Group A,B,C,D Hazardous Locations, certified

for U.S. and Canada. See UL File E334470.

UKCA and CE

UK Statutory Instrument 2016 No. 1091 and European Union 2014/30/EU EMC

Directive, compliant with:

EN 61326-1; Meas./Control/Lab., Industrial Requirements

EN 61000-6-2; Industrial Immunity

EN 61000-6-4; Industrial Emissions

EN 61131-2; Programmable Controllers (Clause 8, Zone A & B)

UK Statutory Instrument 2016 No. 1101 and European Union 2014/35/EU LVD,

compliant with:

EN 61010-2-201; Control Equipment Safety Requirements

UK Statutory Instrument 2012 No. 3032 and European Union 2011/65/EU

RoHS, compliant with:

EN IEC 63000; Technical documentation

RCM

Australian Radiocommunications Act, compliant with

EN 61000-6-4; Industrial Emissions

Ex

UK Statutory Instrument 2016 No. 1107 and European Union 2014/34/EU ATEX

Directive, compliant with:

EN IEC 60079-0; General Requirements

EN IEC 60079-7; Explosive Atmospheres, Protection “e”

II 3 G Ex ec IIC T4 Gc

DEMKO 15 ATEX 1484X and UL22UKEX2379X

IECEx

IECEx System, compliant with:

IEC 60079-0; General Requirements

IEC 60079-7; Explosive Atmospheres, Protection “e”

II 3 G Ex ec IIC T4 Gc

IECEx UL 15.0055X

KC

Korean Registration of Broadcasting and Communications Equipment,

compliant with Article 58-2 of Radio Waves Act, Clause 3

Morocco

Arrêté ministériel n° 6404-15 du 1 er muharram 1437

Arrêté ministériel n° 6404-15 du 29 ramadan 1436

CCC

CNCA-C23-01:2019

CNCA-C23-01:2019 CCC Implementation Rule Explosion-Proof Electrical

Products

CCC: 2020312309000308

See the Product Certification link at rok.auto/certifications

for Declarations of Conformity,

Certificates, and other certification details.

Rockwell Automation Publication 5069-TD001O-EN-P - May 2024 19

Compact 5000 I/O Modules and EtherNet/IP Adapters

5069-IF4IH

4-channel isolated current/voltage/HART input module

The 5069-IF4IH module supports a differential signal and these

device modes.

Current Devices Input Wiring - 5069-IF4IH

Voltage Devices Input Wiring - 5069-IF4IH

Combination of Current and Voltage Devices Input Wiring - 5069-IF4IH

Device Supported Modes

2-wire analog device

4-wire analog device

(1)

Current

Voltage

Combination of current and voltage

The channel configuration in your Logix Designer application project must match the input

device type that is connected to the channel. Select the input type on the Channels tab in

the Module Properties. For example, if a current input device is connected to a channel, the

configuration for the channel must be Input Type = Current.

(1) The 4-wire analog devices are 2-wire current and voltage devices with 2-wire sensor

power connections.

IMPORTANT: This module does not support the use of the voltage input and current input

terminals on the same channel at the same time.

0

7

6

5

4

3

2

1

17

16

15

14

13

12

11

10

9

8

i

Vin 0 +

Vin 0 –

Iin 0 +

Iin 0 –

Vin 1 +

Vin 1 –

Iin 1 +

Iin 1 –

Shield

Shield

Vin 2 +

Vin 2 –

Iin 2 +

Iin 2 –

Vin 3 +

Vin 3 –

Iin 3 +

Iin 3 –

Shield Ground

Shield Ground

–

+

–

+

+

–

A

A

i

A

A

2-wire

Current

Transmitter

+

-

4-wire

Current

Transmitter

–

+

+

-

4-wire

Current

Transmitter

–

+

2-wire

Current

Transmitter

+

–

Power

Supply

Power

Supply

Power

Supply

Power

Supply

0

7

6

5

4

3

2

1

17

16

15

14

13

12

11

10

9

8

Vin 0 +

Vin 0 –

Iin 0 +

Iin 0 –

Vin 1 +

Vin 1 –

Iin 1 +

Iin 1 –

Shield

Shield

Vin 2 +

Vin 2 –

Iin 2 +

Iin 2 –

Vin 3 +

Vin 3 –

Iin 3 +

Iin 3 –

Shield Ground

Shield Ground

+

-

4-wire

Voltage

Transmitter

+

-

4-wire