Making Quality Saw Blades Since 1913

“It has been a real blessing to discover a tool company

that is just as passionate about the blades they make as

I am about the work I do every day.” -Gary Striegler

(Crasman Builders, Inc.)

Ver. 9102G

GENERAL CATALOG

167666-Catalog_v2.indd 3 5/8/19 10:21 AM

1

Table of Contents

TENRYU AMERICA, INC.

TENRYU-Dependable,

Precision Saw Blades

For the finest saw blades in the

world, look no further than TEN-

RYU. TENRYU is known around

the globe as the premier manu-

facturer of quality saw blades.

Satisfied customers attest to the

reliable performance of TENRYU

saw blades worldwide.

TENRYU America Inc. distributes saw

blades in the Americas for TENRYU Saw

Manufacturing Company, Ltd. With five

manufacturing facilities, TENRYU is Japan’s leading

maker of industrial carbide-tipped saw blades.

TENRYU makes over 3,000 different types of carbide

blades for woodworking, metalworking, plastic cutting

and machining other composite materials.

TENRYU blends high-tech scientific techniques with old-

world craftsmanship to ensure that its saw blades are

unsurpassed in design and workmanship.

Designed for Ultimate Performance

Sound design is the foundation of TENRYU’s high quality

saw blades. To produce blades that give the finest cuts,

our designers consider the material that will be cut, the

type of machine that will be used for the cut and the

desired outcome.

Individual Attention Given to

Every Blade

Creating a TENRYU saw blade involves at

least 40 separate processes that are exe-

cuted by the most knowledgeable and

experienced saw blade makers in the

world. While produced in large quantity,

every blade gets individual attention

during production.

Only the Finest

Steel Will Do

TENRYU uses only the very best steel in its quality

blades. Incoming steel lots go through a host of

inspections such as tests for consistency, tensile strength

and hardness. Each lot must fall within a specified

tolerance or it is not accepted. This means TENRYU

suppliers must be especially careful manufacturing the

steel to ensure quality.

Before production begins, every bit of steel is earmarked

for a particular type of blade with specific instructions

for each individual production plan. The blades are

then blueprinted for the entire production run and

coded so computers can track them from point one

to final inspection.

Precision Plate Cutting, Hardening

and Grinding Processes

TENRYU uses laser on high-end blades to incorporate

thin-gap expansion slots. All TENRYU plates are hard-

ened to at least 40 HRC so they can withstand heavy

loads and continue working with excellent results.

All plates are guaranteed to be flat. TENRYU’s proprietary

flattening and surface grinding processes ensure plates

that are distortion free and have uniform thickness.

Hand Craftsmanship Assures

Proper Tensioning

Hammering is a special craft that is learned only

through years of experience. Much like ancient sword-

smiths, the saw doctors at TENRYU’s factory are artisans.

After the saw doctor determines the appropriate ten-

sioning for the blade’s application, he will use special

hammers to level and tension. The plate leaves his hands

flat and true and within tolerance for run-out and balance.

All specifications subject to change without notice.

167666-Catalog_v2.indd 1 5/8/19 10:21 AM

2

Table of Contents

A Word About Safety

To help prevent serious injury,

or even death:

- Read, understand and follow all instructions and warnings in the tool instruction manual as well as

those provided with recommended accessories. This is absolutely essential!

- Keep all guards in place and in proper working order.

- Learn, know and respect all that you can about the causes and preventions of kickback with your saw. If

you don’t know, don’t use the saw.

- Maintain blades and other power tool accessories with care. Keep blades sharp and clean for best and

safest performance.

- Be sure to mount and secure blades on proper and appropriate tools according to the tool’s instruction

manual.

- Always unplug the tool before mounting blades.

- Consider work area environment. Keep all bystanders and fellow workers a safe

distance away.

- Always wear safety goggles or safety glasses with side shields complying with current national standard

and a full face shield when needed. This requirement includes other necessary workers in your work area. They

need to be protected too!

- Be sure to securely clamp workpieces and support evenly. Check frequently to be sure clamps

remain secure.

Warranty Policy

Tenryu America, Inc. guarantees all Tenryu products against defects in material and workmanship. Tenryu America,

Inc. will repair or replace any product that our inspection proves to be defective in material or workmanship.

This warranty does not cover: a) abuse; b) misuse; c) normal wear and tear; d) improper application; e) failure

to mount and secure product properly; f) alterations made to the product by other than Tenryu America, Inc. or

Tenryu Authorized Facilities.

Tenryu America, Inc authorizes no other warranty; written, verbal or implied.

Should you suspect a problem, call 1 (800) 951-SAWS(7297) and request a RGA form with a pre-assigned RGA#.

Then send the product, freight prepaid, to Tenryu America, Inc. at 3601 Hargrave Drive, Hebron, KY 41048.

The RGA form listing the complete description of the cutting application, machine being used, material

description, etc. must be submitted with the product being claimed.

Tenryu will do its very best to conduct a prompt inspection and give a quick resolution to each claim request

submitted properly.

167666-Catalog_v2.indd 2 5/8/19 10:21 AM

3

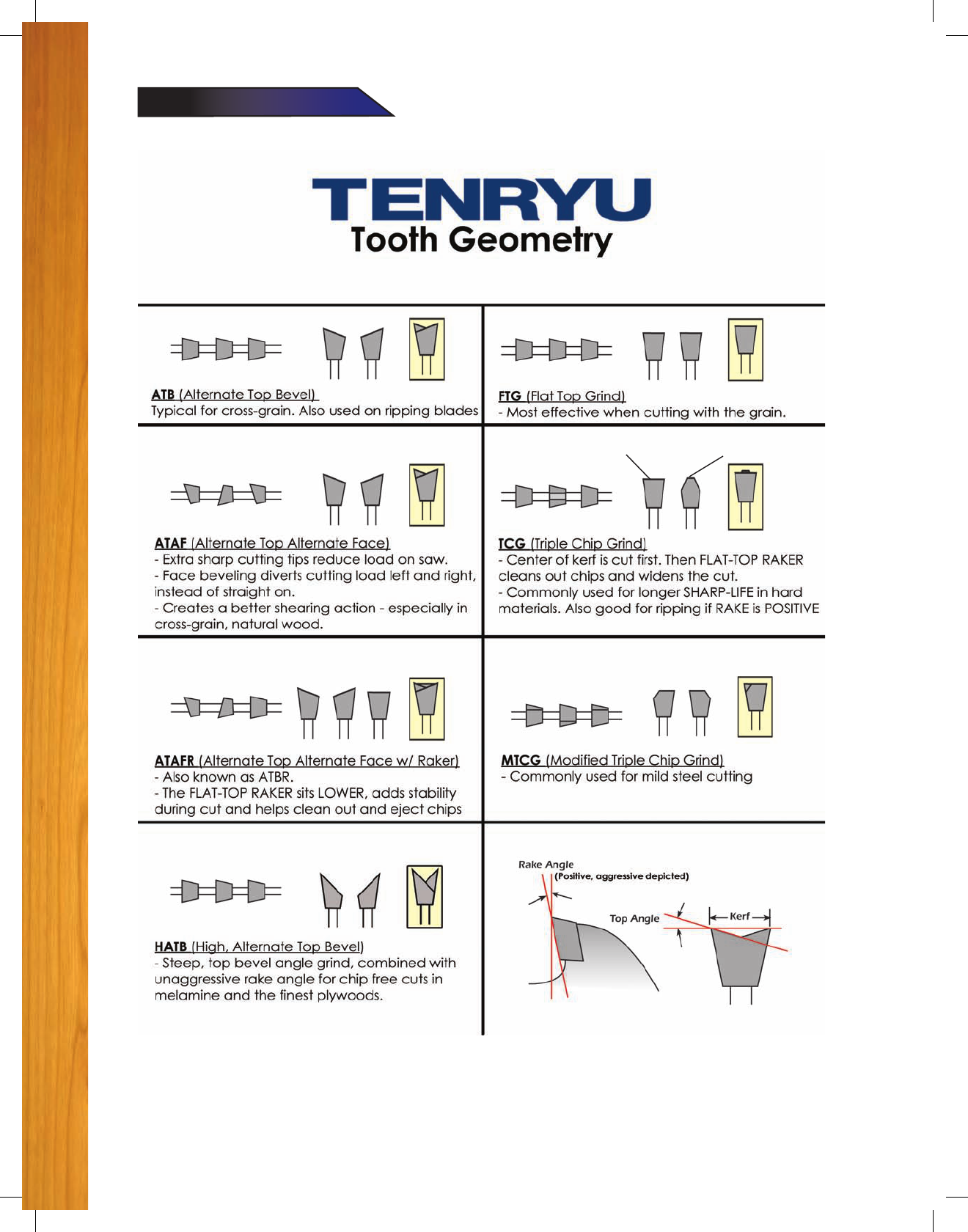

Tooth Geometry

Tooth Geometry

Raker Tooth Chamfer Tooth

(If no face bevel)

167666-Catalog_v2.indd 3 5/8/19 10:21 AM

4

New Items / General Saw Blade Rules

=

=

=

=

New Items

TENRYU is constantly developing new blades to meet the high demands of our

customers. Throughout this catalog you will see many exciting new items.

General Rules Of Thumb

167666-Catalog_v2.indd 4 5/8/19 10:21 AM

Testimonials

5

Testimonials

This is a table saw blade I would

NOT want to be without when I

make my rocking chairs! It saves me

TIME and MONEY! When I install this

blade on my saw it stays for a VERY

long time before I have to remove it

for sharpening. By the time it needs

sharpening the quality of cut has not

degraded. It simply gets harder to

push the wood through the blade.

In the last quarter century I have

cut around 25,000 laminations

for back braces and rockers. The

thickness of these laminations ranges

from 1/16” to 1/8”. Tenryu has

made my task much easier through

the years by providing a clean,

accurate cut that is immediately

ready for glue-up! – Hal Taylor (Hal

Taylor Rocking Chairs)

I have made my living cutting

and fitting joints with wood trim

since 1976, but I have to admit

I don’t think I have ever made a

perfect joint (I have come close

several times). It has always

been my goal to get as close to

perfection as possible.

Pretty early on I realized that

three things have to line up for a

great cut: the skill of the craftsman,

the accuracy of the saw, and the

quality of the blade. If you take

the most skilled carpenter and give

him a substandard saw or a poor

quality blade he will have to work

extremely hard just to get average

results.

The saws that I use have gotten better over the years and I like to think that my skills have increased a

little too, but the quality of my work took a huge step forward when I started using Tenryu blades. When

I rip a board on my table saw it can be hard to tell the difference between a freshly cut edge and one that

has been run over my joiner. Every piece of molding I cut has a mirror smooth edge and blade deflection

is never an issue. I am also amazed at their durability. I have been able to keep the same blade on my

miter saw for as long as 6 months. I really appreciate that they offer a full line high Quality blades for every

saw that I use right down to my 7 ¼ inch circular saw.

I am still driven to exceptional work (hoping for that perfect joint someday) even on the most

challenging projects. It is what keeps me going. It has been a real blessing to discover a tool company that

is just as passionate about the blades they make as I am about the work I do every day. – Gary Striegler

(Craftsman Builders Inc.)

Visit WWW.TENRYU.COM for more information

167666-Catalog_v2.indd 5 5/8/19 10:21 AM

6

Symbol Legend / Table Of Contents

Plunge-cut Saw

P

GS

Radial Arm Saw

Low RPM

Dry Cut Saw

Circular Saw

Table Saw

Miter Saw

Tool Application Symbol Legend

The following symbols are used

throughout this catalog to indicate

the types of tools/machinery that

certain series of blades ar

e

intended

to

be used with to achieve the

highest performance and longevity.

Battery Powered Saw

T

C

R

L

M

B

P

GR

Panel Saw

Angle Grinder

C o n t e n t s

Board-Pro & Board-Pro Plus Series (BP) 8

Coated Silencer Series (SL) 13

Cord-Free Series for Wood (CF) 7

Diamond-Pro Series (DA) 22

FESTOOL KAPEX® Series 14

Gold Medal Dado (GMD) 16

Gold Medal Series (GM) 15

Industrial Blade Series (IW, IL, IS) 18

Industrial Blade Series for Sliding Table Saw (IL, IW) 19

Mel-Pro Series (ML) 20

Miter-Pro & Miter-Pro Series Plus (MP) 17

Panel-Pro Series (PP) 10

Plastic Cutter Series (PC) 21

Plunge-Cut Saw Blade Series (PS) 14

Power Tool Series (PT) for Miter & Slide Miter Saw 10

Power Tool Series (PT) for Portables & Small Table Saws 9

Pro Series for Plastic (PRP) 21

Pro Series for Solid Surface (PRS) 12

Pro Series for Wood Material (PR) 11

Rapid-Cut Series (RS) 12

Silencer Series (SL) 13

Tenryu Super Diamond Series (TSD) 22

Ultimate Trim Saw Blade Series (SL) 13

Visit WWW.TENRYU.COM for more information

167666-Catalog_v2.indd 6 5/8/19 10:21 AM

7

Cord-Free Series

First and MOST COMPLETE LINE of premium saw blades made especially for cordless saws.

The growth in the cordless saw industry has created a void with the cord-free series when it

comes to accessory blades. TENRYU has filled the void.

EACH BLADE FEATURES:

• Ultra-thin, perfectly tensioned steel plates for true run. This saves precious battery power and life.

• Precision honed, high-grade carbide for easy, smooth cuts and long life.

• Tooth configurations to meet specific cutting material and thickness applications.

CORD-FREE SERIES for WOOD MATERIALS*

Cord-Free Series

B

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

CF-08520 3-3/8” 20 15mm ATB 10 0.039 2240 For cutting wood with 3-3/8” cordless saws. Makita, or B&D.

CF-13530W 5-3/8” 30 10mm ATAF 20 0.047 3200 For general purpose with 5-3/8” DeWALT cordless saw.

CF-14036W 5-1/2” 36 10mm ATAF 15 0.063 4200 For cutting wood with 5-1/2” cordless saws. Craftsman or Ryobi.

CF-15218W 6” 18 1/2” ATAF 15 0.063 2600 For ripping wood with 6” Porter Cable trim saw.

CF-15236W 6” 36 1/2” ATAF 15 0.063 2600 For general purpose with 6” Porter Cable trim saw.

CF-16516WB 6-1/2” 16 5/8” ATAF 20 0.059 3900 For ripping wood with 6-1/2” cordless saws. Bulk packaged.

CF-16524W 6-1/2” 24 5/8” ATAF 20 0.059 3900 For general purpose with 6-1/2” cordless saws. Many manufacturers.

CF-16524WB 6-1/2” 24 5/8” ATAF 20 0.059 3900 For general purpose with 6-1/2” cordless saws. Bulk packaged.

CF-16540W 6-1/2” 40 5/8” ATAF 20 0.059 3900 For nish cutting with 6-1/2” cordless saws. Many manufacturers.

CF-16540WB 6-1/2” 40 5/8” ATAF 20 0.059 3900 For nish cutting with 6-1/2” cordless saws. Bulk packaged.

*See also: Power Tool Series……(Page 9)

Silencer Series…………(Page 13)

Ultimate Trim Saw Blade Series….(Page 14)

Steel Cutting and Aluminum Cutting saw blades for cordless saws are

listed in the Metal Cutting Saw Blade Catalog section on the other

side of this catalog.

Visit WWW.TENRYU.COM for more information

167666-Catalog_v2.indd 7 5/8/19 10:22 AM

8

Board-Pro Plus Series / Board-Pro Series

BOARD –PRO PLUS SERIES - Poly-Crystalline Diamond Faced Tips

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

BP-16504 6-1/2” 4 5/8”KO FTG 12 0.091 9250 Single/Stacked sheets up to 5 sheets

BP-18505 7-1/4” 5 5/8”KO FTG 12 0.091 8300 Single/Stacked sheets up to 5 sheets

BP-25506 10” 6 5/8” FTG 8 0.098 5870 Single/Stacked sheets up to 5 sheets

BP-30508 12” 8 1” FTG 8 0.098 5000 Single/Stacked sheets up to 5 sheets

Board Pro Plus & Board Pro Series

The BEST CHOICE for

LONG LASTING PERFORMANCE

when cutting Fiber Cement Board.

FIber Cement Board is a very abrasive material that

wears down normal carbide very quickly. The TENRYU

BOARD-PRO PLUS incorporates PCD (Poly-Crystalline

Diamond) tips for longer life.

C

M

EACH BOARD-PRO PLUS BLADE FEATURES:

• Perfectly-tensioned, hardened tool-steel plates for flat, true run.

• Select quality PCD (Poly-Crystalline Diamond) faced tips for longer life.

• Extra long blade life.

• LOWER COST PER CUT!

• LESS DUST than traditional blades produce.

• Designed for cutting multiple stacked sheets.

Framing Blades - Power Tool Series

PT-18524AM

PT-18524V

PT-18524P

GenerAl PurPose

Fast & smooth

WeT or Pressure TreATed

high PerFormance

*See page 9 for blade specifications & applications

*

C

EACH BOARD-PRO BLADE FEATURES:

• Perfectly-tensioned, hardened tool-steel plates for flat, true run.

• Select quality carbide grade.

• TENRYU quality craftsmanship.

• Economically priced.

• LESS DUST than traditional blades produce.

BOARD-PRO SERIES – Special Grade Carbide Tipped (For Single Sheet Cutting only)

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

BP-18524 7-1/4” 24 5/8”KO ATAF 10 0.075 8300 Fast cuts on 1-2 sheet thickness

PT-18540CB 7-1/4” 40 5/8”KO ATAF 12 0.073 8300 Great for trimming on single sheet

BP-30540 12” 40 1” ATAF 5 0.091 5000 Great for trimming on single sheet, only straight cuts (Not for bevelling)

Visit WWW.TENRYU.COM for more information

NEW

NEW

NEW

Heavy Metal/Heavy Metal Plus Series

Line Items

Coated Silencer Series

167666-Catalog_v2.indd 8 5/8/19 10:22 AM

Power Tool Series

Power Tool Series

Power Tool Series for the Contractor

Exceptional features and superior quality, Thin Kerf

TENRYU’S comprehensive line of blades for portable and stationary power tools. More variety, better quality

and greater value. Sizes range from 4” to 12” for most types of applications. The TENRYU PT SERIES

goes on to include thin kerf wood cutting blades designed especially for smooth cuts on miter and slide-

compound. See below.

BLADE FEATURES:

• Fully hardened, expertly tensioned tool steel bodies absorb impact, remain flat and true, and resist

excess heat build-up.

• High-grade, C-3, fine-grain tungsten carbide tips resist erosion for extended blade life.

• Aggressive rake angles for maximum cutting speed and efficiency.

• Each tip is precision honed on all four exposed surfaces. This minimizes micro-chipping along the

sharp edge of the tip and results in a sharper, longer-lasting edge.

• Thin kerf for less waste and lighter cutting performance (reduced feed pressure).

• Inserted tooth design on some models greatly increases the body-to-tip braze area for greater support

and tip strength.

• Expansion slots and/or variable pitch gullets keep blade true under stressful work loads.

• Can be resharpened for extended blade life.

POWER TOOL SERIES - Primarily for Portable Saws and Table Saws.

C

T

M

B

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

PT-10006-1 4” 6 22mm FTG 20 0.157 11000 For very clean and accurate biscuit slots

PT-10006-2 4” 6 22mm ATAFR 25/-15 0.157 11000 For exceptionally clean and smooth biscuit slots

PT-10024 4” 24 20mm ATAF 18 0.055 11000 Woodworking with Makita 5044KB, or 4200NH

PT-11036 4-3/8” 36 20mm ATAF 15 0.063 13800

For ne trim woodworking with Makita trim saw

PT-11536 4-1/2” 36 3/8” ATAF 15 0.063 13200 For ne trim woodworking with Porter Cable trim saw

PT-14036 5-1/2” 36 5/8”,1/2” ATAF 15 0.063 10800 For ne trim woodworking with Makita trim saw

PT-15236 6” 36 1/2” ATAF 15 0.063 9500 For ne trim woodworking with Porter Cable trim saw

PT-16524 6-1/2” 24 5/8”KO ATB 20 0.079 9250 General woodworking with 6-1/2” corded, or cordless circular saws

PT-16524-T 6-1/2” 24 5/8”KO ATAF 20 0.059 9250 Thin-kerf general woodworking with 6-1/2” corded, or cordless circular saws

PT-16540 6-1/2” 40 5/8”KO ATB 20 0.079 9250 Finish woodworking with 6-1/2” corded, or cordless circular saws

PT-16540CR 6-1/2” 40 BEVEL ATB 18 0.063 5300 For Crain jamb saw : model #810(H), not for No. 812H, 820

PT-16540-T 6-1/2” 40 5/8”KO ATB 18 0.063 9250 Thin-kerf nish woodworking with 6-1/2” corded, or cordless circular saws

PT-18516B 7-1/4” 16 5/8”KO ATB 27 0.073 8300 Our fastest framing and ripping saw blade with INSERTED teeth

PT-18524AM 7-1/4” 24 5/8”KO ATB 20 0.073 8300 The AMIGO 24 Tooth contractor blade. Fast and long cutting life.

PT-18524P 7-1/4” 24 5/8”KO ATB 20 0.073 8300 Great for wet, or pressure treated lumber. Green coating.

PT-18524V 7-1/4” 24 5/8”KO ATB 20 0.073 8300 The unique VARIABLE PITCH design for wood, pressure treated, or composite decking.

PT-18540 7-1/4” 40 5/8”KO ATB 27 0.073 8300 Unique INSERT tooth design cross cutting blade.

PT-18540B 7-1/4” 40 5/8”KO ATAF 18 0.063 8300 Ultra thin-kerf for nish cross cutting. Bulk packaged.

PT-18540-T 7-1/4” 40 5/8”KO ATB 18 0.063 8300 Ultra thin-kerf for nish cross/rip cutting.

PT-20360 8” 60 5/8”KO ATAF 5 0.087 7300 Smooth nish woodworking with 8” saws. Also good for vertical panel saws

PT-21018 8-1/4” 18 5/8”KO ATB 25 0.075 7300 Fast ripping with circular, table, or chop saws. INSERTED tooth design.

PT-21040 8-1/4” 40 5/8”KO ATB 15 0.079 7300 General woodworking with 8-1/4” saws.

PT-21060 8-1/4” 60 5/8”KO ATAF 12 0.079 7300 Finish woodworking with 8-1/4” saws.

PT-21624 8-1/2” 24 5/8” ATB 15 0.087 7000 Fast cutting. Good for heavy stock.

PT-21640 8-1/2” 40 5/8” ATB 15 0.087 7000 General woodworking

PT-26036 10-1/4” 36 5/8”KO ATAF 20 0.079 5870 Ripping wood with Big Foot saw

9

Visit WWW.TENRYU.COM for more information

167666-Catalog_v2.indd 9 5/8/19 10:22 AM

10

Power Tool Series / Panel-Pro Series

Visit WWW.TENRYU.COM for more information

The “PT” Series blades for miter, and slide miter saws,

range in sizes from 8-1/2” for the popular Hitachi

through 12” diameters. 14” blades for older saws can

be found on page 11 in our Pro Series for Wood. 15”

miter saw blades are available in our Miter-Pro Series

on page 17.

NOTE: This series may also be used for crosscutting

applications on table saws.

EACH BLADE FEATURES:

• Thin kerf design is easier on miter saw motors and brakes.

• Fully hardened, expertly tensioned tool steel bodies.

• Fine grain tungsten carbide tips with fine grit honing for keen edges.

• Excellent price/value

POWER TOOL SERIES - For Miter or Slide Miter Saws

For Miter and Slide Miter Saws

Power Tool Series

M

T

Excellent for long lasting, precise cuts in wood, wood composites, and laminated materials on panel saws.

Panel saws are often used to cut large sheets of “difficult” materials like MDF, melamine or particle board. These

materials are laden with chemicals and adhesives which attack the carbide causing corrosion of the cutting edge.

The Panel-Pro blades come equipped with our best anti-corrosive micro-grain carbide. That, plus our super-flat,

perfectly tensioned plate adds up to very precise, long lasting performance on your panel saw!

For cutting aluminum materials on panel saws, see our Alumi-Cut Series blades. For cutting Solid Surface Materials, see

our Pro Series for Solid Surface.

Try these blades even without the scoring saw- you’ll love the results!

EACH BLADE FEATURES:

• Fully-hardened, expertly-tensioned tool steel bodies for true and accurate cuts.

• High-grade, extra hard, wear-resistant carbide tips for long life.

• Fine grit honing of carbide edges for clean, smooth cuts.

• Resin bond-filled expansion slots for reduced vibration and quieter cutting.

Panel-Pro Series

Panel-Pro Series

P

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

PT-21660-1 8-1/2” 60 5/8” KO ATAF 5 0.079 7000 Finish cross cutting on wood.

PT-21680 8-1/2” 80 5/8” ATAF 10 0.087 7000 Super smooth woodworking

PT-23040 9” 40 5/8” ATAF 5 0.087 6400 General woodworking 9” miter, or table saws

PT-25540 10” 40 5/8” ATB 0 0.083 5870 General purpose woodworking . Good for heavy stock.

PT-25550 10” 50 5/8” ATAF 15 0.091 5870 Great value nish cutting saw blade. INSERTED tooth design.

PT-25560 10” 60 5/8” ATB 0 0.083 5870 General purpose woodworking

PT-25560D 10” 60 5/8” TCG 10 0.087 5870 General purpose woodworking. TCG grind.

PT-25572A 10” 72 5/8” ATB 15 0.098 5870 Clean cutting on wood

PT-25590 10” 90 5/8” ATAF 10 0.091 5870 Super smooth woodworking

PT-305100 12” 100 1” ATAF 5 0.094 5000 Super smooth woodworking

PT-30560 12” 60 1” ATAF 3 0.094 5000 General purpose woodworking . Good for heavy stock.

PT-30580 12” 80 1” ATAF 5 0.094 5000 General purpose woodworking

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

PP-20360AB 8” 60 5/8” ATAFR 0 0.110 7300 For 8” vertical panel saws (Milwaukee, Safety Speedcut)

PP-22060AB 220mm 60 30mm* ATAFR 0 0.110 6900 For European panel saws (220mm)

PP-30075AB 300mm 75 30mm* ATAFR 0 0.110 5100 For European vertical panel saws, or sliding table saws (300mm)

*with pin-drive holes

167666-Catalog_v2.indd 10 5/8/19 10:22 AM

Pro Series for Wood

Visit WWW.TENRYU.COM for more information

11

STANDARD BLADE

TENRYU PRO SERIES

Pro Series for Wood

T

SEE PAGE 18 for Extra Heavy-duty Blade choices

TENRYU’S superior quality line for professional craftsmen

Laser cut, press tempered, individually hammer tensioned, and chrome-plated bodies bring

the cutting edge to the workpiece with unparalleled precision. Fine grain carbide tips are

given the tooth configuration to do the job right. Pro Series blades are also made to handle

non-ferrous metal cutting, plastics, or solid surface materials. These blades are made to

satisfy the most demanding craftsmen.

EACH BLADE FEATURES:

• Fully-hardened, expertly-tensioned tool steel bodies for true and accurate cuts.

• High-grade, fine grain, C-3 wear-resistant carbide tips for long life.

• Fine grit honing of carbide edge for clean, smooth cuts.

• Resin bond-filled expansion slots act as built in dampeners- keeping your cuts quiet and the

saw’s plate vibration-free!

“ The cuts were so quiet and effortless that

I thought I had forgotten to raise the blade.”

Reduced vibration results in extended life of

of tip edge. Note comparison of standard

blade to TENRYU blade.

(After cutting 4.3 miles of particle board!)

Pro Series for Wood Materials

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

PR-25560CBN 10” 60 5/8” ATB 20 0.110 5870 Fast and clean table saw blade. ATB grind.

PR-25560D 10” 60 5/8” TCG 10 0.110 5870 Fast and clean table saw blade. TCG grind.

PR-25580CBN 10” 80 5/8” ATB 20 0.118 5870 Clean, nish cross-cutting table saw blade. ATB grind.

PR-25580D 10” 80 5/8” TCG 10 0.118 5870 Clean, nish cross-cutting table saw blade. TCG grind.

PR-255100AB 10” 100 5/8” ATAFR 15 0.118 5870 For use in veneer plywood or thinner stock with table saws.

PR-30560CBN 12” 60 1” ATB 20 0.118 5000 General purpose table saw blade. Combination. Good for thick stock.

PR-30580CBN 12” 80 1” ATB 20 0.118 5000 General purpose cross-cutting table saw blade. Good for thick stock.

PR-305100AB 12” 100 1” ATAFR 15 0.118 5000 For use in veneer plywood or thinner stock with table saws.

PR-35580AB 14” 80 1” ATAFR 15 0.118 4300 General purpose table saw blade. Combination. Good for thick stock.

PR-355100AB 14” 100 1” ATAFR 15 0.118 4300 For use in veneer plywood or thinner stock with table saws.

PR-405100CBN 16” 100 1” ATB 20 0.126 3690 For use in veneer plywood or thinner stock with table saws.

167666-Catalog_v2.indd 11 5/8/19 10:22 AM

Pro Series for Solid Surface

TENRYU’S Premium Heavy Duty, Industrial, Multi-Purpose Blades

We offer an entire line of industrial duty “work horse” blades that cover the 10 to 16 inch diameter range.

These blades are all meant to be used on shop tools such as table saws. In addition, many models can be used

on more specialized machinery with arbor hole adjustments. Each blade has a large carbide tip following the

European tradition.

Value is key here. These blades are priced very competitively. The small shop and corporate giant alike will

appreciate getting quality industrial blades at attractive prices.

EACH BLADE FEATURES:

• Individually hand-hammered, fully heat hardened steel plates for flat, true, wobble-free operation.

• Aggressive grind angles for easy performance in heavy-duty jobs. Honing carried out at 400 grit to

limit microchipping and produce a very keen edge.

• Large, high-grade carbide tips selected for long life in woodworking applications.

• Ample side clearance provides for air flow between carbide and workpiece - limits likelihood of burning

even on heavy rips. This also prevents premature dulling.

Rapid-Cut Series

Pro Series for Solid Surface / Rapid Cut Series

12

Rapid Cut Series

T

T

M

EACH BLADE FEATURES:

• Laser cut, fully-hardened tool steel plates for industrial use.

• Individually hand-tensioned plates for true, accurate cuts.

• Built-in dampening system to minimize vibration and reduce noise.

• Fine-grain, C-3, premium-grade carbide tips for smoother cuts and longer life.

Pro Series for Solid Surface (PRS) Materials

*with pin-drive holes

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

PRS-18540 7-1/4” 40 5/8” KO TCG -5 0.094 5800 For clean, easy cuts with circular saws.

PRS-20360 8” 60 5/8” TCG -5 0.094 7300 For 8” vertical panel saws (Milwaukee, Safety Speedcut)

PRS-22064 220mm 64 30mm* TCG

-5 0.102 6900 For European panel saws (220mm)

PRS-25560 10” 60 5/8” TCG -5 0.102 5870 General purpose with Miter, or Table saws

PRS-25580 10” 80 5/8” TCG -5 0.102 5870 Finish cutting. Good for thinner stock.

PRS-30080 300mm 80 30mm* TCG -5 0.110 5100 For European vertical panel saws, or sliding table saws (300mm)

PRS-305100 12” 100 1” TCG -5 0.110 5000 Finish cutting. Good for thinner stock.

PRS-30580 12” 80 1” TCG -5 0.110 5000 General purpose with Miter, or Table saws

PRS-355100 14” 100 1” TCG -5 0.126 4300 General purpose with Miter, or Table saws

PRS-405120 16” 120 1” TCG -5 0.134 3690 General purpose with Miter, or Table saws

PRS-455120 18” 120 1” TCG -5 0.134 3400 General purpose with Miter, or Table saws

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

RS-25524CBN 10” 24 5/8” ATB 20 0.126 5870 Fast ripping with table saws. Great value.

RS-25524-U 10” 24 5/8” ATB 20 0.079 5870 Ultra thin-kerf(.079”) ripping blade for Table saws.

RS-25536CBN 10” 36 5/8” ATB 20 0.126 5870 Fast cutting general purpose

RS-25540 10” 40 5/8” ATAF 15 0.118 5870 General purpose. Economically priced. Great value.

RS-25540-U 10” 40 5/8” ATAF 20 0.079 5870 Ultra thin-kerf(.079”) combination blade for Table saws.

RS-25548CBN 10” 48 5/8” ATB 20 0.126 5870 General purpose combination

RS-25550 10” 50 5/8” ATBR 15 0.126 5870 TENRYU’s original planer combination

RS-25550-2 10” 50 5/8” ATBR 15 0.126 5870 Quiet planer combination with resin lled laser slots.

RS-25560 10” 60 5/8” ATAF 10 0.118 5870 General purpose cross-cutting. Economically priced. ATAF grind.

RS-25560D 10” 60 5/8” TCG 10 0.126 5870 General purpose cross-cutting. Economically priced. TCG grind.

RS-30524CBN 12” 24 1” ATB 20 0.134 5000 Fast ripping with table saws. Great value.

RS-30536CBN 12” 36 1” ATB 20 0.134 5000 Fast cutting general purpose

RS-30548CBN 12” 48 1” ATB 20 0.134 5000 General purpose combination

RS-30560 12” 60 1” ATBR 15 0.134 5000 TENRYU’s original planer combination

RS-35524CBN 14” 24 1” ATB 20 0.142 4300 Fast ripping with table saws. Great value.

RS-35536CBN 14” 36 1” ATB 20 0.142 4300 Fast cutting general purpose

RS-35548CBN 14” 48 1” ATB 20 0.142 4300 General purpose combination

RS-40536CBN 16” 36 1” ATB 20 0.134 3690 Fast cutting general purpose

RS-40560CB 16” 60 1” ATAF 15 0.126 3690 Cross-cutting for semi-smooth cut quality

Visit WWW.TENRYU.COM for more information

SEE PAGE 18 for Extra Heavy-duty Blade choices

167666-Catalog_v2.indd 12 5/8/19 10:22 AM

Silencer/Coated Silencer/Ultimate Trim Saw Blade Series

13

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

SL-16552 6-1/2” 52 5/8”KO ATAF 18 0.063 9250 Extra smooth cross-cutting with corded, or cordless saws

SL-18552 7-1/4” 52 5/8”KO ATAF 18 0.063 8300 Extra smooth cross-cutting with corded, or cordless saws

SL-21660 8-1/2” 60 5/8” ATAF 5 0.079 7000 Extra smooth cross-cutting with Miter saws.

SL-25540 10” 40 5/8” ATAF 5 0.098 5870 General purpose. Fast cutting. Good for thick stock.

SL-25560 10” 60 5/8” ATAF 5 0.098 5870 General purpose woodworking.

SL-25572 10” 72 5/8” ATAF 10 0.110 5870 Our signature 10” Silencer blade for all purpose

SL-25580 10” 80 5/8” ATAF 5 0.091 5870 Finish cross cutting on wood.

SL-26072 260mm 72 30mm ATAF 10 0.110 5870 Our signature Silencer blade for general purpose woodworking

SL-30540 12” 40 1” ATAF 5 0.098 5000 General purpose. Fast cutting. Good for thick stock.

SL-30560 12” 60 1” ATAF 5 0.098 5000 General purpose woodworking.

SL-30580 12” 80 1” ATAF 5 0.091 5000 Finish cross cutting on wood.

SL-305100 12” 100 1” ATAF 5 0.091 5000 Our signature 12” Silencer blade for super clean cuts

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

SL-25572C 10” 72 5/8” ATAF 10 0.110 5870 Our signature 10” Silencer blade for all purpose with coating

SL-25580C 10” 80 5/8” ATAF 5 0.110 5870 Finish cross cutting on wood.

SL-30580C 12” 80 1” ATAF 5 0.106 5000 Finish cross cutting on wood.

SL-305100C 12” 100 1” ATAF 5 0.106 5000 Our signature 12” Silencer blade for super clean cuts with coating

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

SL-25550C 10” 50 5/8” ATBR 15 0.126 5870 Super smooth and quiet planer combination blade. Full kerf (.125”)

SL-25550TC 10” 50 5/8” ATBR 15 0.110 5870 Super smooth and quiet planer combination blade. Intermediate kerf (.110”)

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

SL-11040C 4-3/8” 40 20mm ATAF 15 0.063 13800 For Makita trim saw

SL-11542C 4-1/2” 42 3/8” ATAF 15 0.063 13200 For Porter Cable trim saw

SL-14042C 5-1/2” 42 5/8”,1/2” ATAF 15 0.063 10800 For Makita trim saw

SL-15248C 6” 48 1/2” ATAF 15 0.063 9500 For Porter Cable trim saw

SL-16552C 6-1/2” 52 5/8”KO ATAF 18 0.063 9250 For 6-1/2” corded, or cordless trim saws

SL-18560C 7-1/4” 60 5/8”KO ATAF 15 0.063 8300 For Circular saws

NEW

NEW

NEW

Heavy Metal/Heavy Metal Plus Series

Line Items

Coated Silencer Series

Visit WWW.TENRYU.COM for more information

Silencer Series

C

M

EACH BLADE FEATURES:

• Vibration dampening system featuring patented TENRYU resin bond filled laser cut body slots.

• Meticulous, hand hammer plate tensioning for a flatter blade and truer cuts

Smoother Cuts Cleaner Edges Quieter Cutting Longer Sharp-Life

*Unique ATAF Shear face grind for Fast and Long Lasting Cuts

*Dampened Laser Cut Plate for Less Vibration

*Great for Sliding Compound Miter Saw

Coated Silencer Series

Coated Silencer Series for Table Saws

•

Full-Kerf (.126”) or Intermediate-Kerf (.110”), The choice is yours

•

Unique Intermediate-Kerf (.110”) for easier feed, less material waste,

and great for under-powered table saws(portable)

Coated Silencer Series for Miter/Slide Miter Saws

•

Anti-Friction PTFE coating for easier feeding and less binding

•

Hardened slick surface for preventing pitch build-up

•

Silencer series’ signature anti-noise and anti-vibration plate with resin filled slots

*Silencer body : Laser cut, resin filled slots for

less noise and less vibration

*PTFE coated plate : Reduces pitch build up and

lowers resistance

*Great for finish carpentry with corded/cordless saws

C

Ultimate Trim Saw Blade Series

167666-Catalog_v2.indd 13 5/8/19 10:22 AM

14

Plunge-Cut Saw Blade/FESTOOL KAPEX® Series

Visit WWW.TENRYU.COM for more information

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

PSW-16012CBD2 160mm 12 20mm ATB 20 0.094 9250 Wood (Fast ripping)

PSW-16028CBD2 160mm 28 20mm ATB 15 0.087 9250 Wood (Combination)

PSW-16048AB2 160mm 48 20mm ATAFR 10 0.087 9250 Wood, or Veneer Plywood (Cross cutting, nishing)

PSW-16052CB2TK 160mm 52 20mm ATAF 15 0.063 9250 Wood (Cross cutting, nishing) Ultra thin kerf package, NOT for REQ model.

PSL-16048ABM2 160mm 48 20mm ATAFR -5 0.094 9250 Laminate (Single, or double sided)

PSL-16048D2 160mm 48 20mm TCG 5 0.094 9250 MDF, Solid Surface, Flooring, or Laminate (Single sided)

PSA-16056D2 160mm 56 20mm TCG -3 0.094 9250 Non-ferrous metal

PSW-21018CBD3 210mm 18 30mm ATB 20 0.094 7300 Wood (Fast ripping)

PSW-21036CBD3 210mm 36 30mm ATB 15 0.087 7300 Wood (Combination)

PSW-21054AB3 210mm 54 30mm ATAFR 10 0.087 7300 Wood, or Veneer Plywood (Cross cutting, nishing)

PSL-21052D3 210mm 52 30mm TCG 5 0.094 7300 MDF, Solid Surface, Flooring, or Laminate(Single sided)

PSA-21068D3 210mm 68 30mm TCG -3 0.094 7300 Non-ferrous metal

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

IW-26080AB3 260mm 80 30mm ATBR -5 0.096 5870 Ultimate trim cutting blade for professional carpentry. Great for small/thin/tall molding

MP-26080AB 260mm 80 30mm ATAFR -3 0.110 5870 Finish/Trim cutting with less knife marks for smooth surface

SL-26072 260mm 72 30mm ATAF 10 0.110 5870 Our signature Silencer blade for general purpose woodworking

TENRYU proudly carries quality saw blades

for plunge cut saws. These blades are

suitable for:

• The FESTOOL

®

TS55 & TS75 machines

• and others.

5 year R&D work and study for ultimate

plunge-cut saw blades in various applications.

•Resin filled laser cut slots to reduce

cutting noise and to reduce vibration

•PTFE coated plate to

reduce pitch

build-up and to lower resistance

•Select grade of carbide tips for in-

dustrial quality jobs

•ATAF shear face grind for splinter-

free cross cuts

P

GS

Plunge-cut Saw Blade Series

FESTOOL KAPEX® Series

M

Choose the right blade

for your KAPEX

®

• Unique tooth geometries provide

optimum cutting results over OEM

offerings

• Resin-filled laser cut slots reduce cutting

noise and vibration

• Diameter and arbor specific for perfect fit

167666-Catalog_v2.indd 14 5/8/19 10:22 AM

Gold Medal Series

15

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

GM-25540-2 10” 40 5/8” ATB 20 0.125 5870 The highest quality combination blade. Good for SAWSTOP table saws

Visit WWW.TENRYU.COM for more information

Gold Medal Series

T

GOLD MEDAL

This is the top of the line choice for the serious craftsman who wants

one superior table saw blade for most all woodworking.

Saw plate run-out less than .002” for flat true run. Built-in dampening system reduces

vibration, making cuts quieter and more precise. Performs smooth, easy crosscuts and rips.

Even does a great job on veneer plywood.

Carbide tip material is an extra hard, C-4 and super fine grain with corrosion inhibitors to

give the keenest edge and longest sharp-life.

EACH BLADE FEATURES:

• Fully-hardened, expertly-tensioned tool steel body for true and accurate cuts,

meticulously hand hammer tensioned.

• A new grade of extra hard carbide resists both abrasive and chemical wear better

than standard grades for longer life.

• Resin bond-filled expansion slots to absorb any vibration and reduce cutting noise.

• TENRYU’S fine grit honing ensures mirror finish on carbide for the keenest possible

edges and a super clean cut.

Gold Medal Series

“Rated as TOP TOOL by WOOD MAGAZINE (Dec./Jan. 2007/2008 issue)

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

GM-25540 10” 40 5/8” ATB 20 0.111 5870 The highest quality combination blade. Original intermediate kerf.(.111”)

GM-30560

12” 60 1” ATB 20 0.118 5000 The highest quality combination blade.

GM-35560 14” 60 1” ATB 20 0.126 4300 The highest quality combination blade.

Full Kerf Gold Medal

Due to customer demand, we added a Full-Kerf (.125”) version of our award-winning

Gold Medal. This premium combination blade is ideal for use on SawStop or other riving knife

equipped table saws.

“These are easily the best blades I have

ever had the pleasure of using. Thanks to the

new thicker kerf, I am happy to say a Tenryu

Gold Medal blade has found a permanent

home in my tablesaw.“ Marc Spagnuolo,

The Wood Whisperer,

www.TheWoodWhisperer.com “

167666-Catalog_v2.indd 15 5/8/19 10:22 AM

Gold Medal Dado

16

...”Its C4 carbide teeth are thicker and taller

than the Forrest blade, so you may just get

a few more trips into the sharpening service

with this blade before it needs a fresh set of

teeth.”...

T

Gold Medal Dado Set

Superior Cutting Performance

You know our Gold Medal Series to be the best all around blades made anywhere.

The Gold Medal Dado Set will only add to TENRYU’S reputation as the brand of choice

for the finest woodworking. This set produces super-clean dado edges with an

astoundingly flat bottom surface in wood materials and even in melamine.

BLADE AND CHIPPER FEATURES:

• Fully heat-treated saw plates for superior endurance under heavy load.

• Individually hand hammer-tensioned for flat and true runs.

• Fine-grit honing of ALL sides of teeth for sharp, easy cutting action and long life.

• Super fine-grain carbide grade for longer life and easier resharpening.

• Probably the lightest feeding dado you will ever experience!

Gold Medal Dado Set- GMD-20340

GROOVE OPTIONS: 1/4”, 5/16”, 3/8”, 7/16”, 1/2”, 9/16”, 5/8”, 11/16”, 3/4”, 13/16”

NOTE: The part number for the complete set is GMD-20340. Should a user require individual

pieces as numbered above, it will require a special order and will be quoted at the time of

inquiry.*Outer cutters cannot be used individually. The actual kerf of each is approx. 1/8”.

Placed together, the result is exactly ¼”.

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

GMD-20340 8” 40 5/8” ATBR 0 0.813 5870 Premium quality dado set. For 1/4” - 13/16” width dadoing.

Visit WWW.TENRYU.COM for more information

167666-Catalog_v2.indd 16 5/8/19 10:22 AM

17

Miter-Pro Series / Miter Pro Plus Series

Visit WWW.TENRYU.COM for more information

TENRYU responds to customer demand! We have a line of blades specially designed for high

performance, smoothest cuts and heavier duty applications on miter saws and slide-miter saws.

These are our “Cadillac/Mercedes” grade miter saw blades.

TENRYU’S proven, super-true, laser-cut, hand tensioned steel plate with patented, resin bond-filled

expansion slots ensures smooth, accurate and quiet cuts.

Specially designed, top-quality, micro-grain carbide tips, honed to a precision edge with 600 grit

diamond wheels cut clean and easy.

Rake angle design prevents lifting of workpiece but does not make your saw overwork. The result

is a safer, chip-free and smooth cut.

EACH BLADE FEATURES:

• Fully-hardened, expertly-tensioned tool steel bodies for true and accurate cuts.

• High-grade, fine grain carbide tips for long life.

• Super-fine grit honing of carbide edge for clean, smooth cuts.

• Additional resin bond-filled expansion slots for even quieter cutting.

Miter-Pro Series

All the features of our Miter-Pro series PLUS added technological improvements to make them better and heavier-duty than ever.

• Finest and smoothest cuts ever on your miter saw.

• Best suited blade for the latest Slide Miter Saws as well as traditional Miter Saws.

• Negative rake angle tooth design (-3 degree) - For finer cuts in thin or brittle materials.

• Reduced tendency to grab materials being cut.

• Additional, Resin-Filled Silencing Slots in plate eliminate troublesome vibration for smoother cuts,

reduced noise and longer sharp-life.

TENRYU’s ultimate

woodworking blade

for

Miter and Slide Miter saws

Miter-Pro Series

M

SEE PAGE 18 for Extra Heavy-duty Blade choices

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

MP-25560CB 10” 60 5/8” ATAF 0 0.110 5870 General purpose. Good for thicker stock.

MP-25580CB 10” 80 5/8” ATAF 0 0.118 5870 Finish/smooth cutting

MP-305100CB 12” 100 1” ATAF 0 0.118 5000 Finish/smooth cutting

MP-305100CB2 12” 100 5/8” ATAF 0 0.118 5000 Finish/smooth cutting with Double miter saws

MP-30560CB 12” 60 1” ATAF 0 0.118 5000 General purpose. Good for thicker stock.

MP-30580CB 12” 80 1” ATAF 0 0.118 5000 General purpose. Smooth cutting.

MP-380100CB 15” 100 1” ATAF 0 0.126 4020 Finish/smooth cutting

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

MP-25560AB 10” 60 5/8” ATAFR -3 0.110 5870 A great choice for fast and smooth cutting on thicker wood

MP-25580AB 10” 80 5/8” ATAFR -3 0.110 5870 Smooth cutting. Wide variety material thickness. Great for trim carpentry.

MP-255100AB 10” 100 5/8” ATAFR -3 0.110 5870 Super smooth cutting. Especially designed for thinner stock.

MP-26080AB 260mm 80 30mm ATAFR -3 0.110 5870 Finish/Trim cutting with less knife marks for smooth surface

MP-30560AB 12” 60 1” ATAFR -3 0.118 5000 A great choice for fast and smooth cutting on thicker wood

MP-30580AB 12” 80 1” ATAFR -3 0.118 5000 General purpose. Smooth cutting.

MP-305100AB 12” 100 1” ATAFR -3 0.118 5000 Smooth cutting. Wide variety material thickness. Great for trim carpentry.

MP-305100AB2 12” 100 5/8” ATAFR -3 0.118 5000 Smooth cutting. Wide variety material thickness. Great for trim carpentry.

M

P-355100AB2 14” 100 5/8” ATAFR -3 0.118 4700 Smooth cutting. Wide variety material thickness. Great for trim carpentry.

MP-380100AB 15” 100 1” ATAFR -3 0.126 4020 Finish/smooth cutting

Miter-Pro Plus Series

M

NEW

NEW

NEW

Heavy Metal/Heavy Metal Plus Series

Line Items

Coated Silencer Series

167666-Catalog_v2.indd 17 5/8/19 10:22 AM

18

Industrial Blade Series

Visit WWW.TENRYU.COM for more information

INDUSTRIAL BLADE SERIES for MITER SAW – Wood (Positive rake, thin kerf, ATAF Grind)

INDUSTRIAL BLADE SERIES for RADIAL ARM SAW or MITER SAW – Wood (Negative rake, ATBR Grind)

INDUSTRIAL BLADE SERIES for MITER SAW or TABLE SAW – Solid Surface

INDUSTRIAL BLADE SERIES for TABLE SAW – Wood

INDUSTRIAL BLADE SERIES for TABLE SAW – Melamine

INDUSTRIAL BLADE SERIES for TABLE SAW – Wood (Glue Line Ripping)

INDUSTRIAL BLADE SERIES for STRAIGHT LINE RIP SAW – Wood

NEW

NEW

NEW

Heavy Metal/Heavy Metal Plus Series

Line Items

Coated Silencer Series

NEW

NEW

NEW

Heavy Metal/Heavy Metal Plus Series

Line Items

Coated Silencer Series

NEW

NEW

NEW

Heavy Metal/Heavy Metal Plus Series

Line Items

Coated Silencer Series

NEW

NEW

NEW

Heavy Metal/Heavy Metal Plus Series

Line Items

Coated Silencer Series

Industrial Blade Series

T

R

M

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

IW-25540CB1 10” 40 5/8” ATAF 5 0.091 5870 Fast cutting with Miter saws

IW-25560CB1 10” 60 5/8” ATAF 5 0.091 5870 General purpose woodworking with Miter saws

IW-25580CB1 10” 80 5/8” ATAF 5 0.091 5870 Finish cutting with Miter saws

IW-30540CB2 12” 40 1” ATAF 5 0.094 5000 Fast cutting with Miter saws

IW-30560CB2 12” 60 1” ATAF 5 0.094 5000 General purpose woodworking with Miter saws

IW-30580CB2 12” 80 1” ATAF 5 0.094 5000 Finish cutting with Miter saws

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

IW-25540AB1 10” 40 5/8” ATBR -3 0.110 5870 Combination. General woodworking with Radial arm saws

IW-25580AB1 10” 80 5/8” ATBR -5 0.096 5870 Finish cutting. Great for trim carpentry

IW-26080AB3 260mm 80 30mm ATBR -5 0.096 5870 Ultimate trim cutting blade for professional carpentry.

Great for small/thin/tall molding

IW-30550AB2 12” 50 1” ATBR -3 0.110 5000 Combination. General woodworking with Radial arm saws

IW-30580AB2 12” 80 1” ATBR -5 0.104 5000 General purpose. Smooth cutting.

IW-30590AB1A 12” 90 5/8” ATBR -3 0.118 5000 Finish miter cutting with less chipping

IW-305100AB2 12” 100 1” ATBR -5 0.104 5000 Finish cutting. Great for trim carpentry.

IW-35560AB2 14” 60 1” ATBR -3 0.118 4300 Combination. General woodworking with Radial arm saws

IW-355110AB1 14” 110 5/8” ATBR -3 0.118 4300 Finish miter cutting with less chipping

IW-38060AB2 15” 60 1” ATBR -3 0.118 4020 Combination. General woodworking with Radial arm saws

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

IS-25560D1 10” 60 5/8” TCG -5 0.102 5870 General purpose solid surface cutting with Table, or Miter saw

IS-30580D2 12” 80 1” TCG -5 0.110 5000 General purpose solid surface cutting with Table, or Miter saw

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

IW-25524CBD1 10” 24 5/8” ATB 20 0.126 5870 For general ripping

IW-25540CBD1 10” 40 5/8” ATB 10 0.118 5870 General purpose combination with Table saws. ATB grind.

IW-25540D1 10” 40 5/8” TCG 10 0.118 5870 General purpose combination with Table saws, Also good for Nylon, or UHMW

IW-25560CBD1 10” 60 5/8” ATB 10 0.118 5870 Finish woodworking with Table saws, ATB grind.

IW-25560D1 10” 60 5/8” TCG 10 0.118 5870 Finish woodworking with Table saws, TCG grind.

IW-30528CBD2 12” 28 1” ATB 20 0.126 5000 For general ripping

IW-35532CBD2 14” 32 1” ATB 20 0.138 4300 For general ripping

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

IL-25580H1 10” 80 5/8” HATB -5 0.118 5870 Hi-ATB grind for chip-free cutting of double sided low-pressure laminate

IL-305100H2 12” 100 1” HATB -5 0.118 5000 Hi-ATB grind for chip-free cutting of double sided low-pressure laminate

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

IW-25530D1 10” 30 5/8” TCG 20 0.142 5870 Glue-line quality ripping (Mainly for up to 3/4” thick wooden board)

IW-30536D2 12” 36 1” TCG 20 0.157 5000 Glue-line quality ripping (Mainly for up to 3/4” thick wooden board)

IW-35540D2 14” 40 1” TCG 20 0.157 4300 Glue-line quality ripping (Mainly for up to 3/4” thick wooden board)

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

IW-30550AB2A 12” 50 1” ATAFR 20 0.118 5000 Ripping with Straight line rip saws (Not for other equipment)

Tenryu’s European industrial quality line for heavy duty applications.

EACH BLADE FEATURES:

• Select grade of carbide tip for better performance.

• Large European style tips.

• Heavy, European plate style resists deflection during cutting.

• Resin bond, laser slots to absorb and eliminate vibration to produce a cleaner, quieter, more efficient cut

• Excellent blade life.

167666-Catalog_v2.indd 18 5/8/19 10:22 AM

Industrial Blade Series

19

Visit WWW.TENRYU.COM for more information

INDUSTRIAL BLADE SERIES for SLIDING TABLE SAWS/VERTICAL PANEL SAWS

Ripping

Cross Cuts

Combination (Rip or Cross-cut)

Composite Man-made board materials including plywood

Tenryu’s European industrial quality line for heavy duty applications.

EACH BLADE FEATURES:

• Select grade of carbide tip for better performance.

• Large European style tips.

• Heavy, European plate style resists deflection during cutting.

• Resin bond, laser slots to absorb and eliminate vibration to produce a cleaner, quieter, more

efficient cut

• Excellent blade life.

Industrial Blade Series

T

P

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

IW-30028CBD3 300mm 28 30mm ATB 25 0.128 5100 General ripping

IW-35032CBD3 350mm 32 30mm ATB 25 0.136 4300 General ripping

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

IW-25080AB3 250mm 80 30mm ATAFR 10 0.128 5870 Cross/nish cutting on veneer plywood ATAFR grind

IW-300100AB3 300mm 100 30mm ATAFR 10 0.128 5100 Cross/nish cutting on veneer plywood ATAFR grind

IW-350100AB3 350mm 100 30mm ATAFR 10 0.136 4300 Cross/nish cutting on veneer plywood ATAFR grind

IW-25080ABD3 250mm 80 30mm ATBR 15 0.128 5870 Cross/nish cutting on solid wood ATBR grind

IW-300100ABD3 300mm 100 30mm ATBR 15 0.128 5100 Cross/nish cutting on solid wood ATBR grind

IW-350100ABD3 350mm 100 30mm ATBR 15 0.136 4300 Cross/nish cutting on solid wood ATBR grind

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

IW-25040CBD3 250mm 40 30mm ATB

20 0.128 5870 General purpose combination with Table saws. ATB grind.

IW-30050CBD3 300mm 50 30mm ATB 20 0.128 5100 General purpose combination with Table saws. ATB grind.

IW-35060CBD3 350mm 60 30mm ATB

20 0.136 4300 General purpose combination with Table saws. ATB grind.

Double sided low pressure laminate (Melamine) with No scoring blade use

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

IL-25080H3 250mm 80 30mm HATB -5 0.118 5870 Chip-free cutting on double sided low-pressure laminate without scoring blade

IL-300100H3 300mm 100 30mm HATB -5 0.118 5100 Chip-free cutting on double sided low-pressure laminate without scoring blade

IL-350100H3 350mm 100 30mm HATB -5 0.118 4300 Chip-free cutting on double sided low-pressure laminate without scoring blade

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

IW-25080D3 250mm 80 30mm TCG 10 0.128 5870 For composite materials, plywood, etc. TCG grind. With/Without scoring blade

IW-300100D3 300mm 100 30mm TCG 10 0.128 5100 For composite materials, plywood, etc. TCG grind. With/Without scoring blade

IW-350100D3 350mm 100 30mm TCG 10 0.136 4300 For composite materials, plywood, etc. TCG grind. With/Without scoring blade

This series is designed for fitting metric-sized saws (250mm-350mm dia) with

dedicated 30mm arbors, and the following pin-hole patterns:

(# of holes)-(Hole diameter)-(Bolt Circle)

2-7.0mm-42.0mm

2-9.0mm-46.0mm

2-10.0mm-60.0mm

167666-Catalog_v2.indd 19 5/8/19 10:22 AM

20

Mel-Pro Series

The Ultimate Single-Sided Laminate(Low Pressure/High Pressure)

and Veneer-Faced Plywood Cutting Blade!

The Mel-Pro Series is a complete line of blades that solve problems associated with cutting laminated wood

products. Additionally, veneer-faced plywood can be cut without splintering at more reasonable feed speeds than

in the past.

FINER CUTS- Precision ground carbide teeth set on hand-tensioned tool steel bodies produce finer cuts without

chipping and “bottom-side blowout”.

QUIETER- Patented resin bond-filled expansion slots effectively absorb vibration and reduce noise.

LONGER LIFE- High-grade, extra-hard, micro-grain, anti-corrosive carbide teeth fight both chemical and abrasive

wear to remain sharp longer. There are a lot of blades on the market that can cut melamine but only the

TENRYU Mel-Pro can cut it chip free, quieter, easier and longer.

Numerous requests for a better melamine blade prompted us to spend over a year of research and development

to bring you the world’s most advanced melamine cutting blade. The Mel-Pro features a fully hardened, expertly

tensioned tool steel body that absorbs impact, remains flat and true, and resists excess heat buildup. The Mel-

Pro’s exclusive, red bond, resin filled expansion slots absorb vibration, reduce heat and permit the blade to run

quieter than any other brand. The thin-kerf, mirror-like grind on super hard, specially designed carbide tips allow

for lighter cuts and reduce friction heat buildup. The bottom line is your bottom line will look better when you

reduce scrap, reduce sharpening costs and reduce noise in your shop with Mel-Pro blades.

The ORIGINAL Mel-Pro Series

Hi-ATB MelAMine(Single/DouBle SiDeD low PreSSure lAMinATe)

EACH BLADE FEATURES:

• Hi-ATB design with negative (-5 )rake angle tooth geometry - NO TEAR OUT!

• Traditional full-kerf, “European Style” blade design

• C-4 hardness, super fine grain, anti-corrosive carbide tips for the keenest edges and extended sharp life.

Premium, Industrial Hi-ATB Series Features:

• Specially developed, top-grade, super fine grain carbide tip.

• Additional, “resin-filled, laser cut body slots” suceed in vibration dampening to an even greater extent

• Exhaustive, hand-hammer plate tensioning assures truer and smoother cuts.

• Longer Lasting than our competitors’.

Though Mel-Pro Blades are typically used on table saws, they also perform spectacularly well on Miter and Slide Miter Saws.

Mel-Pro Series

T

M

SEE PAGE 18 for Extra Heavy-duty Blade choices

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

ML-25580AB 10” 80 5/8” ATAFR 0 0.118 5870 For laminate material, single sided laminate board, or veneer plywood

ML-255100AB 10” 100 5/8” ATAFR 0 0.118 5870 For thin laminate board, or veneer plywood

ML-305100AB 12” 100 1” ATAFR 0 0.126 5000 For laminate material, single sided laminate board, or veneer plywood

ML-305120AB 12” 120 1” ATAFR 0 0.126 5000 For thin laminate board, or veneer plywood

ML-355120AB 14” 120 1” ATAFR 0 0.126 4300 For laminate material, single sided laminate board, or veneer plywood

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

ML-21060H 8-1/4” 60 5/8” HATB -5 0.118 7300 Premium Hi-ATB saw blade for 8-1/4” table saws

ML-25580H 10” 80 5/8” HATB -5 0.118 5870 Chip-free cutting of double sided low-pressure laminate

ML-255100H 10” 100 5/8” HATB -5 0.118 5870 Especially good for thinner stock

ML-30580H 12” 80 1” HATB -5 0.126 5000 Chip-free cutting of double sided low-pressure laminate

ML-305100H 12” 100 1” HATB -5 0.126 4700 Especially good for thinner stock

ML-355100H 14” 100 1” HATB -5 0.126 4700 Chip-free cutting of double sided low-pressure laminate

Visit WWW.TENRYU.COM for more information

167666-Catalog_v2.indd 20 5/8/19 10:22 AM

Plastic Cutter Series/Pro Series for Plastics

21

TENRYU’S best value for quality

cuts in a wide variety of plastics.

Thin Kerf!

Excellent Cuts!

Pro Series for Plastics

Plastic Cutter Series

T

M

B

T

M

The Plastic Cutter series offers true quality, variety, and affordability. Designed for general purpose

cutting applications, the Plastic Cutter blades will perform very well in a wide variety of plastic materials.

Cutting plastics with the wrong blade results in chipping of brittle materials and/or melting of the

cut edge. TENRYU Plastic Cutter blades are manufactured to strict tolerances to reduce chipping.

In addition, the “no melt” grind pattern on the carbide teeth helps keep heat build-up down and

prevents melting. Smooth, clean and melt-free cuts in PVC, acrylics, and other sheet plastics are

made possible.

EACH BLADE FEATURES:

• Individually hammer tensioned steel plates for true run.

• Specially selected grade of carbide for excellent work in plastic.

• TENRYU’S super fine honing leaves a mirror-like finish on the carbide for clean and melt-free cuts.

Plastic Cutter Series

TENRYU’S superior quality line for professional craftsmen

Laser cut, press-tempered, individually tensioned, and chrome-plated

bodies bring the cutting edge to the workpiece with unparalleled precision.

Fine grain carbide tips are given the tooth configuration to do the job right .

EACH BLADE FEATURES:

• Fully-hardened, expertly-tensioned tool steel bodies for true and accurate cuts.

• High-grade, fine-grain, C-4, wear-resistant carbide tips for long life.

• Resin bond-filled expansion slots act as built in dampeners - giving quiet cuts and

reduced chipping!

Pro Series for Plastics

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

PC-10036 4” 36 20mm ATAF 10 0.055 11000 For Makita 5044KB, or 4200NH

PC-18560CB 7-1/4” 60 5/8”KO ATAF 5 0.079 8300 General purpose plastic cutting with circular saws

PC-25580CB 10” 80 5/8” ATAF 5 0.102 5870 For wide variety plastic cutting with 10” saws

PC-305100CB 12” 100 1” ATAF 5 0.110 5000 For wide variety plastic cutting with 12” saws

PC-355100CB 14” 100 1” ATAF 5 0.118 4300 For wide variety plastic cutting with 14” saws

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

PRP-25580CB 10” 80 5/8” ATAF 5 0.125 5870 General plastic cutting with Table, or Miter saws.

PRP-255120AB3 10” 120 5/8” ATAFR 0 0.079 5870 Chip-free cutting on thin sheet acrylic, or extrusion.

PRP-305100CB 12” 100 1” ATAF 5 0.134 5000 General plastic cutting with Table, or Miter saws.

PRP-355100CB 14” 100 1” ATAF 5 0.134 4300 General plastic cutting with Table, or Miter saws.

Visit WWW.TENRYU.COM for more information

167666-Catalog_v2.indd 21 5/8/19 10:22 AM

Diamond-Pro Series

High quality DIAMOND

grit blades for general

construction applications

using saws or grinders.

C

Diamond-Pro Series

C

GS

Tenryu Super Diamond Series / Diamond-Pro Series

MODEL NO. DIA TYPE ARBOR MAX RPM APPLICATION

DA-185S-SL 7-1/4” SEGMENT 5/8”KO 8300 General construction purpose

ALWAYS WEAR EYE PROTECTION that meets ANSI Z87.1 requirements and PROPERLY FUNCTIONING BLADE/WHEEL GUARD

TSD was originally developed to cut and grind cast-iron

and ductile iron materials. Through further refinement it was

discovered that fast, efficient cutting and grinding of a multitude

of other materials is possible. That includes limited applications in

mild steel, brick, granite, marble and other natural stones, ceramic materials,

solid-surface materials, fiber reinforced plastics and a variety of masonry materials.

TSD (TENRYU SUPER DIAMOND) - Depressed Center, Cup Wheel

TSD (TENRYU SUPER DIAMOND) - Cutoff Blades

MODEL NO. DIA TYPE ARBOR MAX RPM APPLICATION

TSD-105C 4” CUP 7/8” mm 14500 Great for fast caulk removal

MODEL NO. DIA TYPE ARBOR MAX RPM APPLICATION

TSD-180D 7” DIAMOND ABRASIVE 5/8” KO 8300 For circular saws

TSD-305D 12” DIAMOND ABRASIVE 1” 6300 For gas-powered equipment

TSD-305D2 12” DIAMOND ABRASIVE 20 mm 6300 For gas-powered equipment

TSD-355D 14” DIAMOND ABRASIVE 1” 5400 For gas-powered equipment

TSD-355D2 14” DIAMOND ABRASIVE 20 mm 5400 For gas-powered equipment

TSD Series

Visit WWW.TENRYU.COM for more information

22

167666-Catalog_v2.indd 22 5/8/19 10:22 AM

Heavy Metal Plus Series

Heavy Metal Plus Series

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

HMC-18036BW 7” 36 20mm MTCG 0 0.073 4000 1/8” - 1/4” WALL THICKNESS

HMC-18536BW 7-1/4” 36 5/8”KO MTCG 0 0.073 4800 1/8” - 1/4” WALL THICKNESS

HMC-20342DM 8” 42 5/8”KO TCG -5 0.065 4300 1/8” - 1/4” WALL THICKNESS

HMC-20342BW 8” 42 5/8”KO MTCG 0 0.073 4300 1/8” or THICKER STOCK

HMC-23048BW 9” 48 1” MTCG 0 0.073 3000 1/8” or THICKER STOCK

HMC-30554DX 12” 54 1” MTCG 2 0.087 2000 1/8” - 1/2” WALL THICKNESS

HMC-35566DX 14” 66 1” MTCG 2 0.087 1800 1/8” - 1/2” WALL THICKNESS

Specially Engineered Alloy teeth provide exceptional cut-life

and lowest cost per cut in the most demanding applications

The Heavy Metal Plus Series is an evolution of the Heavy Metal

in that it features the same super thin-kerf and grinds as the Heavy

Metal Series, but features our specially engineered alloy cutting tips

to further extend cut-life in heavy load applications.

Visit WWW.TENRYU.COM for more information

12

Heavy Metal Plus Series

C

L

Please note all safety instructions before use and adhere to instructions for maximum RPM speeds.

ALWAYS WEAR EYE PROTECTION that meets ANSI Z87.1 requirements and PROPERLY FUNCTIONING UPPER and LOWER GUARDS

Heavy Metal

“We cut a wide variety of angle, flat bar, round bar, and tubing up to 4” square

and I have tried all of the blades out there for our 14” Dry Cut saw. The Tenryu

Heavy Metal exceeds the performance of any other blade we have ever used, and

provides the lowest cost per cut which adds to our bottom line.”

Hank Moss

Owner

HMW Fabrication

Heavy Metal Plus

“We manufacture custom trailers, and frequently cut 1 ¼” flat bar and 3”x6”

rectangular tubing. We recently began using the Tenryu Heavy Metal Plus blade

and saw an immediate increase in cut life of four times what we had been

experiencing with the carbide-tipped Tenryu Heavy Metal blade. We will be using

these blades from now on!”

Rick Davis

Lead Fabricator

Bohnenkamp Whitewater Customs

167666-Catalog_v2.indd 12 5/8/19 10:23 AM

Heavy Metal Series

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

HM-18036D 7” 36 20mm TCG 2 0.067 4000 1/8” - 1/4” WALL THICKNESS

HM-18536D 7-1/4” 36 5/8”KO TCG 2 0.067 4800 1/8” - 1/4” WALL THICKNESS

HM-20342D 8” 42 5/8”KO TCG 2 0.067 4300 1/8” or THICKER STOCK

HM-23048D 9” 48 1” TCG 2 0.067 3000 1/8” or THICKER STOCK

HM-30554DX 12” 54 1” MTCG 2 0.087 2000 1/8” - 1/2” WALL THICKNESS

HM-35566DX 14” 66 1” MTCG 2 0.087 1800 1/8” - 1/2” WALL THICKNESS

11

Visit WWW.TENRYU.COM for more information

Heavy Metal Series

Please note all safety instructions before use and adhere to instructions for maximum RPM speeds.

ALWAYS WEAR EYE PROTECTION that meets ANSI Z87.1 requirements and PROPERLY FUNCTIONING UPPER and LOWER GUARDS

Heavy Metal Series

C

L

These Blades ROCK! Take Your Pick! Two Great

Options Specifically Designed for Heavy Gauge

Ferrous Metal Cutting.

Our newest offering for your Metalworkers! Both the

HEAVY METAL and the HEAVY METAL PLUS are designed for

users seeking affordability, quick cutting, and long cut-life;

especially in heavier mild steel profiles and plate. Common end-users are:

•

Industrial staircases, railings, mezzanines, platforms, grating, trailers, strut, etc.

•

Rigging, oil field services equipment

•

Plant and Equipment Maintenance and Repair (MRO)

Thin-Kerf design coupled with lower tooth count for effortless cutting of thick-wall mild steel

(7” and 7-1/4” blades : 1/8”-1/4”, 8” and 9” blades : 1/8” – 1/2”, 12” and 14” blades : 1/8” – 1/2”)

Good for Metal cutting saws (Evolution, SteelMax, MK Morse, Milwaukee, JEPSON, Makita,

DeWALT, Worm-Drive circular saws, or other make)

HEAVY METAL

The Heavy Metal series feature select C-6 grade micro-grain carbide and affords excellent

value, and long cut-life. The Heavy Metal Series incorporates an industry-leading super

thin-kerf design; triple-chip grind (TCG) and modified triple-chip grind (MTCG) tooth

geometries, and is well suited for job-site and shop applications.

167666-Catalog_v2.indd 11 5/8/19 10:23 AM

Cord-Free Series for Stainless Steel / Steel-Pro

®

for

Stainless Series

Visit WWW.TENRYU.COM for more information

CORD-FREE SERIES for STAINLESS STEEL

STEEL-PRO® for STAINLESS SERIES

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

SPS-18064 7” 64 20mm MTCG 0 0.063 4000

Best for sheet stainless no thicker than 12 gauge. Not suitable for heavy stock

SPS-20372 8” 72 5/8” MTCG 0 0.071 4300 Best for sheet stainless no thicker than 12 gauge. Not suitable for heavy stock

SPS-23080 9” 80 1” MTCG 0 0.071 3000 Best for sheet stainless no thicker than 12 gauge. Not suitable for heavy stock

SPS-30578 12” 78 1” MTCG 10 0.087 1700 1/8”-1/4” wall thickness, angles, solid, etc.

SPS-30578A 12” 78 1” MTCG 0 0.087 1700 Up to 1/4” wall thickness of Tubing(Round or Square) and Channels

SPS-35590 14” 90 1” MTCG 10 0.087 1700 1/8”-1/4” wall thickness, angles, solid, etc.

SPS-35590A 14” 90 1” MTCG 0 0.087 1700 Up to 1/4” wall thickness of Tubing(Round or Square) and Channels

SPS-355120 14” 120 1” MATB -3 0.079 1700 For thin gauge (14-16 gauge) stock, Great for tubing

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

CF-13556S 5-3/8” 56 20mm MTCG 0 0.043 3700

Best for sheet stainless no thicker than 12 gauge. Not suitable for heavy stock

10

Now it is possible to cut stainless steel with greater efficiency on your

low RPM metal-cutting saw

The Steel-Pro® for Stainless Series is the result of nearly two years of intensive product testing.

Never before has cutting stainless steel been so easy and cost effective. The TENRYU Steel-Pro®

for Stainless blades allow you to cut a wide variety of

stainless steel materials with:

• GREATLY IMPROVED CUTTING SPEED

• LESS BURR ON EDGES (resulting in tremendous time savings)

• NO SCORCHING OF THE STAINLESS

• REDUCED SPARKING

• FEWER BLADE CHANGES

EACH BLADE FEATURES:

• Unique tooth design and geometry for smoother and easier cuts.

• Resin bond-filled laser expansion slots for reduced vibration.

• Grade of carbide for longer cutting life in stainless steel.

These blades, when used for the proper application, will save time and money.

Steel-Pro for STAINLESS Series

L

USAGE REQUIREMENTS: ALL BLADES

USE ONLY LOW RPM DRY-CUT SAWS ONLY

303 & 304 STAINLESS ONLY

HIGHLY RECOMMENDABLE TO USE LUBRICANT

OR WAX

CLAMP MATERIAL SECURELY TO BASE

PART NO. SPS-30578 and SPS-35590

MATERIAL WALL THICKNESS (1/8” to 1/4”)

NOT DESIGNED FOR TUBING

PART NO. SPS-30578A AND SPS-35590A

MATERIAL WALL THICKNESS UP TO 1/4”

GREAT FOR TUBING

PART NO. SPS-355120

MATERIAL WALL THICKNESS (VERY THIN STOCK

14-16 GAUGE)

GREAT FOR TUBING

PART NO. CF13556S, SPS-18064, SPS-20372

and SPS-23080

MATERIAL THICKNESS 14 – 16 GAUGE, NO

THICKER THAN 12 GAUGE

GREAT FOR FLAT STOCK

NEW

NEW

NEW

Heavy Metal/Heavy Metal Plus Series

Line Items

Coated Silencer Series

NEW

NEW

NEW

Heavy Metal/Heavy Metal Plus Series

Line Items

Coated Silencer Series

NEW

NEW

NEW

Heavy Metal/Heavy Metal Plus Series

Line Items

Coated Silencer Series

NEW

NEW

NEW

Heavy Metal/Heavy Metal Plus Series

Line Items

Coated Silencer Series

Please note all safety instructions before use and adhere to instructions for maximum RPM speeds.

NEW

NEW

NEW

Heavy Metal/Heavy Metal Plus Series

Line Items

Coated Silencer Series

NEW

NEW

NEW

Heavy Metal/Heavy Metal Plus Series

Line Items

Coated Silencer Series

167666-Catalog_v2.indd 10 5/8/19 10:23 AM

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

PRF-18538DS 7-1/4” 38 5/8”KO TCG 0 0.079 5800 Good for 1/8” to 1/4” wall thickness.

PRF-18548DS 7-1/4” 48 5/8”KO TCG 0 0.079 5800 General purpose. Up to 1/8” wall thickness.

PRF-25550DS 10” 50 1”, 5/8” TCG 0 0.091 2500 General purpose. Up to 1/8” wall thickness. For 10” DRY CUTTERS ONLY

PRF-30560DS 12” 60 1” TCG 0 0.094 2000 General purpose. Up to 3/8” wall thickness. For 12” Dry cutters (JEPSON, Makita, etc)

PRF-30580BWS 12” 80 1” MTCG -5 0.091 2000 Thin gauge wall material cutting (20 gauge to 1/16”) with Dry cutters

PRF-35572DS 14” 72 1” TCG 0 0.094 1800 General purpose. Up to 3/8” wall thickness. For 14” dry cutters

PRF-35590BWS 14” 90 1” MTCG -5 0.091 1800 Thin gauge wall material cutting (20 gauge to 1/16”). For dry cutters

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

PRF-18536BWK 7-1/4” 36 5/8”KO MTCG 0 0.079 5800 Good for 1/8” to 1/4” wall thickness.

PRF-18548BWK 7-1/4” 48 5/8”KO MTCG 0 0.079 5800 New signature steel cutting blade for mechanical construction. Up to 1/8” wall thickness

PRF-20348BWK 8” 48 5/8”KO MTCG 0 0.087 4300 All purpose steel cutting blade for mechanical construction. Up to 1/8” wall thickness

PRF-21048BWK 8-1/4” 48 5/8”KO MTCG 0 0.087 5800 All purpose steel cutting blade for mechanical construction. Up to 1/8” thickness

PRF-23048BWK 9” 48 1” MTCG 0 0.087 3700 All purpose steel cutting blade for mechanical construction. Up to 1/8” wall thickness

PRF-30560DK 12” 60 1” TCG 0 0.098 2000 General purpose. Up to 3/8” wall thickness. For 12” Dry cutters(JEPSON, Makita, etc)

PRF-35572DK 14” 72 1” TCG 0 0.098 1700 General purpose. Up to 3/8” wall thickness. For 14” Dry cutters

Steel-Pro® Select Series

Steel-Pro

®

STABILIZER Series / Steel-Pro

®

SELECT Series

Visit WWW.TENRYU.COM for more information

Steel-Pro STABILIZER Series

C

L

Please note all safety instructions before use and adhere to instructions for maximum RPM speeds.

ALWAYS WEAR EYE PROTECTION that meets ANSI Z87.1 requirements and PROPERLY FUNCTIONING UPPER and LOWER GUARDS

9

TENRYU establishes an even higher standard

of steel-cutting excellence! TENRYU has

raised the bar once again in the portable

saw, steel-cutting industry!

Virtually all test monitors recognized better longevity of the

blade. This “STABILIZER” technology stabilizes the blade in

the cut with much less vibration during operation. Cleaner cuts,

longer life and a more comfortable feeling are great benefits of “STABILIZER”,

making it more “User-friendly”.

TENRYU blades do not require blade plate stabilizers, as is commonly known in the market. In fact, the

patent pending design technology or our “STABILIZER” blade eliminates any need for a blade stabilizer and

produces an even more effective job!

EACH BLADE FEATURES:

•”STABILIZER” plate (Pat, Pend.) improves the cutting performance

•

Better straightness of cut

•

Cleaner cuts

•

Longer cutting life

•

Reduced Burring

•

Reduced scattering of steel debris

•

Less vibration

The Steel-Pro® Select is TENRYU’S 2nd generation of

mild steel cutting carbide tipped saw blades…Quieter!

These blades are designed to cut mild steel as STEEL-PRO® blades do, but cut

quieter than STEEL-PRO® and last longer as well.

EACH BLADE FEATURES:

• Exclusive, two-ply plate design for self dampening and low noise operation.

• Tough C-6 carbide for impact resistance and long cutting life.

• Inserted teeth with chip limiting steel support for added durability and safety.

Steel-Pro SELECT Series

®

C

L

167666-Catalog_v2.indd 9 5/8/19 10:23 AM

MODEL NO. DIA TEETH ARBOR GRIND RAKE KERF MAX RPM APPLICATION

PRF-16048 6-1/4” 48 5/8”KO MTCG

0 0.079 5300 For Corded, or Cordless saws. Up to 1/8” wall thickness.

PRF-18538BW 7-1/4” 38 5/8”KO ATB

0 0.079 5800 Good for 1/8” to 1/4” wall thickness.

PRF-18548BW 7-1/4” 48 5/8”KO ATB

0 0.079 5800

Our signature STEEL-PRO blade for mechanical construction. Up to 1/8” wall thickness

PRF-18548CBWD 7-1/4”

48 5/8”KO

MATB 0 0.073 5800 For mechanical construction. Up to 1/8” wall thickness

PRF-18556CB 7-1/4” 56 5/8”KO ATAF -10 0.071 5800 More number of teeth for cutting thin sheet steel (Flat stock only)

PRF-18570CBN 7-1/4” 70 5/8”KO ATB -10 0.069 5800 For very thin sheet steel (Flat stock only)

PRF-20348CBN 8” 48 5/8”KO MTCG 0 0.087 4300 General purpose. Up to 1/8” wall thickness. For Milwaukee saw.

PRF-21048BW 8-1/4” 48 5/8”KO MTCG 0 0.087 5800 General purpose. Up to 1/8” wall thickness. For Circular saws.

PRF-23048CBN 9” 48 1” ATB 0 0.087 3700 General purpose. Up to 1/8” wall thickness. For 9” saws.

PRF-25550D 10” 50 1”, 5/8” TCG 0 0.091 2500 General purpose. Up to 1/8” wall thickness. For 10” DRY CUTTERS ONLY

PRF-25550DT

10” 50 1” TCG 0 0.079 2500 General purpose. Up to 1/4” wall thickness. For 10” DRY CUTTERS ONLY

PRF-30560D 12” 60 1” TCG 0 0.098 2000 General purpose. Up to 3/8” wall thickness. For 12” Dry cutters (JEPSON, Makita, etc)

PRF-35572D 14” 72 1” TCG 0 0.094 1700 General purpose. Up to 3/8” wall thickness. For 14” Dry cutters

PRF-40580D 16” 80 1” TCG 0 0.102 1700 For Dry cutters. Or foam insulated panel cutting with Makita beam saw

Steel-Pro® Series

For Cordless Saws, see also Cord-Free for Ferrous - page 7

There may be other brands out there, but experience tells us that TENRYU is the one that

industry turns back to for the most reliable, consistent quality.

Steel-Pro Series

®

TENRYU’s steel cutting

carbide tipped saw blades give

INDUSTRIAL PERFORMANCE

C

L

Steel-Pro

®

Series

8

NEW

NEW

NEW

Heavy Metal/Heavy Metal Plus Series

Line Items

Coated Silencer Series

NEW

NEW

NEW

Heavy Metal/Heavy Metal Plus Series

Line Items

Coated Silencer Series

Cut ferrous metals (mild steel) faster, cleaner and easier. Save time, money, the environment, and

your respiratory health.

TENR

YU’S complete series of steel cutting saw blades called “Steel-Pro®” makes light work out of all

kinds of mild steel: steel studs, steel sheet, steel pipe, channel, threaded rod and much, much more.

Specially formulated C-6 carbide grade, combined with our unique tip design, r

esists breakage on

impact and lasts longer, much longer than standard carbides or abrasive discs. Special tooth

geometry with “inserted” tooth design greatly improves security of the tip, efficiency and durability.

Abrasive discs thr

ow sparks and lots of dust including unhealthful fiberglass. You shouldn’t be

breathing it in!

Steel-Pr

o® blades reduce spark production and eliminate abrasive wheel dust.

Abrasive discs wear quickly, requiring frequent blade changes. Steel-Pro® blades allow you to keep

working; eliminating down time for frequent blade changes. In addition, Steel-Pro® cuts 5 to 10

times faster than abrasives. Typically, one Steel-Pro® blade will outlast somewhere between 15 to

30 abrasive blades. Think of all that non-productive “down time”.

Abrasive discs leave a sharp burr at the cutting edge that must be r

emoved later. Steel-Pro® blades

cut clean; eliminating this extremely time-consuming after-cut process. “Time is money”. Steel-Pro®

saves you BOTH!

EACH BLADE FEATURES:

•