UNITED STATES

CONSUMER PRODUCT SAFETY COMMISSION

4330 EAST WEST HIGHWAY

BETHESDA, MD 20814

CPSC Hotline: 1-800-638-CPSC(2772) CPSC's Web Site: http://www.cpsc.gov

Page 1 of 2

DATE:

BALLOT VOTE SHEET

TO:

The Commission

Alberta E. Mills, Secretary

THROUGH:

Patricia M. Hanz, General Counsel

Mary T. Boyle, Executive Director

FROM:

Patricia M. Pollitzer, Assistant General Counsel

Hyun S. Kim, Attorney, OGC

SUBJECT:

Draft Notice of Availability: Table Saw Blade-Contact Injuries Special Study

Report, 2017

BALLOT VOTE DUE: ____________________

CPSC staff has completed the report titled, Table Saw Blade-Contact Injuries Special

Study Report, 2017. The Office of the General Counsel has prepared a draft Federal Register

notice of availability (NOA) for the Commission’s consideration. The draft NOA announces the

availability of the report and asks for public comment on the report.

Please indicate your vote on the following options:

I. Approve publication of the attached NOA in the Federal Register, as

drafted.

(Signature)

(Date)

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

This document has been electronically

approved and signed.

November 14, 2018

Tuesday, November 20, 2018

Page 2 of 2

II. Approve publication of the attached NOA in the Federal Register, with changes. (Please

specify changes.)

(Signature)

(Date)

III. Do not approve publication of the attached NOA in the Federal Register.

(Signature)

(Date)

IV. Take other action. (Please specify.)

(Signature)

(Date)

Attachment: Draft Federal Register Notice: Notice of availability: Table Saw Blade-Contact

Injuries Special Study Report, 2017

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

DRAFT

1

[Billing Code 6355-01-P]

CONSUMER PRODUCT SAFETY COMMISSION

Notice of Availability: Table Saw Blade-Contact Injuries Special Study Report, 2017

[Docket No. CPSC-2011-0074]

AGENCY: U.S. Consumer Product Safety Commission.

ACTION: Notice of availability.

SUMMARY: The Consumer Product Safety Commission (CPSC) is announcing the

availability of a report titled, “Table Saw Blade-Contact Injuries Special Study Report,

2017.” The CPSC requests comments on the report.

DATES: Submit comments by [Insert date 60 days after date of publication in the

Federal Register].

ADDRESSES: You may submit comments, identified by Docket No. CPSC-2011-0074,

by any of the following methods:

Electronic Submissions: Submit electronic comments to the Federal eRulemaking

Portal at: http://www.regulations.gov. Follow the instructions for submitting comments.

The CPSC does not accept comments submitted by electronic mail (e-mail), except

through www.regulations.gov. The CPSC encourages you to submit electronic

comments by using the Federal eRulemaking Portal, as described above.

Written Submissions: Submit written submissions by mail/hand delivery/courier

to: Division of the Secretariat, Consumer Product Safety Commission, Room 820, 4330

East West Highway, Bethesda, MD 20814; telephone (301) 504-7923.

DRAFT

2

Instructions: All submissions received must include the agency name and docket

number for this notice. All comments received may be posted without change, including

any personal identifiers, contact information, or other personal information provided, to:

http://www.regulations.gov. Do not submit confidential business information, trade

secret information, or other sensitive or protected information that you do not want to be

available to the public. If furnished at all, such information should be submitted in

writing.

Docket: For access to the docket to read background documents or comments

received, go to: http://www.regulations.gov, and insert the docket number CPSC-2011-

0074, into the “Search” box, and follow the prompts.

FOR FURTHER INFORMATION CONTACT: Caroleene Paul, Directorate

for Engineering Sciences, U.S. Consumer Product Safety Commission, 5 Research Place,

Rockville, MD 20850; telephone: 301-987-2225; email: cpaul@cpsc.gov.

SUPPLEMENTARY INFORMATION:

On May 12, 2017, the CPSC published in the Federal Register a notice of

proposed rulemaking (NPR) on a safety standard for table saw blade-contact injuries. 82

FR 22190. In January 2017, staff began collecting additional information on incident

data identified in the National Electronic Injury Surveillance System (NEISS) for table

saws to: (1) obtain information regarding the type of table saws involved in the cases to

generate national estimates by saw type and estimated risk of injury associated with each

table saw type; (2) gain information regarding the type and usage pattern of the blade

guard; and (3) collect additional injury and incident data.

DRAFT

3

On April 27, 2017, the Commission held a decisional hearing on the NPR. The

Commission directed “staff to analyze and seek public comment on the Table Saw Study

started in January 2017, based on the most appropriate time period that will generate

information to determine a national estimate from NEISS incidents. Results will be

published in the Federal Register for notice and comment as part of the docket for this

rulemaking.”

CPSC staff has completed the report titled, Table Saw Blade-Contact Injuries

Special Study Report, 2017. The report is available on the CPSC’s website at:

_________________, and in http://www.regulations.gov, under Supporting and Related

Materials, docket number CPSC-2011-0074, and from the CPSC’s Division of the

Secretariat, at the location listed in the ADDRESSES section of this notice.

The CPSC invites comments on the report. Comments should be submitted by

[Insert date 60 days after date of publication in the Federal Register]. Information on

how to submit comments can be found in the ADDRESSES section of this notice.

Dated: _________

_____________________________________

Alberta E. Mills, Secretary

Consumer Product Safety Commission

UNITED STATES

CONSUMER PRODUCT SAFETY COMMISSION

4330 EAST WEST HIGHWAY

BETHESDA, MD 20814

Memorandum

1

Date: November 13, 2018

TO :

The Commission

Alberta E. Mills, Secretary

THROUGH:

Mary T. Boyle, Executive Director

Patricia M. Hanz, General Counsel

FROM:

George A. Borlase, Ph.D., P.E., Assistant Executive Director

Office of Hazard Identification and Reduction

Caroleene Paul, Table Saw Project Manager

Division of Mechanical and Combustion Engineering, Directorate for

Engineering Sciences

SUBJECT:

The 2017 NEISS Table Saw Special Study

1

This briefing package contains the results of the 2017 NEISS special study for table saw blade-

contact injuries. There are three tabs summarizing the study’s results:

Tab A: Garland, S. and Tu, Y. Table Saw Blade-Contact Injuries Special Study Report, 2017.

U.S. Consumer Product Safety Commission, November 2018.

In this report, Directorate for Epidemiology staff summarizes the 2017 Table Saw Special

Study’s background, design, and the methodology to generate national emergency department-

treated, table saw blade-contact, injury estimates. It also provides the response rates, reports the

national injury estimates and risk estimates, and contains results of a case-level analysis

completed by staff.

Tab B: Goldsmith, J. Table saw blade-contact injuries. Memorandum, U.S. Consumer Product

Safety Commission, November, 13, 2018.

In this memorandum, Directorate for Health Sciences staff discusses the findings of the analysis

of the 2017 NEISS data in terms of the injury diagnoses and provides the reasoning for the

review team’s decision to change injury diagnoses in some cases to characterize more accurately

the injuries sustained.

1

This analysis was prepared by CPSC staff. It has not been reviewed or approved by, and may not necessarily

reflect the views of, the Commission.

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

This document has been electronically

approved and signed.

2

Tab C: Bailey, M. Table Saw Population Estimates for 2017. Memorandum, U.S. Consumer

Product Safety Commission, November 13, 2018.

In this memorandum, Directorate for Economic Analysis staff provides estimates of the number

of table saws in use in 2017 and estimates the proportion that were equipped with the modular

blade guards required under the 7

th

edition of UL 987. This memorandum presents an overview

of the data used in the analysis and describes the methodology and results of the analysis.

Additionally, an appendix presents an analysis evaluating the sensitivity of the risk findings

developed by the Directorate for Epidemiology to possible variations in the estimated proportion

of table saws equipped with the modular blade guard systems.

Recommendation

CPSC staff recommends publishing a Federal Register notice indicating the availability of the

study results (i.e., this briefing package) on CPSC.gov with a 60-day public comment period.

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

3

Tab A

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

4

Table Saw Blade-Contact Injuries

Special Study Report, 2017

November 2018

Sarah Garland, Ph.D.

Yongling Tu, M.S.

Directorate of Epidemiology

Division of Hazard Analysis

U.S. Consumer Product Safety Commission

4330 East West Highway

Bethesda, MD 20814

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

5

I.

Executive Summary

In January 2017, CPSC staff initiated a special study to obtain emergency department-treated, table saw

blade-contact injury estimates for saw, incident, and injury characteristics, which are otherwise not

available in the standard NEISS data collections. In April 2017, the Commission directed staff to publish

the results for comment after the study’s completion and analysis. This report provides the results of

this study.

Study Response Rates

• For the product codes 0841 (table saws), 0845 (saws, not specified), and 0895 (power saws,

other or not specified), there were 1,342 cases identified in the NEISS, with treatment dates

between January 1, 2017 and December 31, 2017, and with a final weight greater than zero.

2

o There were 202 cases from “non-participating” hospitals. Because non-participating

hospitals do not provide patient identification, staff excluded these hospitals’ case from

follow-up investigations.

3

o For the eligible 1,140 cases from “participating hospitals”:

246 cases did not have to be assigned because the NEISS narrative indicated

that a table saw was not involved or blade contact did not occur;

128 cases did not provide victim contact information;

CPSC Field staff terminated 476 cases where no patient contact was made, the

victim refused to participate, or the case did not meet study criteria; and

Field staff completed investigations for 290 cases.

• The overall response rate for the entire study was 39.9 percent.

• For the cases where CPSC staff requested In-Depth Investigations (IDIs) to be attempted, the

response rate was 32.4 percent.

• Of the 290 completed IDIs, 161 involved a table saw blade-contact injury.

Estimated Table Saw Blade-Contact Injuries, 2017

• In 2017, there were an estimated 26,500 table saw blade-contact, emergency department-

treated injuries, with a 95 percent confidence interval of 25,200–27,800.

• Of the estimated 26,500 table saw blade-contact injuries, the table saw type distribution is:

o bench saws were an estimated 60.7 percent of the injuries (16,100);

o contractor saws were an estimated 26.6 percent of the injuries (7,000); and

o cabinet saws were an estimated 9.2 percent of the injuries (2,400).

• Of the estimated 26,500 table saw blade-contact injuries, the blade guard use distribution is:

o the blade guard was not in use in an estimated 88.9 percent of injuries (23,600);

o the blade guard was in use in an estimated 6.3 percent of injuries (1,700); and

o unknown blade guard use or situations where blade guard use is not applicable were the

remaining proportion of injuries.

• Of the estimated 26,500 table saw blade-contact injuries:

o the largest estimated proportion of injuries was for the disposition of treated and

released (86.4 percent; 22,900);

o the largest estimated proportion of injuries was to males (91.9 percent; 24,400);

o the largest estimated proportion of injuries was to the finger (96.4 percent; 25,600); and

2

See “The 2017 Study Description” section for a detailed explanation of the study design.

3

A “participating hospital” is defined as an active NEISS hospital that provides patient identification, if available, on

a case-by-case basis, as requested by CPSC staff. A “non-participating hospital” is an active NEISS hospital that

never provides any patient identification to CPSC as part of their contract. See Section VI for details.

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

6

o the largest estimated proportion of injuries was to the ≥61 years age group (52.5

percent; 13,900).

Diagnosis

• There were 15 completed table saw blade-contact investigations where the corresponding NEISS

diagnosis was inappropriate or incorrect (Goldsmith, 2018). The diagnoses in these cases were

changed throughout all analyses in this report.

• The NEISS diagnosis options available also presented a challenge in characterizing table saw

blade-contact injuries. The subject matter experts (SMEs) agreed to add a diagnosis of severe

laceration. The details are found in Tab B of this package (Goldsmith, 2018). In this report, the

estimated injury results are labeled as “reviewed diagnosis.”

• This report provides the estimated number of injuries and estimated proportions of the

distribution of injuries for both the NEISS diagnosis and the reviewed diagnosis (Table 10).

Risk of Estimated Table Saw Blade-Contact Injuries, 2017

• In 2017, there were an estimated 6.9 million table saws in use, which leads to the estimated risk

of 38.62 blade-contact injuries per 10,000 table saws in use (95 percent confidence interval of

36.76 to 40.47).

o The estimated number of bench saws in use is 4.0 million, which gives the estimated risk

as 40.11 bench saw blade-contact injuries per 10,000 bench saws in use.

o The estimated number of contractor saws in use is 1.4 million, which gives the

estimated risk as 50.19 contractor saw blade-contact injuries per 10,000 contractor

saws in use.

o The estimated number of cabinet saws in use is 1.4 million, which gives the estimated

risk as 16.91 cabinet saw blade-contact injuries per 10,000 cabinet saws in use.

• In 2017, the estimated number of table saws in use that conform to UL 987, 7

th

edition

(conforming saws), is 3.9 million (57 percent). The indicator of a conforming saw in this injury

study was a saw manufactured with a modular blade guard.

o The estimated number of injuries associated with a conforming table saw is 3,200,

which is 12.2 percent of the total 26,500 estimated table saw blade-contact injuries.

o Of the estimated 21,000 injuries where the type of blade guard manufactured with the

saw is known, the estimated proportion of injuries for conforming saws is 15.4 percent.

o There is a significant proportion of injuries associated with “unknown” blade guard type

as manufactured with the table saw (19.6 percent; 5,200).

o The estimated risk of blade-contact injury associated with conforming table saws is 8.19

per 10,000 conforming saws. The estimated risk of blade-contact injury with a saw

manufactured with a traditional blade guard is 60.76 per 10,000 table saws with a

traditional blade guard.

o In 2017, the estimated relative risk of a blade-contact injury is 7.19 times more on a saw

with a traditional blade guard than on saw with a modular blade guard.

Case-Level Incident Analysis

• Section IX of this report summarizes the results of 161 investigations completed by CPSC Field

staff for injury cases involving table saw blade contact, which inform the estimated injuries. A

team of CPSC SMEs reviewed each incident in the study, and coded variables regarding the

product involved, the injury, and the incident scenario.

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

7

II.

Table of Contents

I. Executive Summary ............................................................................................................................... 5

II. Table of Contents .................................................................................................................................. 7

III. List of Tables ......................................................................................................................................... 7

IV. List of Figures ........................................................................................................................................ 8

V. Introduction .......................................................................................................................................... 9

VI. The 2017 Study ................................................................................................................................... 10

The 2017 Study Description .................................................................................................................... 10

Eligible Study Cases ................................................................................................................................. 11

The 2017 Study Response Rates ............................................................................................................. 12

Completed IDI Product Identification and Blade-Contact Status ........................................................... 14

VII. Estimated Emergency Department-Treated, Table Saw Blade-Contact Injuries, 2017 ...................... 15

VIII. Estimated Risk of Emergency Department-Treated, Table Saw Blade-Contact Injuries, 2017 .......... 20

IX. Case-Level Incident Analysis ............................................................................................................... 23

X. Appendix A: Estimation Methodology for a Field Staff Investigation Study of the NEISS .................. 43

XI. Appendix B: NEISS Case Assignment Process Flow ............................................................................. 50

XII. Appendix C: SME IDI Review Process and Variable Descriptions........................................................ 51

NEISS Variables ....................................................................................................................................... 51

Saw Variables .......................................................................................................................................... 52

Injury Variables ....................................................................................................................................... 54

Incident Variables ................................................................................................................................... 55

III.

List of Tables

Table 1: NEISS Product Codes for Initial Scope of Table Saw Studies ......................................................... 11

Table 2: Case Distribution for Participating (Provides Victim Contact, if Available)................................... 11

Table 3: Eligible Cases Distribution ............................................................................................................. 12

Table 4: Investigation Response Types and Results .................................................................................... 13

Table 5: Product and Scope Identification for All Completed IDIs .............................................................. 14

Table 6: Blade Contact and Scope Identification for the 180 Completed Table Saw IDIs .......................... 15

Table 7: 2017 NEISS Estimated Injuries for Product Codes 0841, 0845, 0895............................................ 16

Table 8: Estimated 2017 Emergency Department-Treated, Table Saw Blade-Contact Injuries (Level 1) ... 16

Table 9: 2017 Estimated Emergency Department-Treated Injuries by Category (Level 2) ........................ 18

Table 10: Estimated Emergency Department-Treated Injuries by Category (Level 2), Diagnosis .............. 19

Table 11: Estimated Risk of Table Saw Blade-Contact Injury by Table Saw Type, 2017 ............................. 21

Table 12: Estimated Risk of Table Saw Blade-Contact Injury by Guard Type, 2017 ................................... 22

Table 13: NEISS Variables in Table Saw Blade-Contact Injury Completed IDIs ........................................... 24

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

8

Table 14: NEISS Diagnosis Versus SME Additional Analysis of Injury Diagnosis in Table Saw Blade-Contact

Injury Completed IDIs ................................................................................................................................. 25

Table 15: Hand Injury Variables in Table Saw Blade-Contact Injury Completed IDIs ................................. 25

Table 16: Table Saw Variables in Table Saw Blade-Contact Injury Completed IDIs .................................... 26

Table 17: Table Saw Type Versus Operator’s Use Frequency of the Saw in Table Saw Blade-Contact Injury

Completed IDIs ............................................................................................................................................ 27

Table 18: Manufactured Guard Type Versus Guard Type Received By the Operator in Table Saw Blade-

Contact Injury Completed IDIs .................................................................................................................... 27

Table 19: Manufactured Guard Type Versus SME Reviewed Diagnosis in Table Saw Blade-Contact Injury

Completed IDIs ............................................................................................................................................ 28

Table 20: Blade Guard Variables in Table Saw Blade-Contact Injury Completed IDIs ................................ 29

Table 21: Guard Use by Table Saw and Guard Characteristics in Table Saw Blade-Contact Injury

Completed IDIs ............................................................................................................................................ 31

Table 22: Guard Manufactured with Saw by When the Guard Was Removed in Table Saw Blade-Contact

Injury Completed IDIs Where the Blade Guard Was Not in Use (n = 141) ................................................. 32

Table 23: Guard Manufactured with Saw by Through/Non-through Cuts in Table Saw Blade-Contact

Injury Completed IDIs Where the Blade Guard Was Not in Use (n = 141) ................................................. 33

Table 24: Incident Characteristics in Table Saw Blade-Contact Injury Completed IDIs .............................. 36

Table 25: Stock Dimensions in Table Saw Blade-Contact Injury Completed IDIs ....................................... 37

Table 26: How Blade Contact Occurred in Table Saw Blade-Contact Injury Completed IDIs ..................... 38

Table 27: Manufactured Guard Type Versus How Blade Contact Occurred (High-Level Categories) in

Table Saw Blade-Contact Injury Completed IDIs ........................................................................................ 38

Table 28: Unexpected Workpiece Movement in Table Saw Blade-Contact Injury Completed IDIs ........... 39

Table 29: Manufactured Guard Type Versus Unexpected Workpiece Movement in Table Saw Blade-

Contact Injury Completed IDIs .................................................................................................................... 39

Table 30: How Blade Contact Occurred Versus Unexpected Workpiece Movement ................................. 40

Table 31: How Blade Contact Occurred Versus Blade Guard Use in Table Saw Blade-Contact Injury

Completed IDIs ............................................................................................................................................ 40

Table 32: Circumstances Leading to Blade Contact in Table Saw Blade-Contact Injury Completed IDIs ... 42

Table 33: Bootstrap Bias Estimates for Level 1 and Level 2 Theta Estimates ............................................. 49

IV.

List of Figures

Figure 1: Saw Safety Devices by Blade Guard in Table Saw Blade-Contact Completed IDIs, when Blade

Guard Use is Applicable and Known (n=155 of the 161 cases) ................................................................... 34

Figure 2: Operator Safety Clothing/Gear in Table Saw Blade-Contact Injury Completed IDIs ................... 35

Figure 3: Circumstance for How Blade Contact Occurred in Table Saw Blade-Contact Injury Completed

IDIs .............................................................................................................................................................. 41

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

9

V.

Introduction

On April 27, 2017, the CPSC held a decisional hearing on a notice of proposed rulemaking (NPR)

regarding the safety standard for table saw blade-contact injuries. In their briefing package to the

Commission, staff provided the statistical analysis of the NEISS cases for product code 0841 (table

saws).

4

Staff also provided a history and timeline of prior statistical studies for table saw-related

injuries, and explained why staff was not relying on those prior studies for the briefing package. For the

history of table saw injury studies conducted by the CPSC, see Tab B of the NPR briefing package. CPSC

staff noted in the briefing package that the lack of injury estimates by type of saw negatively impacts the

ability of staff to complete a full benefit-cost analysis. Therefore, in addition to the table saw injury

analysis provided in staff’s NPR briefing package, Tab B, CPSC staff developed a new study based on the

NEISS and conducted by CPSC Field staff investigators. CPSC staff called this study the 2017 NEISS Table

Saw Special Study (2017 Study). The goals of the study were: (1) to obtain information regarding the

type of table saws involved in the cases to generate national estimates by saw type and the estimated

risk of injury associated with each table saw type, (2) to gain information regarding the type and usage

pattern of the blade guard, and (3) to collect additional injury and incident details. The study began in

January 2017. At the public hearing on April 27, 2017, the Commission directed staff to completed the

study and provide a notice in the FR.

This report summarizes the 2017 Study’s design and the methodology developed by staff to generate

national estimates; it provides the response rates, and it reports the national estimates and risk

estimates, as indicated in the goals above.

Although this report summarizes the statistical results from the 2017 Study, another dimension of the

information collected in the study is the specific data regarding the injuries for table saw blade contact.

Thus, included as part of the results of this 2017 Study is an injury analysis completed by CPSC’s

Directorate for Health Sciences (Goldsmith, 2018). For risk estimates, CPSC’s Directorate for Economic

Analysis completed an analysis of estimated table saw in use (Bailey, 2018), which is provided as part of

the results of this analysis.

4

https://cpsc.gov/s3fs-public/Proposed%20Rule%20-%20Safety%20Standard%20for%20Blade-

Contact%20Injuries%20on%20Table%20Saws%20-%20January%2017%202017.pdf

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

10

VI.

The 2017 Study

The 2017 Study Description

The NEISS is a national stratified probability sample of hospitals in the United States and its territories.

There are five strata in the NEISS: children’s hospitals, small hospitals, medium hospitals, large hospitals,

and very large hospitals. Within each stratum is a sample of hospitals that makes up the primary

sampling units (PSUs) of the NEISS. For each hospital in the sample, every emergency department visit

that is associated with a consumer product is recorded. To facilitate injury estimates associated with a

product or product group, each injury has a product code that identifies the type of product involved,

and weight (i.e., the inverse of the probably of selection, adjusted for any nonresponse), which gives the

numerical representation of each case to the number of people that that case represents. Other

product-specific information, such as the name of the manufacturer, is not recorded in the NEISS.

Information recorded for each injury includes sex, age, diagnosis, disposition, and body part, among

other information. The information on stratum, hospital, age, and sex of the patient is known for all

observations in this study. Additional information about the NEISS can be found online at:

http://www.cpsc.gov/library/neiss.html

.

When resources allow, follow-up special studies are performed based on the NEISS data collected.

These special studies are often focused on a product or group of products and are used to gather more

specific information about the product(s) involved and the hazard scenario surrounding incidents.

Almost all recent special studies have used computer-assisted telephone interview (CATI) surveys to

collect information about the incident from the patient, or someone closely associated with the patient

with knowledge of the incident, such as a family member. However, due to table saw data-collection

issues documented previously, which included significant interviewer effects in several questions from

the survey,

5

in January 2017, CPSC staff began a NEISS special study collecting additional incident data

from CPSC field staff IDIs for in-scope table saw cases treated in hospitals in the year 2017, instead of

using formal survey data collection methods. This is the 2017 Study that is the subject of this report.

Appendix C describes the SME review process and final analytic data set obtained from the 2017 Study

for the set of table saw completed IDIs.

There is a product code for table saws specifically in the NEISS (0841); however, hospital coders can only

use this code if the patient used the words “table saw,” and the words “table saw” were recorded in the

hospital record. If a less-specific description is used, then a less-specific product code is used: either

0845 (saws, not specified), or 0895 (power saws, other or not specified). Cases using the less-specific

product codes (0845 and 0895) could include table saws, although the proportion of table saw cases

may be small. Nevertheless, all cases required review or investigation to discover whether the case

involved a table saw and met the study’s design requirements for the goal of obtaining accurate

estimates of table saw blade-contact injuries. Thus, staff set the initial scope of the study to review all

cases with the product codes 0841, 0845, and 0895. This covered 1,342 cases for treatment dates

January 1, 2017 through December 31, 2017, with final weight greater than zero.

5

https://cpsc.gov/s3fs-public/Proposed%20Rule%20-%20Safety%20Standard%20for%20Blade-

Contact%20Injuries%20on%20Table%20Saws%20-%20January%2017%202017.pdf (Tab B)

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

11

Eligible Study Cases

Weekly during the study, CPSC staff reviewed incoming cases from the hospitals in the NEISS with the

product codes 0841 (table saws), 0845 (saws, not specified), and 0895 (power saws, other or not

specified), to determine whether a follow-up investigation was applicable for the case, based on the

study criteria (the case from a “participating hospital” could have involved table saw blade contact). If

staff determined a case met the study criteria for a follow-up investigation, staff submitted the

investigation request and the process of obtaining patient identification from the treating hospital

began. This section summarizes the results of this process.

Altogether, there were 1,342 cases identified in the NEISS, with treatment dates between January 1,

2017 and December 31, 2017; product codes of 0841 (table saws), 0845 (saws, not specified), or 0895

(power saws, other or not specified); and with a final weight greater than zero. Table 1 provides the

product code breakdown for the initial set of cases with at least one of the three product codes in the

2017 treatment timeframe.

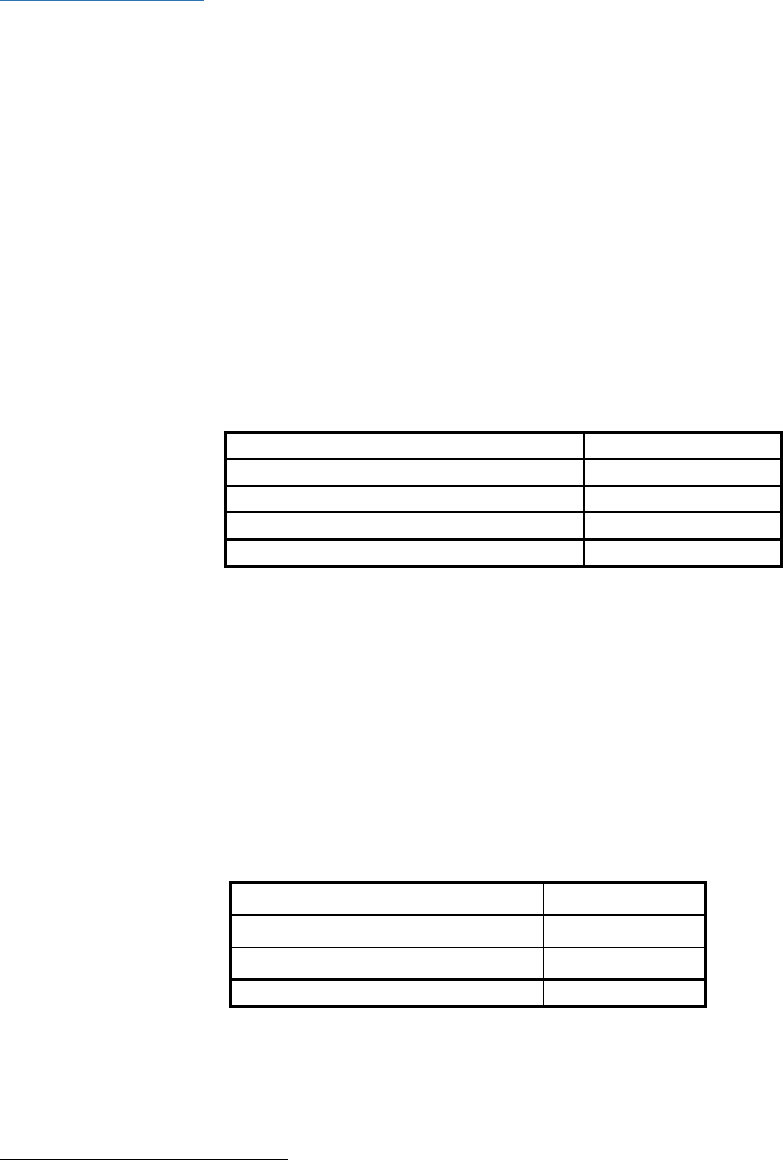

Table 1: NEISS Product Codes for Initial Scope of Table Saw Studies

Product Code

Number of Cases*

0841 (Table Saws)

691

0845 (Saws, not specified)

300

0895 (Power Saws, other or not specified)

351

Total

1,342

*

There were two cases in the study period that were associated with both product code 0841 and 0895; these two

cases are counted in the 0841 product code category only in this table.

Not all of the 1,342 cases were considered eligible for an IDI, although they all inform the study results

in some manner (Appendix A). Not all of the NEISS hospitals participate in providing contact information

for cases they have submitted. Accordingly, cases from non-participating hospitals had to be removed

as eligible study cases because CPSC cannot follow up where no contact information is provided. There

were 202 cases from these non-participating hospitals (Table 2); thus, 202 cases were excluded from the

possibility of a follow-up investigation.

Table 2: Case Distribution for Participating (Provides Victim Contact, if Available)

Versus Non-Participating NEISS Hospitals

Case from a Participating Hospital

Number of Cases

No

202

Yes

1,140

Total

1,342

Once the cases from non-participating hospitals were removed, CPSC staff reviewed the remaining 1,140

cases and did not assign for follow-up investigation those that were clearly not table saw injuries or

were clearly injuries not resulting from table saw blade contact.

6

CPSC staff completed this step by

reviewing, weekly for the entire year, a total of 1,140 NEISS cases and removing any cases that

6

Due to the increase in resources required for a Field staff investigation-based study compared to a CATI-based

study, where all cases would be assigned for further data collection, CPSC staff did not request investigations for

these cases. However, the non-assigned cases play an integral role in the analysis methodology; see Appendices A

and B for details.

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

12

indicated, or for which staff could assume reasonably, that a table saw was not involved (e.g., cases

indicating the victim was trimming a tree) or where no blade contact occurred (e.g., corneal abrasions

due to debris while using a table saw). This left 894 cases eligible for investigation assignment requests

(Table 3); that is, 894 cases that came from a hospital that could provide contact information, if

available, and the emergency department visit could be from a table saw blade-contact incident, which

qualifies the case for a follow-up investigation to gather more specific, objective product information.

CPSC staff submitted requests for CPSC Field staff investigations on a weekly schedule throughout the

study.

Table 3: Eligible Cases Distribution

Case Eligible for Assignment

(based on staff case review)

Number of Cases

No

246

Yes

894

Total 1,140

The 2017 Study Response Rates

Table 4 provides the number of cases and percentage of cases for each type of response available in the

2017 Study, for all 1,342 cases for product codes 0841 (table saws), 0845 (saws, not specified), and 0895

(power saws, other or not specified), with a final NEISS weight greater than zero. As discussed in the

previous section, not all cases were eligible for follow-up investigation, although these cases inform the

final analysis of the study, as part of the denominator of the level 1 correction factor as cases that did

not involve table saw blade contact. Because the NEISS design captures only the first emergency

department visit for each incident and patient, duplicate cases (i.e., re-visits for the same patient and

incident) are considered out of scope for the NEISS and removed from the analyses altogether.

However, two cases involved the same victim, but for two separate incidents. Both of these cases are

in-scope for the study; CPSC Field staff completed only one IDI for both incidents (each incident is listed

separately within the IDI). There are two unique identifiers in the NEISS representing each incident, but

only one identifier for the IDI associated with these two cases. Each NEISS case is considered a

“completed IDI” in Table 4. The final total case count is 1,342 with 290 completed IDIs.

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

13

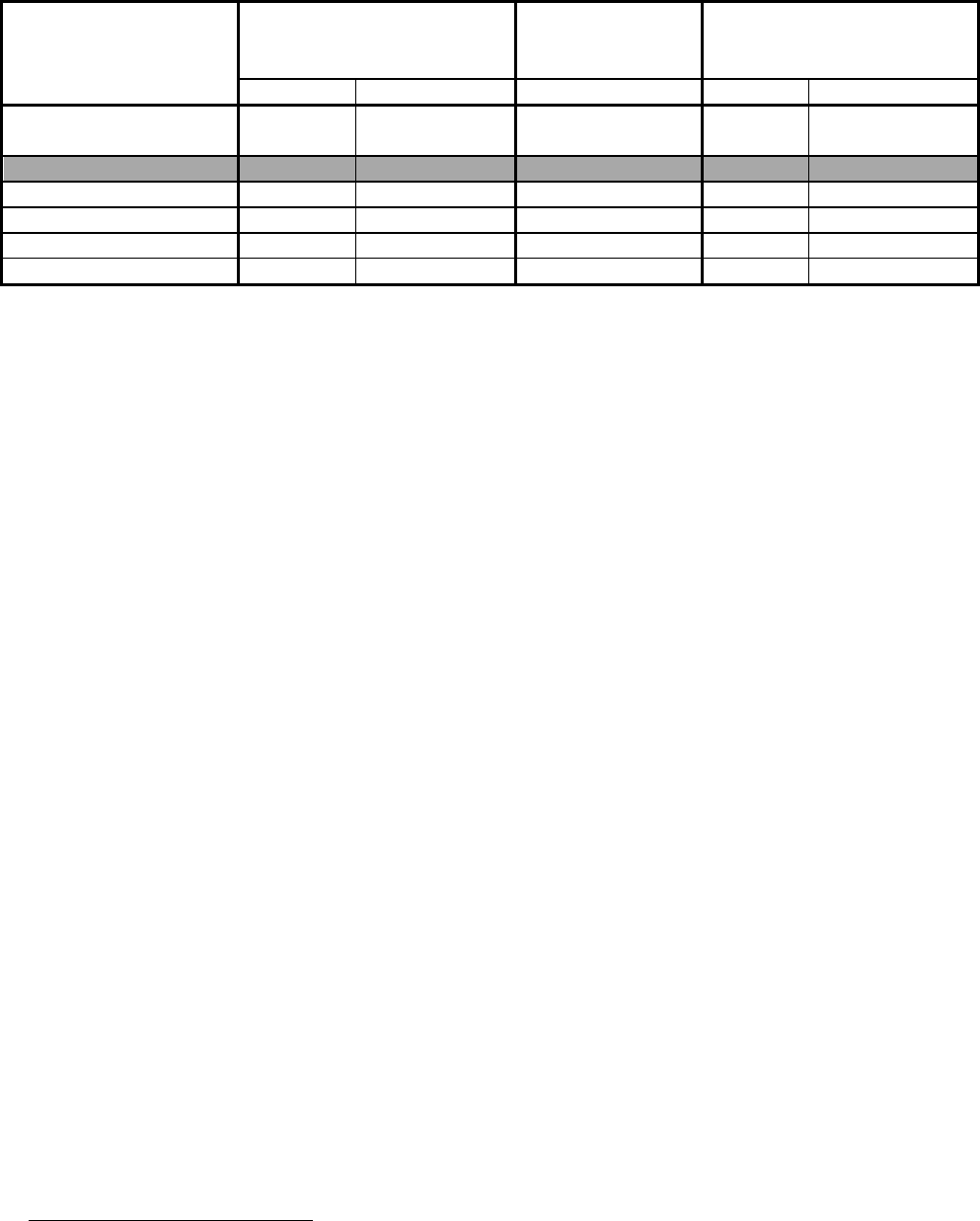

Table 4: Investigation Response Types and Results

Status

Number of Cases

Percent of Total

7

Nonresponses

Non-participating hospital 202 15%

No patient contact information available

128

10%

Terminated by Field staff

467

35%

Completed IDI, but count as nonresponse

8

9

1%

Responses

Not a table saw; Unknown if table saw, but no

blade contact; or Table saw, but no blade contact

(not assigned for investigation)

246 18%

Completed IDI 290 22%

Total

1,342

100%

For the 1,140 investigation-eligible cases, 246 cases did not have to be assigned because the NEISS

narrative regarding the incident indicated that a table saw was not involved or blade contact did not

occur. The 246 non-assigned cases are counted as responses because they are used within the analytic

methodology to answer part of the study’s overall questions. There were 128 cases without victim

contact information available from participating hospitals. Field staff terminated 467 cases when they

were unable to make contact with the patient, the victim refused to participate, or was unable to meet

study criteria (e.g., instructions to investigators included a description of when one could justify a

termination even with patient contact, because the required information would be unattainable in some

scenarios; for example, when the contact is hostile and no information that is of interest to the study is

obtained during contact).

9

In two of the terminated cases, the cases were received by CPSC staff after

the study’s data cut-off deadline, but were determined eligible for assignment. Thus, CPSC staff

classified these two cases in the “Terminated” category, although they were not assigned to the Field.

Field staff completed investigations for 290 cases. Thus, the overall response rate for the entire study

was 39.9 percent.

10

Of the 894 cases that were assigned for investigation, the hospital could not provide contact information

in 128; Field staff terminated 467 investigations and completed 290 investigations. Thus, for the cases

where CPSC staff requested that investigations be attempted, the response rate for cases with

investigations requested was 32.4 percent.

11

7

Throughout all tables of this this report, percentages may not sum to 100 percent, due to rounding.

8

There were nine completed IDIs that the SME review team marked as a nonresponse, due to the incorrect set of

questions being asked of a victim, the inability to ask most questions of the victim (e.g., a highly reluctant

respondent who essentially refused to participate, and extremely limited information gained), or other similar

circumstances. Thus, these nine IDIs did not meet the study criteria, and these nine cases are included in the

nonresponse category.

9

Unit nonresponse occurs when a case is from a hospital that does not participate in providing victim

identification, no contact was established, victim’s participation refusal, or the study’s criteria is not met.

10

( 1) =

=

= 39.9%. This corresponds to the Level 1 estimates

in the methodology provided in Appendix A, which includes table saw blade-contact estimates.

11

(

2

)

=

=

= 32.4%. This corresponds to the Level 2

estimates in the methodology provided in Appendix A, which includes table saw type estimates.

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

14

Completed IDI Product Identification and Blade-Contact Status

As previously noted, the study’s goals include obtaining additional table saw blade-contact injury

information and extrapolating the data to generate national estimates. The study was initiated with a

broader scope from which one can extrapolate to the specific scope of table saw blade-contact injuries.

This section summarizes the 290 completed IDIs from the study at the product level. This section aims

to give a high-level summary of the completed investigations for the types of products identified and,

for the table saws identified, provide the blade-contact status. Detailed analyses of the table saw cases

are given throughout the remainder of this report.

Table 5 provides the products identified in the 290 completed IDIs cases. There were 180 completed

IDIs that identified a table saw as the product involved in the incident. SMEs determined that blade

contact occurred as the injury mechanism in 161 of the 180 completed IDI table saw cases (Table 6).

Table 5: Product and Scope Identification for All Completed IDIs

Product Type

Frequency

Percent of Total

Completed IDIs

Table saw

180

62.1%

Circular saw

41

14.1%

Powered miter saw/Chop saw

17

5.9%

Manual hand saw

10

3.4%

Grinder

8

2.8%

Reciprocating saw

6

2.1%

Unspecified, handheld, power saw

5

1.7%

Band saw

4

1.4%

No saw involved

4

1.4%

Jigsaw

3

1.0%

Not a table saw, but also out of scope

for the NEISS as a work-related incident

3 1.0%

Radial arm saw

2

0.7%

Biscuit joiner

1

0.3%

Chain saw

1

0.3%

Jointer

1

0.3%

Powered hedge trimmer

1

0.3%

Unspecified power saw

1

0.3%

Unspecified handheld saw

1

0.3%

Unknown saw type

1

0.3%

Total 290 100%

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

15

In calculating the Level 1 adjustment factor estimates (the estimated proportion of table saw blade-

contact injuries of the total 0841, 0845, 0895 estimated injuries), the 161 completed IDIs identified as

blade contact in Table 6 inform the numerator through the methodology described in the following

sections and in Appendix A. The denominator includes the 290 cases in Table 5, and also the 246 cases

that were not assigned (Table 4), due to scope knowledge available at the NEISS case level. These 161

cases move to inform the denominator of the Level 2 adjustment factor estimates, as described in the

following section and Appendix A, while a subset of the 161 inform the numerator, depending on the

Level 2 adjustment factor estimated under consideration.

Table 6: Blade Contact and Scope Identification for the 180 Completed Table Saw IDIs

Completed Table Saw IDI Scope

Frequency

Percent of Total

In-scope blade-contact Injury

161

89%

Not a blade-contact injury

13

7%

Out-of-scope (Occupational injury)

4

2%

Out-of-scope (Homemade table saw)

2

1%

Total

180

100%

VII.

Estimated Emergency Department-Treated, Table Saw Blade-Contact Injuries,

2017

12

Appendix A describes the full mathematical details for calculating injury estimates and associated

variance estimates for each level of incident characteristics. This section describes, more generally, the

process of obtaining injury estimates, and provides the resulting injury estimates for the year 2017.

As noted in The 2017 Study Description section, only table saw blade-contact injuries were the focus of

the study. Therefore, this study can only generate estimates specifically for blade-contact injuries for

table saws, not all injuries. However, to obtain the table saw blade-contact injury estimates, the process

is not simply taking the cases that are table saw blade-contact and summing the weights to obtain

estimates (i.e., the standard method of point estimate calculations for the NEISS). As noted in the

description in Appendix A, the methodology generates a set of adjustment factors (i.e., estimated

proportions that can be applied to a known estimate), to calculate the estimated number of emergency

department-treated injuries for a particular characteristic.

In this study, the known injury estimate (i.e., estimate derived without a special study) is all injuries

related to products in the codes 0841 (table saws), 0845 (saws, not specified), and 0895 (power saws,

other or not specified). The estimated number of injuries from these three product codes, along with

the associated variance estimated, is obtained first through the typical methodology used for obtaining

injury estimates from the NEISS. This is the top-level injury estimate that can be obtained for any year

of the NEISS, not just the special study year, given certain assumptions. In Appendix A, this estimate is

called (pronounced “tau-hat”). Adjustment factors will be applied to this estimate to obtain estimated

injuries for specific incident characteristics. Although this process can be completed for any year of the

NEISS, this section will focus on the year 2017. Table 7 provides the 2017 estimated injuries, with the 95

12

Estimates are rounded to the nearest 100 injuries. Estimated injuries may not sum to subtotal or total due to

rounding. All estimated percentages and proportions are based on unrounded estimates.

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

16

percent confidence interval for the injury estimate, as obtained from the NEISS, for product codes 0841,

0845, and 0895. In 2017, there are an estimated 64,000 injuries related to products in these three

product codes (), with a 95 percent confidence interval of 55,500 to 72,400.

13

Table 7: 2017 NEISS Estimated Injuries for Product Codes 0841, 0845, 0895

Product Codes

2017 Injury

Estimate (

)

95% Confidence Interval for

the 2017 Injury Estimate (

)

0841, 0845, 0895 (All cases) 64,000 55,500 – 72,400

To obtain the estimated number of table saw blade-contact injuries, an adjustment factor is applied to

the 64,000 estimate (i.e., 64,000 is multiplied by an estimated proportion to reduce the estimate to the

measure of interest, in this case, table saw blade-contact injuries). The adjustment factor for table saw

blade-contact injuries is the Level 1 estimate,

(pronounced “theta-L-one-star-hat”), in Appendix A.

The adjustment factor calculated is 0.414, which reduces the = 64,000 estimate to 26,500, which is

called

(pronounced “phi-L-one-hat”) in Appendix A.

14

The

is 26,500, which is the estimated

number of table saw blade-contact injuries. Table 8 summarizes this process with the results.

Table 8: Estimated 2017 Emergency Department-Treated, Table Saw Blade-Contact Injuries (Level 1)

Adjustment

Factor

Estimate

95% Confidence

Interval for

2017 Injury

Estimate

95% Confidence

Interval for the 2017

Injury Estimate

0841, 0845, 0895 (All Cases)

N/A

N/A

= 64,000

55,500 – 72,400

Table saw blade-contact injuries

= 0.414

0.395 – 0.434

= 26,500

25,200 – 27,800

To obtain the estimated number of table saw blade-contact injuries for each type of table saw, along

with other characteristics of the incident, another level of adjustment factors is estimated and applied

to the estimated number of table saw blade-contact injuries that is given in Table 8. The NEISS cannot

collect information at the detailed level of the type of table saw, like a bench saw versus contractor or

cabinet saw, so estimates at this level of detail must rely on data collected through a special study. To

obtain the estimated blade-contact injuries specific for bench saws, the level 2 adjustment factor,

, is

applied to the

= 26,500, reducing this table saw blade-contact injury estimate to represent only the

bench saw blade-contact injuries. Thus, the table saw blade-contact injury estimate for any Level 2

characteristics is the estimate (the overall, unadjusted estimate for all three product codes), multiplied

by both

and

. The combination (i.e., multiplication) of these two correction factors is written as

, as a combined adjustment factor to . This process is completed for any estimate related to a detail

that can only be collected from a follow up with the patient determining further details regarding

incident and injury (Level 2 in the Appendix B flow chart). This is the

estimate in Appendix A.

Table 9 provides the estimated number of table saw blade-contact injuries for estimates for Level 2

characteristics. Level 2 estimates provided are table saw blade-contact injuries by table saw type, guard

13

All injury estimates in this report are rounded to nearest 100.

14

All adjustment factor estimates in this report are rounded to the third decimal place. However, calculations of

injury estimates and their 95% confidence intervals are based on unrounded estimates, and the results are then

rounded for this report.

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

17

usage, guard type as manufactured with the saw, diagnosis, the NEISS disposition, injured body part,

victim’s age group, and victim’s sex. Though other variables the SME review team coded in the study

are considered Level 2 as well, the methodology from Appendix A is computationally intensive, so CPSC

staff limited estimates to this specific set of characteristics, which meet the main goals of the study.

Section IX provides the results of all study variables at the case level without extrapolation to national

estimates.

Part of the first goal of the 2017 Study was to provide estimated injuries by table saw type. Of the

estimated 26,500 table saw blade-contact injuries, an estimated 16,100 (60.7 percent) and 7,000 (26.6

percent) are bench and contractor saws, respectively. The remaining part of the estimated blade-

contact injuries are for cabinet saws and table saws where a type of saw cannot be determined.

Blade guard use was also another area of interest to understand as part of the 2017 Study. In 2017, of

the estimated 26,500 table saw blade-contact injuries, 23,600 (88.9 percent) occurred without a blade

guard in use, while 1,700 occurred with a blade guard in use (6.3 percent). For a more detailed case-

level analysis concerning blade guard use, see Section IX of this report.

In 2017, of the 26,500 estimated table saw blade-contact injuries, an estimated 17,800 (67.0 percent)

occurred on a saw manufactured with a traditional blade guard, while an estimated 3,200 injuries

occurred on a table saw manufactured with a modular blade guard (12.2 percent). A non-trivial

proportion (an estimated 19.6 percent or an estimated 5,200 injuries) of the estimated blade-contact

injuries occurred on a table saw where the type of blade guard manufactured with the saw could not be

determined. With this in mind, considering the estimated injuries where the blade guard type that was

manufactured with the saw was known (21,000), the majority (84.6 percent) of the estimated injuries

are for saws manufactured with a traditional blade guard, and saws manufactured with a modular blade

guard are an estimated 15.4 percent. Note that from a statistical perspective, the breakdown of the

type of blade guard by whether the blade guard is in use is not possible due to the small sample sizes;

however, this additional breakdown is provided at the case level in Section IX.

A majority of the estimated 26,500 table saw blade-contact injuries were treated and released in the

emergency department (22,900; 86.4 percent), while an estimated 11.7 percent (3,100) were

hospitalized (i.e., treated and transferred or treated and admitted).

A majority of the estimated 26,500 table saw blade-contact injuries occurred to at least one finger

(24,400; 91.9 percent) and to males (25,600; 96.4 percent).

About half of the estimated 26,500 table saw blade-contact occurred to the ≥61 age group (52.5

percent; 13,900), while the 41-60 age group and ≤40 age group had an estimated 35.1 percent and 12.4

percent of the injuries (9,300 and 3,300), respectively.

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

18

Table 9: 2017 Estimated Emergency Department-Treated Injuries by Category (Level 2)

Table Saw Blade-Contact

Injuries

15

Estimate

Estimate

2017 Injury

Estimate,

95% CI for the 2017

Injury Estimate

Table Saw Type

0.607

0.252

16,100

15,300 – 16,900

Bench

Contractor

16

0.266

0.110

7,000

6,600 – 7,500

Cabinet

0.092

0.038

2,400

2,200 – 2,700

Unknown

*

*

*

*

Blade Guard Use

0.889

0.368

23,600

22,400 – 24,800

No

Yes

0.063

0.026

1,700

1,500 – 1,900

Unknown

*

*

*

*

N/A

*

*

*

*

Guard Type

Manufactured with Saw

0.670

0.278

17,800

16,800 – 18,700

Traditional

Modular

0.122

0.050

3,200

2,900 – 3,500

Unknown

0.196

0.081

5,200

4,500 – 5,900

None

*

*

*

*

Disposition

0.864

0.358

22,900

21,700 – 24,100

Treated and Released

Hospitalized

17

0.117

0.048

3,100

2,800 – 3,400

Other

*

*

*

*

Body Part

0.919

0.381

24,400

23,100 – 25,600

Finger

Hand

0.073

0.030

1,900

1,700 – 2,200

Other

*

*

*

*

Sex

0.964

0.399

25,600

24,300 – 26,800

Male

Female

*

*

*

*

Age Group

0.124

0.051

3,300

2,600 – 4,000

≤40

41-60

0.351

0.145

9,300

8,800 – 9,800

≥61

0.525

0.217

13,900

13,200 – 14,600

*Indicates an injury estimate that is considered unstable; thus, is not reported in this table.

15

There are 10 cases with completed IDIs that inform the table saw type = “Cabinet” estimate, and similarly, 10

cases for table saw type=“Unknown,” 14 cases for blade guard use = “Yes,” and 15 cases for body part = “Hand.”

Typically, this is a smaller number of cases than usual for producing a stable estimate with the NEISS; however, the

methodology applied here is not the methodology used to generate the reporting criteria for the NEISS. These

estimates otherwise meet the standard NEISS stability criteria, except for table saw type = “Unknown.” These

estimates are reported here, but with this note. However, if an estimate failed a second reporting criteria, as with

table saw type = “Unknown,” the estimate is not reported.

16

The contractor saw category includes contractor saws and hybrid table saws. See Section IX (Table 16).

17

The “Hospitalized” category includes the NEISS dispositions of admitted and transferred.

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

19

In reviewing the additional information obtained through the IDIs, the SME review team determined

that the injuries sustained in these incidents were not easily captured by a single diagnosis code

available in the NEISS (See the “Case-Level Incident Analysis” section of this report and Tab B

(Goldsmith, 2018) for additional details). The injuries were, at times, severe lacerations that the NEISS

had captured through various diagnosis codes, but those single diagnosis codes did not describe the full

extent of the injuries. Additionally, the SME review team determined the NEISS diagnosis was

inappropriate or incorrect in 15 cases. Thus, the SME review team reviewed the information available

and made a determination about the NEISS injury code. This report does not go into the details of these

injuries, but refers the reader to the Directorate for Health Science’s memorandum (Tab B), which is

part of this package and provides a detailed analysis of table saw blade-contact injuries from the 2017

Study (Goldsmith, 2018). The estimated injuries for the NEISS diagnosis and the Reviewed Diagnosis (a

classification that captures more of the extent of the injury), but both incorporating the corrected value

for the 15 inappropriate or incorrect cases, are given in Table 10.

While the laceration diagnosis remained the prevalent diagnosis in table saw blade-contact injuries,

regardless of the classification method, the SME review team’s “reviewed diagnosis” captured severe

lacerations at an estimated 15.1 percent of the estimated 26,500 table saw blade-contact injuries, and

lacerations at an estimated 53.2 percent (estimates of 4,000 and 14,100, respectively). There is a

statistically significant difference between the laceration diagnosis from the NEISS diagnosis and the

reviewed diagnosis of laceration, and the severe laceration classification cannot be compared between

the two, as the severe laceration classification is unique to the 2017 Study, as described.

The amputation diagnosis represents 10.7 percent of the estimated table saw blade-contact injuries for

the NEISS diagnosis, and 13.3 percent of the reviewed diagnosis; there is not a statistically significant

difference between these two estimates. Fracture diagnoses within the NEISS diagnosis often shifted to

the severe laceration category in the reviewed diagnosis; thus, a significant change is seen in the

fracture and other classifications between NEISS diagnosis and reviewed diagnosis. An estimated 20.6

percent of the table saw blade-contact injuries within the NEISS diagnosis are fractures, while fractures

had to be combined with the avulsion diagnosis to yield statistical results in the reviewed diagnosis. See

Table 13 in Section IX for the comparison of the NEISS diagnosis to the reviewed diagnosis, and see

(Goldsmith, 2018) for a detailed analysis of the injuries in the 2017 Study.

Table 10: Estimated Emergency Department-Treated Injuries by Category (Level 2), Diagnosis

Table saw blade-contact

Injuries

18

Estimate

Estimate

2017 Injury

Estimate,

95% CI for the 2017

Injury Estimate

NEISS Diagnosis

0.609

0.252

16,100

15,200 – 17,100

Laceration

Fracture

0.206

0.085

5,500

5,100 – 5,800

Amputation

0.107

0.044

2,800

2,600 – 3,100

Other

0.078

0.032

2,100

1,800 – 2,300

Reviewed Diagnosis

0.532

0.220

14,100

13,200 – 15,000

Laceration

Severe Laceration

0.151

0.063

4,000

3,600 – 4,400

Amputation

0.133

0.055

3,500

3,200 – 3,800

Fracture or Avulsion 0.184 0.076 4,900 4,500 – 5,200

18

from Table 6 (

= 26,500).

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

20

VIII.

Estimated Risk of Emergency Department-Treated, Table Saw Blade-Contact

Injuries, 2017

In the previous section, Table 8 gives the estimated number of table saw blade-contact injuries in 2017.

Table 9 breaks down that estimate for each type of table saw, whenever it is possible. In this section,

the estimated number of injuries is divided by the estimated number of table saws in use

19

to obtain the

estimated risks of injury. Confidence intervals are also provided to understand the results.

20

Table 11 provides the estimated number of table saws in use for all table saw types and by type of table

saw.

21

This estimated number of table saws in use becomes the denominator for the risk of table saw

blade-contact injuries, which is provided as the estimated number of blade-contact injuries per 10,000

table saws in use. For all types of table saws, the estimated risk is 38.62 blade-contact injuries per

10,000 table saws in use, with a 95 percent confidence interval of 36.76 to 40.47.

Bench saws are estimated at approximately 60 percent of the total estimated number of table saws in

use, and contractor and cabinet saws comprise approximately 20 percent each. The estimated risk is

40.11 blade-contact injuries per 10,000 bench saws in use, 50.19 per 10,000 contractor saws in use, and

16.91 per 10,000 cabinet saws in use. The risk of blade-contact injury is highest for contractor saws, and

lowest for cabinet saws, with all risk comparisons being statistically different.

The proportions of the estimated number of table saws in use for bench and contractor saws (58.5

percent and 20.4 percent, respectively) is similar to the proportions of blade-contact injuries for bench

and contractor saw blade contact injuries (60.7 percent and 26.6 percent for bench and contractor saw

injuries, respectively). For cabinet saws, there is observable difference in the proportion of estimated

table saws in use (21.1% of all table saws in use) versus the proportion of blade contact injuries (9.3% of

table saw blade contact injuries).

19

The term “in use” does not refer to the frequency of use, but to the number of units available for use.

20

The variance estimate for the risk estimates are assumed to be the same as the variance for the corresponding

injury estimate. This is not likely the case in reality; however, there is not a closed form of the variance estimator

for the denominator, and it is unlikely that there would be enough of an impact on the confidence interval

calculations for any conclusions to be affected.

21

CPSC’s Directorate for Economics provided the estimated number of table saws in use for this analysis; details

are provided in (Bailey, 2018), which is Tab C of this briefing package.

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

21

Table 11: Estimated Risk of Table Saw Blade-Contact Injury by Table Saw Type, 2017

Table Saw Type

2017 Injury Estimates

Estimated Number

of Saws in Use

(in 10,000’s)*

22

Risk of Table saw blade-

contact Injury per 10,000 Table

Saws in Use

Estimate

95% CI

Estimate

Estimate

95% CI

Table Saw Blade-Contact

(All Table Saw Types)

26,500 25,200 – 27,800 686.32 38.62 36.76 – 40.47

Type of Table Saw

Bench Saw

16,100

15,300 – 16,900

401.28

40.11

38.02 – 42.20

Contractor Saw

7,000

6,600 – 7,500

140.26

50.19

46.84 – 53.54

Cabinet Saw

2,400

2,200 – 2,700

144.78

16.91

15.15 – 18.67

Unknown

*

*

N/A

N/A

N/A

* See (Bailey, 2018), Tab C of this briefing package.

Table 12 considers the risk of injury for table saws in use that conform to UL 987, 7

th

edition, which

requires modular blade guards. For injuries, the assumption is that if a table saw was manufactured

with a modular blade guard, then it is conforming to UL 987, 7

th

edition (conforming saws). Although

this may not be true in 100 percent of the cases, it is a reasonable assumption. Table saws

manufactured with a traditional blade guard are nonconforming saws.

Of the estimated 686,320 table saws available for consumer use in 2017, table saws (all types)

conforming to UL 987, 7

th

edition comprise an estimated 57 percent of table saws in use. The estimated

proportion of blade-contact injuries associated with conforming table saws in 2017 is 12.2 percent

(Table 9); however, there is a significant proportion of blade-contact injuries (19.6 percent) where the

manufacturer-supplied guard type is “unknown.” Thus, considering only estimated blade-contact

injuries where blade guard type is known (21,000), an estimated 15.4 percent (3,200) of blade-contact

injuries are associated with table saws conforming to the voluntary standard, while, of course, the

proportion of table saws in use that are conforming remains at the estimated 57 percent mentioned

above.

In 2017, the estimated risk of a table saw blade-contact injury per 10,000 saws in use that were

manufactured with a traditional blade guard is 60.75, while the estimated risk of a blade-contact injury

per 10,000 modular blade guard saws is 8.19. This gives an estimated relative risk for 2017 of 7.19,

which means that the risk of injury on a saw with a traditional blade guard is about 7 times greater than

on a saw with a modular blade guard.

22

The term “in use” does not refer to the frequency of use, but to the number of units available for use.

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

22

Table 12: Estimated Risk of Table Saw Blade-Contact Injury by Guard Type, 2017

Table Saw Type

2017 Injury Estimates

Estimated Number

of Saws in Use

(in 10,000’s)*

23

Risk of Table Saw Blade-

Contact Injury per 10,000

Table Saws in Use

Estimate

95% CI

Estimate

Estimate

95% CI

Table Saw Blade-Contact (All

Table Saw Types)

26,500 25,200 – 27,800 686.32 38.62 36.76 – 40.47

Type of Guard Manufactured

with Saw

Traditional

17,800

16,800 – 18,700

292.19

60.75

57.53 – 63.99

Modular

3,200

2,900 – 3,500

394.12

8.19**

7.48 – 8.90

Unknown

5,200

4,500 – 5,900

N/A

N/A

N/A

None

24

*

*

N/A

N/A

N/A

* See (Bailey, 2018), Tab C of this briefing package.

**There is a significant proportion of blade contact injuries for which the blade guard type manufactured with the

table saw is “unknown.” This should be considered in understanding the risk of blade-contact associated with

conforming versus nonconforming table saws.

23

The term “in use” does not refer to the frequency of use, but to the number of units available for use.

24

For the “None” category, the saw in this incident, there was no evidence from the investigation that the saw was

originally manufactured with a blade guard, given the saw’s age and reported information regarding the saw (see

Case-Level Incident Analysis for counts of cases for each level).

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

23

IX.

Case-Level Incident Analysis

Previous sections provide national injury estimates based on the results of the 2017 Study. As part of

the study, CPSC Field staff completed 161 investigations for injury cases involving table saw blade

contact.

25

A team of CPSC SMEs reviewed each completed IDI in the study, and the team coded

variables regarding the product involved, the injury, and the incident scenario. This section summarizes

the findings from completed IDIs associated with table saw blade-contact injuries based on the staff

review. Appendix C provides the data review and coding process, and also provides variable definitions

and categories for variables, as applicable.

The 161 completed IDIs on table saw blade-contact injuries informed the adjustment factors for the

table saw blade-contact estimates that were calculated and applied in the prior sections of this report.

This section is not intended to provide national estimates for all the characteristics of these incidents;

instead, this section provides an analysis to understand the types of incidents that have informed the

nationally representative injury estimates set forth in Sections VII and VIII of this report. Neither case

weights, nor adjustment factors, are applied in this section; all frequency and percentages reported are

at the case (anecdotal) level. Thus, the reader should not expect that the percentages presented in this

section match percentages of national estimates provided. To the contrary, the percentages in this

section most likely do not match national estimate proportions, but may be similar, or not, depending

on a number of factors.

Table 13 provides the breakdown of the 161 table saw blade-contact injury, completed IDI cases for the

variables age group, sex, diagnosis, disposition, and body part.

There were 15 cases where the NEISS diagnosis code was determined to be inappropriate or incorrect,

and these 15 cases are reflected in this analysis based on the corrected diagnosis, in both the NEISS

diagnosis variable and in the Reviewed Diagnosis variable. While the Reviewed Diagnosis variable

created a way for the review team to capture the table saw blade-contact injuries in a repeatable and

more descriptive way, these 15 cases were unique. These 15 cases were inappropriate or incorrect in

the original NEISS, and not just inadequate in their description of the injuries; thus, these 15 cases

reflect the corrected diagnosis in both the NEISS Diagnosis variable and Reviewed Diagnoses variable

(Goldsmith, 2018). Similarly, there was one case where the body part coded in the NEISS was not

correct; the body part results throughout this analysis reflect the corrected body part code for the case.

25

As noted in Section VI, there was a total of 290 completed investigations for the whole study. Of these 290

completed IDIs, 129 did not involve a table saw blade-contact injury. Of the 180 table saw completed IDIs, 19 did

not involve blade contact.

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

24

Table 13: NEISS Variables in Table Saw Blade-Contact Injury Completed IDIs

Variable

Frequency

Percent of Total

Age Group

≤40

25

15.5

41-60

55

34.2

≥61

81

50.3

Sex

Male

153

95.0

Female

8

5.0

NEISS Diagnosis

Laceration

105

65.2

Amputation

19

11.8

Fracture

29

18.0

Avulsion

7

4.4

Nerve Damage

1

0.6

Disposition

Treated and Released

132

82.0

Hospitalized

26

26

16.1

Other

3

1.9

Body Part

Finger

145

90.1

Hand

15

9.3

Lower Arm

1

0.6

As described, in reviewing the additional information obtained through the IDIs, the SME review team

often determined that the injuries sustained in these incidents were not easily captured by a single

diagnosis code in the NEISS. As described in Goldsmith, 2018; section 3, provided as Tab B of this

briefing package, some of the limitations arise from the single diagnosis construct of the NEISS.

Additionally, the injuries were, at times, severe lacerations that the NEISS had captured through various

diagnosis codes, but for which no single diagnosis code was sufficient to explain the full extent of the

injuries. Thus, the SME review team reviewed the information available and made a determination

about the NEISS injury code. Table 14 shows the original NEISS diagnosis code compared to the SME

review team’s reviewed-diagnosis determinations. As mentioned previously, there were 15 cases that

the review team determined to be inappropriate or incorrect diagnosis codes in the NEISS, and the

diagnosis has been corrected throughout this analysis and report. There were 29 cases with a reviewed

diagnoses of laceration that the team determined to be an extreme severity. This report does not go

into the details of these injuries, but refers the reader to the Directorate for Health Science’s

memorandum, which is part of this package (Tab B) and provides a detailed analysis of table saw blade-

contact injuries from the 2017 Study (Goldsmith, 2018).

26

The “Hospitalized” category includes the NEISS dispositions of admitted and transferred.

THIS DOCUMENT HAS NOT BEEN REVIEWED

OR ACCEPTED BY THE COMMISSION.

CLEARED FOR PUBLIC RELEASE

UNDER CPSA 6(b)(1)

25

Table 14: NEISS Diagnosis Versus SME Additional Analysis of Injury Diagnosis in Table Saw Blade-Contact Injury

Completed IDIs

n

Row %

SME Reviewed Diagnosis

Total

NEISS Diagnosis*

Laceration

Severe Laceration

Amputation

Fracture

Avulsion

Laceration

80

76.2

22

21.0

0

0.0

2

1.9

1

1.0

105

Amputation

0

0.0

0

0.0

19

100.0

0

0.0

0

0.0

19

Fracture