FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 1 of 29

For the most current and official copy, check QMiS.

Sections in This Document

1. Introduction ............................................................................................................................ 2

2. General Considerations ......................................................................................................... 2

2.1. Accuracy, Precision, and Uncertainty .......................................................................... 3

2.2. Error and Deviation; Mean and Standard Deviation ..................................................... 4

2.3. Random and Determinate Error ................................................................................... 7

2.4. The Normal Distribution ............................................................................................... 7

2.5. Confidence Intervals .................................................................................................... 9

2.6. Populations and Samples: Student’s t Distribution ....................................................... 9

2.7. References ................................................................................................................ 10

3. Data Handling and Presentation .......................................................................................... 10

3.1. Rounding of Reported Data ....................................................................................... 10

3.2. Significant Figures ..................................................................................................... 11

3.2.1. Definitions and Rules for Significant Figures ................................................ 11

3.2.2. Significant Figures in Calculated Results ..................................................... 12

4. Linear Curve Fitting ............................................................................................................. 13

5. Development and Validation of Spreadsheets for Calculation of Data .................................. 15

5.1. Introduction ............................................................................................................... 15

5.2. Development of Spreadsheets .................................................................................. 15

5.3. Validation of Spreadsheets ........................................................................................ 15

6. Control Charts ..................................................................................................................... 16

6.1. Definitions ................................................................................................................. 16

6.2. Discussion ................................................................................................................. 17

6.3. Quality Control Sample Example ............................................................................... 18

6.4. References ................................................................................................................ 18

7. Statistics Applied to Drug Analysis ....................................................................................... 18

7.1. Introduction ............................................................................................................... 18

7.2. USP Guidance on Significant Figures and Rounding ................................................. 18

7.3. Additional Guidance in the USP ................................................................................ 19

7.4. References ................................................................................................................ 20

8. Statistics Applied to Radioactivity ........................................................................................ 21

8.1. Introduction ............................................................................................................... 21

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 2 of 29

For the most current and official copy, check QMiS.

8.2. Sample Counting ....................................................................................................... 21

8.3. Standard Deviation and Confidence Levels ............................................................... 22

8.4. Counting Rate and Activity ........................................................................................ 23

9. Statistics Applied to Biological Assays ................................................................................. 24

10. Statistics Applied to Microbiological Analysis ....................................................................... 25

10.1. Introduction ............................................................................................................... 25

10.2. Geometric Mean ........................................................................................................ 25

10.3. Most Probable Number .............................................................................................. 26

10.4. References ................................................................................................................ 27

11. Statistics Applied to pH in Canned Foods ............................................................................ 27

12. Rounding Guidelines Applied to Engineering Analyses ........................................................ 28

Document History ................................................................................................................ 29

Change History .................................................................................................................... 29

Attachments ......................................................................................................................... 29

1. Introduction

Statistics may be used in the ORS laboratory to describe and summarize the

results of sample analysis in a concise and mathematically meaningful way.

Statistics may also be used to predict properties (ingredients, acidity, quantity,

dissolution, height, weight, etc.) of a contaminant or of a regulated product

based on measurements made on a subset, or sample, of the contaminant or

product. All statistical concepts are ultimately based on mathematically

derived laws of probability. Understanding statistical concepts will allow the

ORS analyst to better convey analytical results with the maximum accuracy

and precision.

Proper application of statistics gives analysts the ability to report accurate

results, while allowing for the fact that there is inherent error (both random and

determinate) in virtually every laboratory measurement made.

This section is meant to be a general guide for situations commonly

encountered in the ORS laboratory. The section also gives guidance on

various aspects of data presentation and verification.

2. General Considerations

Statistical procedures used to describe measurements of samples in the ORS

laboratory allow regulatory decisions to be made in as unbiased manner as

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 3 of 29

For the most current and official copy, check QMiS.

possible. The following are numerically descriptive measures commonly used

in ORS laboratories.

2.1. Accuracy, Precision, and Uncertainty

A. Precision and accuracy are two essential factors related to uncertainty.

B. The accuracy of a measurement describes the difference between the

measured value and the true value or how well a measurement agrees

with the true or correct values. Accuracy is said to be high or low

depending on whether the measured value is near to, or distant from,

the true value.

C. Precision means how well each measurement agrees with each other,

regardless of the accuracy. Applied to an analytical method as used in

an ORS laboratory, a highly precise method is one in which repeated

application of the method on a sample will give results which agree

closely with one another. A series of measurements with high precision

will have low uncertainty and vice versa.

D. Improving precision (by reducing uncertainty) causes accuracy to be

increased.

E. All measurements have a degree of uncertainty regardless of precision

and accuracy. This is caused by two factors, the limitation of the

measuring instrument (systemic error) and the skill of the analyst

making the measurements (random error).

F. Terms such as accuracy, precision, and uncertainty are not

mathematically defined quantities but are useful concepts in

understanding the statistical treatment of data. Exact mathematical

expressions of accuracy and precision (error and deviation) will be

defined in the next section.

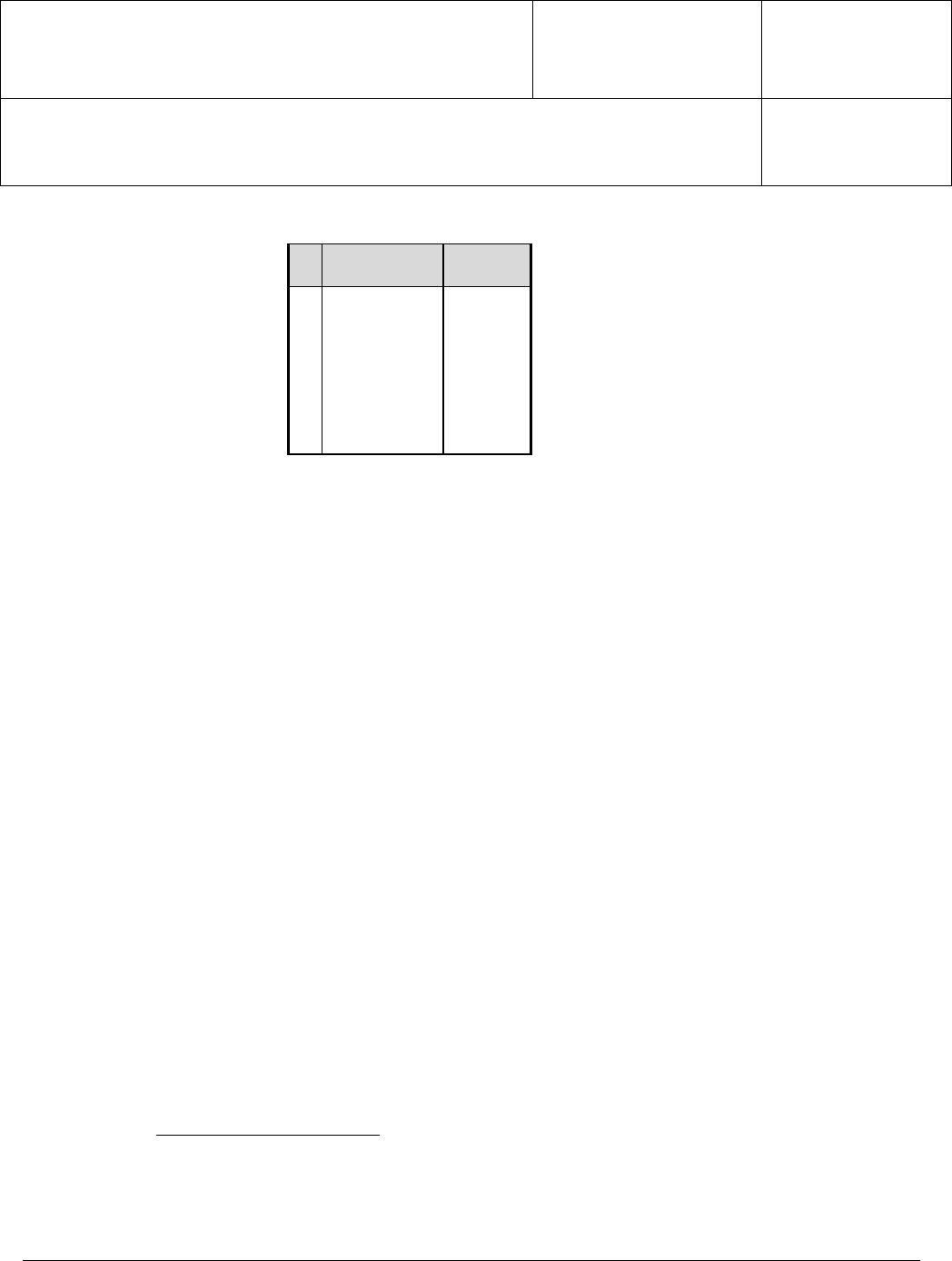

As an example of these terms, consider shooting arrows at a target,

where the “bull’s eye” is considered the true value. This picture

illustrates an important concept: accuracy and precision depend on the

bow, the arrow, and the archer.

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 4 of 29

For the most current and official copy, check QMiS.

An archer with low precision (high uncertainty) and low accuracy, will

produce a random pattern rather than clustered, with the bull’s eye

being hit only by chance.

With high precision (low uncertainty) but low accuracy a tightly clustered

pattern outside the bull’s eye occurs.

The best situation is high accuracy and high precision: in this case a

tight cluster is found in the bull’s eye area.

Applied to a laboratory procedure, this means that the reliability of

results depends on both the apparatus/instruments used and the

analyst. It is extremely important to have a well-trained analyst who

understands the method, applies it with care (for example by careful

weighing and dilution), and uses a calibrated instrument (demonstrated

to be operating reliably). Without all these components in place, it is

difficult to obtain the reliable results needed for regulatory analysis.

2.2. Error and Deviation; Mean and Standard Deviation

A. The concepts of accuracy and precision can be put on a mathematical

basis by defining equivalent terms: error and deviation. This will allow

the understanding of somewhat more complicated statistical

formulations used commonly in the ORS laboratory.

B. If a set of N replicate measurements x1, x2, x3, xn, were made

(examples: weighing a vial N times, determining HPLC peak area of N

injections from a single solution, measuring the height of a can N times,

…), then:

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 5 of 29

For the most current and official copy, check QMiS.

E

i

= x

i

– μ

where E

i

= error associated with measurement i,

x

i

= result of measurement i, and

μ = true value of measurement.

C. The definition of error often has little immediate practical application,

since in many cases μ, the true value, may not be known. However, the

process of calibration against a known value (such as a chemical or

physical standard) will help to minimize error by giving us a known value

with which to compare an unknown.

D. The deviation, a measure of precision, is calculated without reference to

the true value, but instead is related to the mean of a set of

measurements. The mean is defined by:

=

=

1

i

i

X

x

where

X

= mean of set of N measurements,

xi = i

th

measurement, and

N = Number of Measurements.

Note: this is the arithmetic mean of a set of observations. There are

other types of mean which can be calculated, such as the geometric

mean (see the section on “Application of Statistics to Microbiology”

below), which may be more accurate in special situations.

E. Then, the deviation, di, for each measurement is defined by:

d

i =

x

i

-

X

F. Using the example of the archer shooting arrows at a target, the

deviation for each arrow’s position is the distance from the arrow’s

position to the calculated mean of all the arrow’s positions.

G. Finally, the expression of deviation most useful in many ORS laboratory

applications is s, the standard deviation:

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 6 of 29

For the most current and official copy, check QMiS.

s =

1

1

2

d

−

=

N

N

i

i

=

( )

1

1

2

−

−

=

N

Xx

n

i

i

where s = standard deviation, and other terms are as previously

defined.

H. The standard deviation is then a measure of precision of a set of

measurements but has no relationship to the accuracy. The standard

deviation may also be expressed in relative terms, as the relative

standard deviation, or RSD:

RSD (%) =

X

s))(100(

I. Whereas the standard deviation has the same units as the

measurement, the RSD is dimensionless, and expressed as a

percentage of the mean.

Standard deviation as defined above is the correct choice when we

have a sample drawn from a larger population. This is almost always

the case in the ORS laboratory: the sample which has been collected is

assumed to be “representative” of the larger population (for example, a

batch of tablets, lot of canned goods, field of wheat) from which it has

been taken. As it is taken through analytical steps in the laboratory (by

subsampling, compositing, diluting, etc.) the representative

characteristic of the sample is maintained.

If the entire population is known for measurement, the standard

deviation s is redefined as σ, the population standard deviation. The

formula for σ differs from that of s in that (N-1) in the denominator is

replaced by N. The testing of an entire population would be a rare

circumstance in the ORS laboratory but may be useful in a research

project.

J. Statistical parameters such as mean and standard deviation are easily

calculated today using calculators and spreadsheet formulas. Although

this is convenient, the analyst should not forget how these parameters

are derived.

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 7 of 29

For the most current and official copy, check QMiS.

2.3. Random and Determinate Error

A. Recall the definition of error in Section 2.2 above. Errors in

measurement are often divided into two classes: determinate error and

non-determinate error. The latter is also termed random error. Both

types of error can arise from either the analyst or the instruments and

apparatus used, and both need to be minimized to obtain the best

measurement, that with the smallest error.

B. Determinate error is error that remains fixed throughout a set of

replicate measurements. Determinate error can often be corrected if it is

recognized. Examples include correcting titration results against a

blank, improving a chromatographic procedure so that a co-eluting peak

is separated from the peak of interest, or calibrating a balance against a

NIST-traceable standard. In fact, the purpose of most instrument

calibrations is to reduce or eliminate determinate error. Using the

example of the archer shooting arrows at a target, calibration of the

sights of the bow would decrease the error, leading to hitting the bull’s

eye.

C. Random error is error that varies from one measurement to another in

an unpredictable way in a set of measurements. Examples might

include variations in diluting to the mark during volumetric procedures,

fluctuations in an LC detector baseline over time, or placing an object to

be weighed at different positions on the balance pan. Random errors

are often a matter of analytical technique, and the experienced analyst,

who takes care in critical analytical operations, will usually obtain more

accurate results.

2.4. The Normal Distribution

A. In the introduction to this chapter, it was briefly mentioned that statistics

is derived from the mathematical theory of probability. This relationship

can be seen when we consider probability distribution functions, of

which the normal distribution function is an important example. The

normal distribution curve (or function) is of great value in aiding

understanding of measurement statistics, and to interpret results of

measurements. Although a detailed explanation is outside the scope of

this chapter, a brief explanation will be beneficial.

B. The normal distribution curve describes how the results of a set of

measurements are distributed as to frequency; assuming only random

errors are made. It describes the probability of obtaining a

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 8 of 29

For the most current and official copy, check QMiS.

measurement within a specified range of values. It is assumed here that

the values measured (i.e., variables) may vary continuously rather than

take on discrete values (the Poisson distribution, applicable to

radioactive decay is an example of a discrete probability distribution

function; see discussion under “Statistics Applied to Radioactivity”).

C. The normal distribution should be at least somewhat familiar to most

analysts as the “bell curve” or Gaussian curve. The curve can be

defined with just two statistical parameters that have been discussed:

the true value of the measured quantity, μ, and the true standard

deviation, σ. It is of the form:

Y =

e

x

2

/)(2/1

−−

Where Y= frequency of occurrence of a measurement (a value between

0 and 1),

x = the magnitude of the measurement,

μ = the true value of the measurement,

σ = true standard deviation of the population, and

e = base of natural logarithms (2.718…)

D. An example of two normal curves with the same true value, μ, but two

different values of σ is shown below (this was calculated using an

Excel® spreadsheet, using the formula above and an array of x values):

Normal Distribution

0

0.2

0.4

0.6

0.8

1

1.2

1 5 9 13 17 21 25 29 33 37 41 45 49 53 57 61 65 69 73 77 81 85 89 93 97 101

measurement (mean = 0.5)

Normalized frequency

standard

deviation =0.05

standard

deviation = 0.1

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 9 of 29

For the most current and official copy, check QMiS.

E. Some properties of the normal distribution curve that are evident by

inspection of the graph and mathematical function above go far in

explaining the properties of measurements in the laboratory:

1. In the absence of determinate errors, the measurement with the

most probable value will be the true value, μ.

2. Errors (i.e., x-μ), as defined previously, are distributed symmetrically

on either side of the true value, μ; errors greater than the mean are

equally as likely as errors below the mean.

3. Large errors are less likely to occur than small errors.

4. The curve never reaches the y-axis but approaches it asymptotically:

there is a finite probability of a measurement having any value.

5. The probability of a measurement being the true value increases as

the standard deviation decreases.

2.5. Confidence Intervals

A. The confidence interval of a measurement or set of measurements is

the range of values that the measurement may take with a stated level

of uncertainty. Although confidence intervals may be defined for any

probability distribution function, the normal distribution function

illustrates the concept well.

B. Approximately 68% of the area under the normal distribution curve is

included within ±1 standard deviation of the mean. This implies that, for

a series of replicate measurements, 68% will fall within ±1 standard

deviation of the true mean. Likewise, 95% of the area under the normal

distribution curve is found within about ± 2σ (to be precise, 1.96 σ), and

approximately 99.7% of the area of the curve is included within a range

of the mean ±3σ. A 95% confidence interval for a series of

measurements, therefore, is that which includes the mean ± 2σ. An

example of the application of confidence limits is in the preparation of

control charts, discussed in Section 6 below.

2.6. Populations and Samples: Student’s t Distribution

A. In the above discussion, we are using the true standard deviation, σ

(i.e., the population standard deviation). In most real-life situations, we

do not know the true value of σ. In the ORS laboratory, we are generally

working with a small sample which is assumed to be representative of

the population of interest (for example, a batch of tablets, a tanker of

milk). In this case, we can only calculate the sample standard deviation,

s, from a series of measurements. In this case, s is an estimate of σ,

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 10 of 29

For the most current and official copy, check QMiS.

and confidence limits need to be expanded by a factor, t, to account for

this additional uncertainty. The distribution of t is called the Student’s t

Distribution.

B. Further discussion is beyond the scope of this chapter, but tables of t

values, which depend on both the confidence limit desired and the

number of measurements made, are widely published.

2.7. References

The following are general references on statistics and treatment of data that

may be useful for the ORS Laboratory:

A. Dowdy, S., Wearden, S. (1991). Statistics for research (2nd ed.). New

York: John Wiley & Sons.

B. Garfield, F.M. (1991). Quality assurance principles for analytical

laboratories. Gaithersburg, MD: Association of Official Analytical

Chemists.

C. Taylor, J. K. (1985). Handbook for SRM users (NBS Special Publication

260-100). Gaithersburg, MD: National Institute for Standards and

Technology.

3. Data Handling and Presentation

In the most general sense, analytical work results in the generation of

numerical data. Operations such as weighing, diluting, etc. are common to

almost every analytical procedure, and the results of these operations,

together with instrumental outputs, are combined mathematically to obtain a

result or series of results. How these results are reported is important in

determining their significance. As a regulatory agency, it is important that we

report analytical results in a clear, unbiased manner that is truly reflective of

the operations that go into the result. Data should be reported with the proper

number of significant digits and rounded correctly. Procedures for

accomplishing this are given below:

3.1. Rounding of Reported Data

A. When a number is obtained by calculations, its accuracy depends on

the accuracy of the number used in the calculation. To limit numerical

errors, an extra significant figure is retained during calculations, and the

final answer rounded to the proper number of significant figures (see

next section for discussion of significant figures).

B. The following rules should be used:

1. If the extra digit is less than 5, drop the digit.

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 11 of 29

For the most current and official copy, check QMiS.

2. If the extra digit is greater than or equal to 5, drop it and increase the

previous digit by one.

C. Examples are given in the following table:

Calculated

Number

Significant

digits to report

Number with one

extra digit retained

Reported

rounded

number

79.35432

4

79.354

79.35

99.98798

5

99.9879

99.988

32.9653

4

32.965

32.97

32.9957

4

32.995

33.00

0.0396

1

0.039

0.04

105.67

3

105.6

106

29

2

29

29

3.2. Significant Figures

Significant figures (or significant digits) are used to express, in an approximate

way, the precision or uncertainty associated with a reported numerical result.

In a sense, this is the most general way to express “how well” a number is

known. The correct use of significant figures is important in today’s world,

where spreadsheets, handheld calculators, and instrumental digital readouts

can generate numbers to almost any degree of apparent precision, which may

be much different than the actual precision associated with a measurement. A

few simple rules will allow us to express results with the correct number of

significant figures or digits. The aim of these rules is to ensure that the final

result never contains any more significant figures than the least precise data

used to calculate it. This makes intuitive as well as scientific sense: a result is

only as good as the data that is used to calculate it (or more popularly,

“garbage in, garbage out”).

3.2.1. Definitions and Rules for Significant Figures

A. All non-zero digits are significant.

B. The most significant digit in a reported result is the left-most non-zero

digit: 359.741 (3 is the most significant digit).

C. If there is a decimal point, the least significant digit in a reported result is

the right-most digit (whether zero or not): 359.741 (1 is the least

significant digit). If there is no decimal point present, the right-most non-

zero digit is the least significant digit.

D. The number of digits between and including the most and least

significant digit is the number of significant digits in the result: 359.741

(there are six significant digits).

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 12 of 29

For the most current and official copy, check QMiS.

E. The following table gives examples of these definitions:

Number

Sig.

Digits

A

1.2345 g

5

B

12.3456 g

6

C

012.3 mg

3

D

12.3 mg

3

E

12.30 mg

4

F

12.030 mg

5

G

99.97 %

4

H

100.02 %

5

3.2.2. Significant Figures in Calculated Results

Most analytical results in ORS laboratories are obtained by arithmetic

combinations of numbers: addition, subtraction, multiplication, and division.

The proper number of digits used to express the result can be easily obtained

in all cases by remembering the principle stated above: numerical results are

reported with a precision near that of the least precise numerical measurement

used to generate the number. Some guidelines and examples follow.

3.2.2.1. Addition and Subtraction

The general guideline when adding and subtracting numbers is that the

answer should have decimal places equal to that of the component with the

least number of decimal places:

21.1

2.037

6.13

________

29.267 = 29.3, since component 21.1 has the least number of decimal places

3.2.2.2. Multiplication and Division

The general guideline is that the answer has the same number of significant

figures as the number with the fewest significant figures:

56 X 0.003462 X 43.72

1.684

A calculator yields an answer of 4.975740998 = 5.0, since one of the

measurements has only two significant figures.

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 13 of 29

For the most current and official copy, check QMiS.

4. Linear Curve Fitting

This section deals with fitting experimental data to a mathematical function.

This situation is encountered in a variety of situations in the ORS laboratory,

particularly with calibration curves. In most situations, the relationship between

the variables is linear, and therefore a linear function is needed:

y = f(x) = mx + b

Where x = independent variable,

y = dependent variable,

m = calculated slope of line, and

b = calculated y-intercept of line.

The independent variable, x, is assumed to be known exactly, with no error

(such as concentration, distance, time, etc.). The dependent variable, y,

(instrument response for example) then depends on (is a function of) the value

of x. Each value of the independent variable is assumed to follow a normal

distribution and to have the same variance (i.e., square of the standard

deviation). The method of linear regression (also known as linear least

squares) is used to fit experimental data to a linear function (note: in certain

cases, a non-linear relationship may be reduced to a linear equation by a

transformation of variables; if so, the linear regression method is still

applicable).

The aim of linear regression is to find the line which minimizes the sum of the

squares of the deviations of individual points from that line. Once that is

accomplished, the slope (m) and the intercept (b) of the ‘least squares’ line is

determined. It should be intuitively clear that minimizing deviations of data

points from the fitted line gives the best fit of data. Given a set of data points

(xi, yi), the equations used to determine the least squares parameters are:

SLOPE

= =

=

==

−

−

=

n

i

n

i

ii

n

i

n

i

i

n

i

iii

xxn

yxyxn

m

1

2

1

2

1

11

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 14 of 29

For the most current and official copy, check QMiS.

n

xmy

b

n

i

n

i

ii

−

=

= =1 1

=

XmY −

(intercept)

An additional parameter, which is an indicator of the “goodness of fit” of the

line to the data points, is the coefficient of determination. This coefficient

denotes the strength of the linear association between x and y. The coefficient,

r2, uses information on means and deviations of each data set to express

variation numerically. If the two data sets correspond perfectly or exhibits no

variation, a coefficient of 1 will be calculated. A coefficient of 0 indicates there

is no relationship or no explanation of variation between the two data sets.

Typically, for analytical work performed in the ORS laboratory, the coefficient

should be very close to 1 (for example 0.999). The formula for the coefficient of

determination is:

( )( )

( )

( )

2

1

2

−−

=

=

yx

n

i

ii

ssn

yyxx

r

where terms have been defined previously.

The following figure illustrates several points relating to linear least squares

curve fitting. Data was entered into an Excel® spreadsheet and the linear

least squares regression line calculated and plotted from the data. The vertical

lines indicate the distances (residuals) that are minimized to achieve the best

fit.

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 15 of 29

For the most current and official copy, check QMiS.

5. Development and Validation of Spreadsheets for Calculation of Data

When using spreadsheets or programmable calculators for reduction of data

generated by sample analyses, there should be assurance that the results are

valid and usable for regulatory use. The following section provides guidance

for assuring that spreadsheets will meet these criteria.

5.1. Introduction

Although the formulas given above for calculation of statistical parameters may

seem complicated, matters are simplified by the ready availability of

spreadsheets and calculators which provide these values transparently. This

makes calculation of statistical parameters much more straightforward than in

the past when direct application of these formulas was used. It is still useful to

have some familiarity with these formulas to understand how statistical

parameters are derived. In addition, there may be a need to verify the results

of statistical data generated by a spreadsheet or calculator; data can be

plugged directly into the formulas above to verify these results.

5.2. Development of Spreadsheets

Excel® and other spreadsheets incorporate all the statistical parameters

discussed, as well as many others. Although individual spreadsheet functions

can be considered as reliable, it is important to make sure that data is

presented to the spreadsheet with the proper syntax. Also, when spreadsheets

are used for multiple numerical calculations in the form of in-house developed

templates, it is important to protect the spreadsheet from inadvertent changes,

to verify the reliability of the spreadsheet by comparison with known results

from known data, and to ensure that the spreadsheet can handle unforeseen

data input needs. Spreadsheets developed in the ORS laboratory should be

looked upon as in-house developed software that are qualified before use, just

as instruments are qualified before use.

5.3. Validation of Spreadsheets

General guidance for design and validation of in-house spreadsheets and

other numerical calculation programs includes the following considerations:

A. Lock all cells of a spreadsheet, except those needed by the user to

input data.

B. Make spreadsheets read-only, with password protection, so that only

authorized users can alter the spreadsheet.

C. Design the spreadsheet so that data outside acceptable conditions is

rejected (for example, reject non-numerical inputs).

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 16 of 29

For the most current and official copy, check QMiS.

D. Verify spreadsheet calculations using a manual calculation method (i.e.,

calculator). Maintain a record of these calculations.

E. Enter data at extreme values, as well as at expected values, to assess

the ruggedness of the spreadsheet.

F. Test the spreadsheet by entering nonsensical data (for example

alphabetical inputs, <CTRL> sequences, etc.).

G. Keep a permanent record of all cell formulas when the spreadsheet is

first developed. Document all changes made later to the spreadsheet

(after it has been in use) and control using a system of revision

numbers with documentation.

H. Periodically re-validate spreadsheets. This should include verification of

cell formulas, a manual reverification of spreadsheet calculations, and

confirmation locked cells are still protected from change.

6. Control Charts

A control chart is a graph of test results with limits established in which the test

results are expected to fall when the instrument or analytical procedure is in a

state of “statistical control.” A procedure is under statistical control when

results consistently fall within established control limits. There are a variety of

uses of control charts other than identifying results that are out of control. A

chart will disclose trends and cycles which will allow real time analysis of data

and information for deciding if corrective action is needed to prevent an entire

analytical system from being in an out-of-control state. The use of control

charts is strongly encouraged in regulatory science.

6.1. Definitions

A. Central line: mean value using the average of baseline data points from

earlier determinations, usually a minimum of ten results, but preferably

twenty results as the more data points used the better your accuracy

will be.

B. Inner control limit: the mean value ± 2 standard deviations

C. Outer control limit: the mean value ± 3 standard deviation

D. Upper line (UCL): the upper control limit

E. Lower line (LCL): the lower control limit

F. Variation

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 17 of 29

For the most current and official copy, check QMiS.

When a process is stable and in control, as in the above example, you

see nothing but common cause variation. This results from the normal

operation of a system and is expected due to routine factors.

When a single data point fall outside of the control limits something

unusual has caused the system to become out of control or a special

cause variation. It indicates that it is very unlikely that data point is due

to noise, randomness, or chance.

6.2. Discussion

A. Control charts are frequently used for quality control purposes in the

laboratory. Control charts serve as a tool that determines if results

performed on a routine basis (e.g., quality control samples) are

acceptable for the intended purposes of the data.

B. The mean control chart consists of a horizontal central line and two

pairs of horizontal control limits lines. The central line defines the mean

value, the inner control limit (mean ± 2 standard deviations), and outer

control limit (mean ± 3 standard deviations). Results are plotted on the

y-axis (control value) against the x-axis variable (e.g., date, batch

number).

C. Results fall within the inner control limits 95% of the time. Results

falling outside the inner control limit serve as a warning that the results

may be biased. Results falling outside the outer control limit indicate

the results are biased and corrective action should be taken.

D. It is important to note that control charts can reveal problems even

when all the data points fall within the control limits. If the plot looks

non-random, with the points exhibiting a form of systemic behavior,

there may still be something wrong. For example, if there are eight

consecutive data points above or below the mean, it is statistically

unlikely to be due to chance.

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 18 of 29

For the most current and official copy, check QMiS.

6.3. Quality Control Sample Example

A. The control chart for a laboratory instrument often plots the results of

the calibration result (y-axis) against the date (x-axis).

B. Mean control chart:

1. Calculate the mean calibration value from the average of at least 10

data points

2. Calculate ±2 standard deviation, ± 3 standard deviation values

3. Draw horizontal lines above and below the mean value at ±2

deviations and the mean value ± 3 standard deviations

4. Plot calibration results against the date or batch number

5. Define corrective actions if the calibration results fall outside the

inner and outer control limits.

6.4. References

A. Pecsok, Shields, Cairns. (1986). Modern methods of analysis (2nd

Ed.). New York: John Wiley and Sons.

B. Steinmeyer, K. P. (1994). Mathematics review for health physics

technicians. Hebron, CT: Radiation Safety Associates Publications.

(Also 2nd Ed. in 1998.)

7. Statistics Applied to Drug Analysis

Chemists in ORS laboratories may have to analyze a wide range of human

and animal drugs in several different dosage forms and using differing

analytical methods. Statistical evaluation of the analytical results is important

for making regulatory decisions.

7.1. Introduction

Drug analysis, as well as most analysis performed in the ORS laboratory,

relies on the statistical concepts defined above. In addition, there are

references in the United States Pharmacopeia (USP) and other official

references with which the drug analyst should be familiar.

7.2. USP Guidance on Significant Figures and Rounding

Under GENERAL NOTICES, the USP has several references, either direct or

implied, to statistics, reporting of results and maintaining precision during an

analysis. The drug analyst should be thoroughly familiar with the “Significant

Figures and Tolerances” section of the USP. Highlights of this section are

summarized as follows:

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 19 of 29

For the most current and official copy, check QMiS.

A. Numerical limits specified in a monograph include the extremes of the

values and all values in between, but no values outside these limits.

This statement should be applied after proper rounding of numerical

results. If, for example, a properly rounded result is found to lie exactly

at the extreme of a limit (e.g., limits 98.0-102.0% of declared; found

102.03%, rounded to 102.0%) then the monograph limits are met. If the

result lies outside the numerical limits (e.g., 98.0-102.0% of declared;

found 102.05%, rounded to 102.1%), then the monograph limits are not

met.

B. Numerical result should be reported to the same number of decimal

places as the limit expression stated in the monograph. For example, if

limits are stated as 90.0-110.0% of declared, report results to 1 decimal

place (e.g., 98.3%, 101.8%), after applying USP rounding rules.

C. An explicit statement is made for titrimetric procedures: essentially all

factors, such as weights of analyte, should be measured with precision

commensurate with the equivalence statement given in the monograph.

Examples in the significant figures section above illustrate the

importance of this for all analytical work.

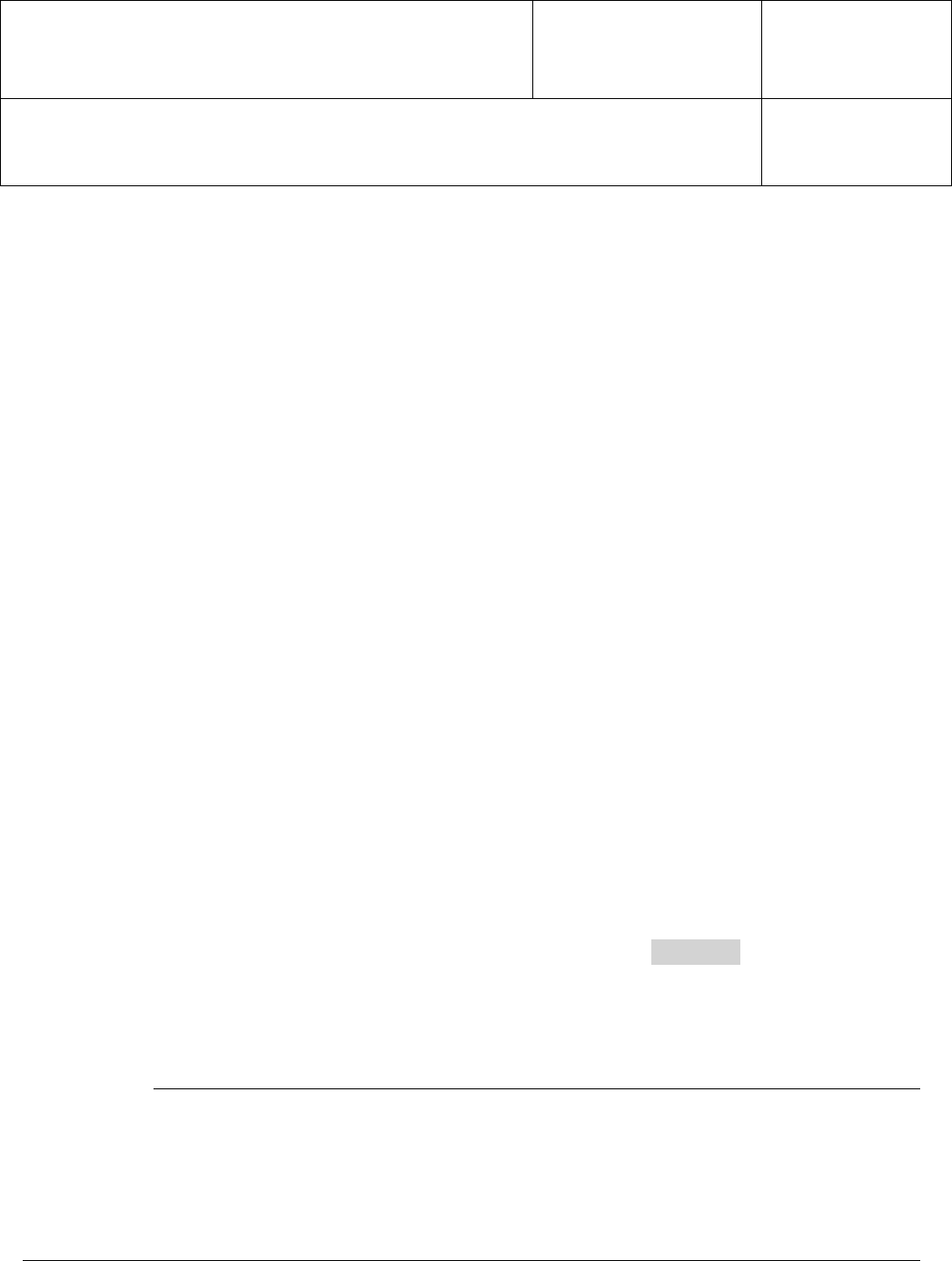

D. There is a table given in SIGNIFICANT FIGURES AND TOLERANCES

that gives examples of USP conventions for rounding, reporting, and

comparison of results with compendial limits. This should be reviewed

and thoroughly understood by all ORS drug analysts. A few additional

examples are given in the following table:

Compendial

Requirement

Unrounded

Result

Rounded

Result

Conforms?

(Y/N)

Assay not less than 95.0

And not more than 105.0%

of Declared

94.95%

95.0%

Y

94.94%

94.9%

N

105.65%

105.7%

N

Limit Test LTE 0.2%

0.24%

0.2%

Y

0.25%

0.3%

N

7.3. Additional Guidance in the USP

A. Under GENERAL NOTICES, TESTS AND ASSAYS, is additional

guidance. An important section is “Test Results, Statistics, and

Standards,” which is of regulatory significance. Important points to

understand include:

1. USP compendial instructions or guidelines are not to be applied

“statistically,” meaning the conformance or non-conformance of a

product is determined by a single test which may be applied to any

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 20 of 29

For the most current and official copy, check QMiS.

portion of a sample, at any time throughout its stated shelf life. The

monograph limits are chosen so that inherent uncertainty in the

method is considered, and system suitability tests verify that the

analytical system is reliable; therefore “any specimen tested as

directed in the monograph complies” (FDA’s practice, nonetheless,

is to perform a check analysis to confirm non-compliance with a

monograph limits).

2. To emphasize the “singlet determination” viewpoint of the USP, the

following statement is made: “Repeats, replicates, statistical

rejection of outliers, or extrapolations of results to larger populations

are neither specified nor proscribed by the compendia.”

B. Finally, under GENERAL NOTICES, TESTS AND ASSAYS, the

“Procedures” section includes some guidance that should be

understood by the ORS Laboratory drug analyst:

1. Weights and volumes of test substances and reference standards

may be adjusted proportionately, provided that such adjustments do

not adversely affect the accuracy of the procedure.

2. Similarly, when a method calls for a standardized solution of a

known concentration, a solution of a different concentration,

molarity, or normality may be used, provided allowance is made for

the differing concentration, and the error of measurement is not

thereby increased.

3. Monographs often use expressions such as “25.0 mL” for volumetric

measurements. This is not to be taken literally. In practice, volumes

used quantitatively (i.e., the measurement will be used in a

quantitative calculation) should be measured to the higher precision

specified in “Volumetric Apparatus <31>” of the USP. This generally

means that class A flasks, burets, and pipets are to be used, and

with proper analytical technique employed. Similarly, for weights:

“25.0 mg” means that the weighing should be performed with a high-

precision balance, meeting standards set forth in “Weights and

Balances <41>.”

7.4. References

(Current Ed.). U. S. Pharmacopeia and national formulary. Rockville, MD:

United States Pharmacopeial Convention, Inc.

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 21 of 29

For the most current and official copy, check QMiS.

8. Statistics Applied to Radioactivity

ORS laboratories may be involved in the identification and quantitative

measurement of radionuclides in foods, drugs, and the environment.

Instrumentation varies from simple counters to solid state detectors that

measure both discrete energy levels and the quantity of radiation in these

samples. The correct application of statistical principles is important for arriving

at the correct analytical result that will support regulatory decisions.

8.1. Introduction

Statistics is directly and intimately involved in measurements of radioactivity.

Whereas most measurements made in the ORS laboratory are based on

variables which vary continuously, radioactivity measurements are based on

the counting of discrete, random events. In this case, the normal distribution

probability function is replaced by the Poisson distribution, and the associated

statistical parameters (mean, standard deviation) are therefore expressed

differently.

8.2. Sample Counting

A. Radioactive decay is a random process that is described quantitatively

in statistical terms. Therefore, repeatedly counting radioactive

transformations in a sample under identical conditions will not

necessarily result in identical values. The result of counting sample

radiations is

s

Ncounts sampleof number =

B. The standard deviation of the sample counts, based on Poisson

statistics, is

ss

Ncounts sampleof deviation standard ==

C. Noise originating in the background, also a random process,

simultaneously generates counts that are indistinguishable from those

originating in the sample, and therefore the total or gross counts

observed from counting a sample include background counts,

bsg

NNNcounts samplegross +==

Where N

s

= sample counts and

N

b

= background counts

D. It follows that the counts due to sample radioactivity are obtained by

subtracting the background noise count from the sample gross counts

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 22 of 29

For the most current and official copy, check QMiS.

bgs

NNN −=

.

E. The counting rate due to sample radioactivity is

s

s

s

t

N

R =

where t

s

= sample counting interval

F. The sample counting rate can also be expressed as

b

b

g

g

bgs

t

N

t

N

RRR −=−=

Where:

rate counting samplegrossR

g

=

,

rate counting backgroundR

b

=

,

interval counting samplegrosst

g

=

, and

interval counting background t

b

=

.

8.3. Standard Deviation and Confidence Levels

A. The standard deviation is a measure of the dispersion of values of a

random variable about the mean value. For a large number of

measurements, 68 percent would be expected to lie within plus and

minus one standard deviation of the mean of the measurements; 96

percent would occur within plus or minus two standard deviations.

B. The standard deviation of the sample counting rate,

Rs

is given by:

b

b

g

g

RRR

t

R

t

R

bgs

+=+=

22

Where:

rate counting samplegross the of deviation standard

g

R

=

, and

rate counting background the of deviation standard

b

R

=

.

C. The sample rate plus or minus one standard deviation is reported as

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 23 of 29

For the most current and official copy, check QMiS.

b

b

g

g

sRs

t

R

t

R

RR

s

+=

D. If a measured value is reported within the limits of one standard

deviation, there is a 68 percent certainty, or 68 percent confidence level,

that the true value of the measured quantity is between the given limits.

In other words, there is a 68 percent certainty that the real value lies

within the limits. If the value is reported at the 96 percent confidence

level, the true value is within plus or minus two standard deviations of

the reported value. Several confidence levels are tabulated below:

Confidence

Level (%)

Number of

Standard

Deviations

(σ

s

)

90

1.645

95

1.960

96

2.0

99

2.58

Example. A sample counted for 100 seconds yields 2300 gross counts. The

background measured under identical conditions yields 100 counts in 10

seconds. Calculate the sample counting rate (counts per second) and the

standard deviation of the sample counting rate. Report the results at the 96%

confidence level.

cps 13cps 10-cps 23

s 10

counts 100

s 100

counts 2300

==−=

s

R

cps 2.1

10

13

100

23

=+=

s

R

cps 4.2 cps 13 =

s

R

8.4. Counting Rate and Activity

A. The sample counting rate is proportional to sample activity and may be

converted to radioactivity units using correction factors. These may

include detector efficiency in units of counts per disintegration, chemical

recovery fraction, fractional radiation yield, and others. The sample

activity may be obtained from the counting rate as follows:

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 24 of 29

For the most current and official copy, check QMiS.

Yrε

t

R

t

R

R

Yrε

R

activity sample

b

b

g

g

s

Rs

s

+

=

=

Where:

efficiency detector ε =

recovery chemical r =

yield radiation Y =

B. Example. A Sr-89 sample, counted using a detector having a 50% beta-

particle detection efficiency for Sr 89 (0.5 counts per Sr-89

disintegration which emits one beta particle per disintegration), yields

500 gross counts in 10 seconds. The background count was 100 counts

in 60 seconds. The chemical recovery of strontium was 86%. Report

the approximate activity in the sample at the 68% confidence level.

cps2.23.48cps

60

7.1

10

50

s 60

counts 100

s 10

counts 500

=+−=

s

Rs

R

Bq 2.54.112Bq

86.05.0

2.23.48

activity Sample =

=

where 1 Bq (Becquerel) = 1 disintegration/s.

9. Statistics Applied to Biological Assays

A. Biological assays are those carried out by dosing a biological test

system (such as a rat or mouse) with the substance to be determined

and measuring a response. An example is the USP monograph for

Menotropins. This biological extract contains Luteinizing Hormone (LH)

and Follicle Stimulating Hormone (FSH), which have effects on the

reproductive organs. The assay consists of dosing male (LH) and

female (FSH) rats with menotropins and observing the effects (weight)

on the seminal vesicles and ovaries respectively after a multiple day

incubation time.

B. Although this type of assay will rarely be encountered in the ORS

laboratory, biological assays are instructive in the statistical complexity

encountered when dealing with highly variable systems such as live

animals. The interpretation of results is complicated by the fact that the

total variance of a measurement includes a large variance due to the

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 25 of 29

For the most current and official copy, check QMiS.

biological component. The analyst may also encounter these assays

when on team inspections.

C. The subject of biological assays is addressed in General Chapter <111>

of the USP, “Design and Analysis of Biological Assays,” where an

extensive statistical treatment is developed, based on the Analysis of

Variance (ANOVA). This is also one of the rare instances in the USP

where rejection of “outlier data” is allowed, under strict statistical

justification. The interested reader is referred to <111> for further

information.

10. Statistics Applied to Microbiological Analysis

Several analyses used by ORS microbiologists call for the enumeration of

microorganisms by statistical means. Two commonly used procedures for

estimating the number of microorganisms in a product are the plate count and

the Most Probable Number (MPN) tube methods. To avoid fictitious impression

of precision and accuracy, only 2 significant figures are reported. Many

regulatory decisions pertaining to microbial contamination or time-temperature

abuse of food will be based upon the level of organism present.

10.1. Introduction

Many microbiological analyses involve the counting of discrete events, for

example plate and tube counts for microbial growth and isolated colonies. As

in the case for radioactivity, the situation is one of random, discrete, and

relatively improbable events (such as growth of a colony forming unit on an

agar plate), and Poisson statistics apply.

10.2. Geometric Mean

A. In microbiological assays, because of the techniques used and the fact

that biological systems are being measured, a variety of unique

statistical situations arise. When determining, for example, the number

of colony-forming units on a plate from many replicate inoculations, the

data often does not correspond to the expected normal distribution.

That is, if the frequency of a given number of colonies is plotted against

the observed number of colonies, a non-symmetrical frequency

distribution is observed (note that the normal distribution curve is

completely symmetrical, centered about the arithmetic mean). Instead,

the distribution is skewed or tailed at the higher end. This is attributed to

the fact that bacterial counts tend to favor lower counts and disfavor

extremely high counts. In this situation, the arithmetic mean is not the

best statistical indicator; instead, the geometric mean is most often

used:

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 26 of 29

For the most current and official copy, check QMiS.

n

n

i

ig

xx

/1

1

=

=

where xi are the individual counts, and

indicates that the product of

the observations is determined rather than the sum.

B. For example, the arithmetic mean of the individual observations 1, 2

and 3 is:

( )

3

321 ++

= 2

C. whereas the geometric mean of the same observations is:

( )

3/1

321 xx

= 1.8

D. Question: Why would one expect lower plate counts to be more

probable than higher counts, thus causing a skewed probability

distribution? Answer: As the number of counts on a plate rises, in other

words the density of colonies rises, an overcrowding error occurs from

individual colonies inhibiting the formation of other colonies nearby.

Another factor appears to be a “counting fatigue” error at high numbers,

where the analyst may not count accurately because of the large

numbers involved.

E. An alternative way to calculate the geometric mean, which can be easily

derived from the product expression above, is to add the logarithms of

individual counts rather than form the product of the counts themselves.

The geometric mean is then defined as:

=

=

n

x

antix

n

i

i

g

1

log

log

This formula is much easier for calculation purposes, particularly when

many observations are involved.

10.3. Most Probable Number

Another statistical concept unique to microbiological observations is that of

Most Probable Number (MPN). The Most Probable Number is a statistically

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 27 of 29

For the most current and official copy, check QMiS.

derived estimate of the presence of microorganisms based on the presence or

absence of growth in serially diluted samples. After an initial dilution, serial

dilutions of the sample are made (for example, 1:10, 1:100, and 1:1000) with

several replicate tubes (for example, 3 or 5) at each dilution. After incubation,

the presence or absence of growth in each tube is tabulated. The resulting

code (number of positive tubes) is compared with published tables to give the

most probable number of microorganisms per unit of original, undiluted

sample. Most probable number tables are published for various numbers of

tubes at several dilutions. The statistical derivation is beyond the scope of this

discussion but is based on Poisson counting statistics. Tables are published in

the Bacteriological Analytical Manual (BAM), the AOAC Official Methods of

Analysis, and General Chapter <61> of the USP.

10.4. References

A. (Current Ed.). “Microbiological Examination of Nonsterile Products

<61>,” U. S. Pharmacopeia and national formulary. Rockville, MD:

United States Pharmacopeial Convention, Inc.

B. Tomlinson, L. (Ed.). (1998). Bacteriological analytical manual (8th ed.,

Rev. A, in hardcopy) Washington DC: R. I. Merker, Ph.D., Office of

Special Research Skills, Center for Food Safety and Applied Nutrition,

U.S. Food & Drug Administration and the current version of the

Bacteriological Analytical Manual (BAM) found online.

11. Statistics Applied to pH in Canned Foods

A. pH is a logarithmic measure for the acidity of an aqueous solution.

Since pH represents the negative logarithm of a number, it is not

mathematically correct to calculate simple averages or other summary

statistics. Instead, the values should be converted to hydrogen ion

concentrations, averaged, and re-converted to pH values.

B. The following guidance is provided:

1. Convert each pH value to hydrogen-ion activity (H+), using the

equation:

Activity = 10-pH

In Excel, the formula is: =10^ (-pH number)

2. Calculate the mean of the activity values by adding the values and

dividing the sum by the total number of values. Calculate the

standard deviation also from the activity values.

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 28 of 29

For the most current and official copy, check QMiS.

3. Convert the calculated mean activity back to pH units, using the

equation:

pH = (-)(log10)(mean H+ activity). Also convert the standard

deviation to pH units.

In Excel, the formula is: = -LOG10(number)

C. When the pH values correspond closely, there is not a significant

difference between the mathematical mean and the logarithmic mean.

As the pH values spread further apart from each other, the difference

between the two means become more significant.

12. Rounding Guidelines Applied to Engineering Analyses

A. Most engineering analyses test devices for performance. Performance

testing involves determining conformance of test data with product

specifications.

B. Engineering analyses rely on the statistical concepts defined above.

Standards also provide guidance for using significant figures when

determining conformance to specifications.

C. When reporting direct measurements from an instrument, record all

digits that are known exactly plus one digit that can be estimated (e.g.,

between ruler lines). The number of significant digits read from a digital

display should be between 0.05 (expanded uncertainty) and 0.5

(expanded uncertainty) of the instrument.

D. Calculate results using the observed values as reported and round only

the final result. Follow the rounding procedures in Section 3.1. In

addition, when the digit beyond the last place to be retained is 5 and

non-zero digits are beyond this 5, increase the retained digit by 1.

E. Compare the rounded value to the specified tolerance limit to determine

conformance.

F. Refer to ASTM E29 Using Significant Digits in Test Data to Determine

Conformance with Specifications.

FOOD AND DRUG ADMINISTRATION

OFFICE OF REGULATORY AFFAIRS

Office of Regulatory Science

Document Number:

MAN-000048

Revision #: 03

Revised:

07 Oct 2022

Title:

ORA Lab Manual Vol. III Section 4 - Basic Statistics and Data Presentation (III-

04)

Page 29 of 29

For the most current and official copy, check QMiS.

Document History

Revision

#

Status*

(D, I, R)

Date

Author Name and Title

Approving Official Name

and Title

1.4

R

01/30/2013

LMEB

LMEB

02

R

08/13/2019

LMEB

LMEB

03

R

REFER TO

QMIS

LMEB

LMEB

* - D: Draft, I: Initial, R: Revision

Change History

Revision

#

Change

1.2

Contents – Document History added.

Section 4.3 – title corrected to Data Handling and Presentation.

Section 4.3.1. – number of significant digits to report changed to 1 for 0.0396.

Section 4.10.4 – removed date from BAM reference.

1.3

Section 4.4, fourth paragraph – corrected to coefficient of determination and revised.

1.4

Header – Division of Field Science changed to Office of Regulatory Science

4.11 – Section added

02

Updated formatting and hyperlinks; Added new section “Rounding Guidelines Applied

to Engineering Analyses”

03

Changed rounding instructions in 3.1 to align with all method sources and calculation

methods, such as USP and Excel. (Removed USP specific rounding instructions from 7.2 as

3.1 edit now matches requirements). Added more specific instructions for clarity to Sections

2.1, 5.3, and 6 (all additions are highlighted in grey)

Attachments

None