SAND2019-12009 O

Unlimited Release

FEDERAL RADIOLOGICAL

MONITORING AND ASSESSMENT CENTER

FRMAC FLY AWAY LABORATORY MANUAL

The Federal Manual for Performing Laboratory Analysis

during a Radiological Emergency

October, 2019

SAND2019-12009 O

Unlimited Release

FRMAC Fly Away Laboratory Manual ii

Prepared by

Sandia National Laboratories

Albuquerque, New Mexico 87185 and Livermore, California 94550

Sandia National Laboratories is a multimission laboratory managed and operated by National Technology & Engineering Solutions of Sandia,

LLC, a wholly owned subsidiary of Honeywell International Inc., for the U.S. Department of Energy’s National Nuclear Security Administration

under contract DE-NA0003525.

SAND2019-12009 O

Unlimited Release

FRMAC Fly Away Laboratory Manual iii

FRMAC Fly Away Laboratory Manual

Elliott J. Leonard

FRMAC Laboratory Analysis FAL Supervisor

Sandia National Laboratories

Albuquerque, NM

Phil Torretto

FRMAC Laboratory Analysis Working Group

Lawrence Livermore National Laboratory

Livermore, CA

Arthur Shanks Jr., Technical Chairman

FRMAC Laboratory Analysis Working Group

Sandia National Laboratories

Albuquerque, NM

This work was supported by the U.S. Department of Energy, National Nuclear Security Administration

Nevada Operations Office, under Contract No. DE-AC08-96NV11718.

FRMAC is an acronym for Federal Radiological Monitoring and Assessment Center.

SAND2019-12009 O

Unlimited Release

FRMAC Fly Away Laboratory Manual iv

DISCLAIMER

This report was prepared as an account of work sponsored by an agency of the United States Government.

Neither the United States Government nor any agency thereof, nor any of their employees, nor any of their

contractors, subcontractors or their employees, makes any warranty, express or implied, or assumes any

legal liability or responsibility for the accuracy, completeness, or any third party’s use or the results of such

use of any information, apparatus, product, or process disclosed, or represents that its use would not

infringe privately owned rights. Reference herein to any specific commercial product, process, or service by

trade name, trademark, manufacturer, or otherwise, does not necessarily constitute or imply its

endorsement, recommendation, or favoring by the United States Government or any agency thereof or its

contractors or subcontractors. The views and opinions of authors expressed herein do not necessarily state

or reflect those of the United States Government or any agency thereof.

AVAILABILITY

Available for sale to the public, in paper, from:

U.S. Department of Commerce

National Technical Information Service

5285 Port Royal Road

Springfield, VA 22161

phone: 800.553.6847

fax: 703.605.6900

email: [email protected]

online ordering: http://www.ntis.gov/ordering.htm

Available electronically at http://www.osti.gov/bridge

Available for a processing fee to U.S. Department of Energy

and its contractors, in paper, from:

U.S. Department of Energy

Office of Scientific and Technical Information

P.O. Box 62

Oak Ridge, TN 37831-0062

phone: 865.576.8401

fax: 865.576.5728

email: [email protected]

Also available at the FRMAC website,

https://www.nnss.gov/pages/programs/FRMAC/FRMAC_DocumentsManuals.html

SAND2019-12009 O

Unlimited Release

FRMAC Fly Away Laboratory Manual v

Preface

This manual was written for those personnel who respond to a radiological/nuclear incident that

will be called upon to provide proper analysis support. Overall, this manual provides general

guidance and some specific diagrams and forms. However, it is understood that site- and event-

specific operational decisions and procedures may need to be modified at the time of an

emergency event. This manual is intended to provide guidance for Fly Away Laboratory

personnel without limiting FRMAC’s ability to integrate the work with other partners or

stakeholders.

The NNSA/NSO has the overall responsibility for maintaining the master copy of all FRMAC

manuals. Please provide comments on this manual to:

U.S. Department of Energy

National Nuclear Security Administration

Nevada Site Office

Attn: FRMAC Program Manager

P.O. Box 98518

Las Vegas, Nevada 89193-8518

Acknowledgments

Creation of the FRMAC Fly Away Laboratory (FAL) Manual was a major undertaking to which

many people contributed. Special thanks go to Elliott Leonard Sean Fournier and Ken Sansone

of Sandia National Laboratories; Manuel Franco Jr. and Luis Valdivia of Apple One; Wendy

Pemberton of the Remote Sensing Laboratory; and Richard Bibby, Cynthia Conrado, Jay Dixon,

Mark Johnson and Phil Torretto of Lawrence Livermore National Laboratory who developed and

organized much of the material in this revision.

SAND2019-12009 O

Unlimited Release

FRMAC Fly Away Laboratory Manual vi

Acronyms and Abbreviations

ADC

Analog to Digital Converter

ALARA

As Low As Reasonably Achievable

ARF

Analysis Request Form

ARMS

Asset Readiness Management System

CM

Consequence Management

CMHT

Consequence Management Home Team

CMRT I

Consequence Management Response Team phase I

DOE

Department of Energy

DQO

Data Quality Objectives

EOTA

Emergency Operations Training Academy

FAL

Fly Away Laboratory

FRMAC

Federal Radiological Management Assessment Center

FWHM

Full Width at Half Maximum

GAB

Gross Alpha/Beta

HPGe

High Purity Germanium

HVPS

High Voltage Power Supply

ICS

Incident Command System

LAN

Local Area Network

LLD

Lower Level Discriminator

LSC

Liquid Scintillation Counting

MCA

Multi-Channel Analyzer

MQO

Measurement Quality Objectives

NIST

National Institute of Standards and Technology

NNSA

National Nuclear Security Administration

NSO

Nevada Site Office

QA

Quality Assurance

QC

Quality Control

RSL

Remote Sensing Laboratory

SCF

Sample Control Form

SNL

Sandia National Laboratories

SOP

Standard Operating Procedure

USB

Universal Serial Bus

SAND2019-12009 O

Unlimited Release

FRMAC Fly Away Laboratory Manual vii

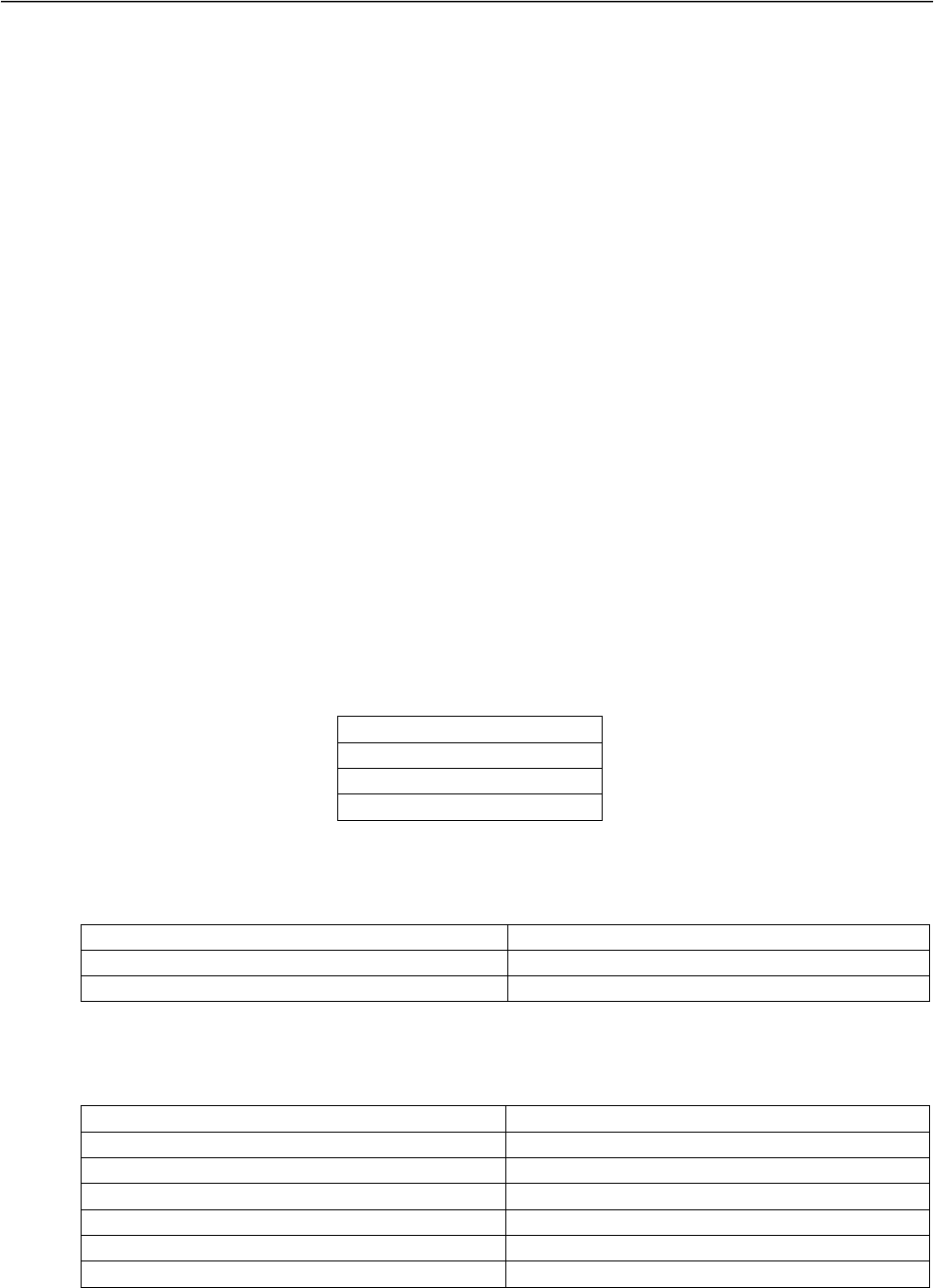

Table of Contents

Revision Date

Section 1. Introduction…………………………...............………………………………..

1-1

11/13

Section 2. Roles and Responsibilities......................................…………….....…….

2-1

11/13

Section 3. Quality Control..…………………………………………………….............….

3-1

8/19

Section 4. Sample Control................................................................…….....……….....

4-1

8/19

Section 5. Logistics................................................................…………………......……...

5-1

11/13

Section 6. Gamma Spectroscopy Procedures....……………………..........……….

6-1

8/19

Section 7. iSOLO Operations...........……………………………………............………

7-1

8/19

Section 8. Analytical Balance Use..............................................................................

8-1

11/13

Section 9. Data Handling and Verification/Validation...................................

9-1

11/13

List of Appendices

Appendix A: iSOCS Geometry Composer Tutorial...........……..…………….

A-1

11/13

Appendix B: Fly Away Laboratory Forms.……………………………..........…….

B-1

8/19

SAND2019-12009 O

Unlimited Release

FRMAC Fly Away Laboratory Manual viii

This page is intentionally left blank

August 2019 Section 1: Introduction

FRMAC Fly Away Laboratory Manual 1-1

Section 1: Introduction

When the FRMAC responds to a radiological/nuclear incident, monitoring, sampling, and

radioanalytical support will arrive from several different sources. The responders providing this

support will, likely, have received varying levels of training and will have experience with a

variety of monitoring, sampling, and radioanalytical equipment and procedures. It is important

that an acceptable and established set of standard operating procedures (SOPs) be followed by all

personnel having responsibilities for processing and analyzing samples during the emergency.

Overall, this manual provides general guidance and some specific diagrams and forms. However,

it is understood that site- and event-specific operational decisions and procedure parameters will

need to be established and documented at the time of an emergency.

The purpose of this manual is to provide guidance to Fly Away Laboratory (FAL) personnel

responsible for the analysis of time sensitive radiological samples. With proper training,

preparation, and equipment, FAL personnel will be able to quickly provide reliable results for

radiological samples that have been deemed immediately important to the health and safety of

emergency response personnel as well as the general public. Upon deployment of the FRMAC,

the Consequence Management Response Team will have set up shelter and workspace for the

FAL. Equipment load-outs have been designed to be able to be shipped via commercial airlines

or DOE aircraft. In this way, the FAL will most likely be the first field laboratory on-site and

will be crucial in the rapid analysis of emergency-phase samples.

It is the responsibility of CMRT personnel to deploy the laboratory specific-equipment and begin

operations upon arrival. This manual will provide guidance as to how to set up an efficient

laboratory working area. However, it will be up to the FAL personnel to be able to adapt to any

situation that may come up during an event. Although a part of the FRMAC, the FAL will be

acting as a laboratory entity with respect to the other FRMAC functions (Laboratory Analysis,

Assessment, Monitoring and Sampling, Health and Safety) and will take direct instruction from

the FAL Manager and FRMAC Laboratory Analysis personnel.

Work in the Fly Away Laboratory may require working outdoors in possibly extreme conditions.

Watch for snakes, rodents, insects, and other potentially hazardous flora or fauna. Be aware of

changing weather conditions, and immediately follow all orders regarding the protection of your

health and safety.

August 2019 Section 1: Introduction

FRMAC Fly Away Laboratory Manual 1-2

This page is intentionally left blank

August 2019 Section 2: Roles and Responsibilities

FRMAC Fly Away Laboratory Manual 2-1

Section 2: Roles and Responsibilities

Table of Contents

2.1 Position Descriptions ....................................................................................................................... 2

2.1.1 Fly Away Laboratory Manager .......................................................................................................... 2

2.1.2 Fly Away Laboratory Analst ............................................................................................................... 3

2.2 Required Training Matrix ................................................................................................................. 5

Tables

Table 2.1: FAL Personnel Training Requirements .................................................................................... 5

August 2019 Section 2: Roles and Responsibilities

FRMAC Fly Away Laboratory Manual 2-2

2.1 Position Descriptions

2.1.1 Fly Away Laboratory Manager

The FRMAC Fly Away Laboratory (FAL) Manager maintains close coordination with the

FMRAC Laboratory Analysis Manager. The FAL Manager communicates and interfaces with

FAL personnel to ensure that the FAL’s resources are adequately and correctly used.

Deploys in Phase I – No

Deploys in Phase II - Yes

2.1.1.1 Duties and Responsibilities

• Maintain a general working knowledge and understanding of FRMAC missions,

capabilities, objectives, and procedures

• Maintain expert working knowledge and experience in radiochemical analytical

methods, laboratory operations, laboratory QA/QC, and environmental

radiochemistry

• Maintain detailed knowledge, expertise, and proficiency with the FRMAC Fly Away

Laboratory Manual, laboratory sample tracking, and data analysis software

• Communicate sample priorities from the Laboratory Analysis Group to the FAL Staff

• Communicate analytical capability and capacity of the FAL to the FRMAC

Laboratory Analysis Manager and FRMAC Laboratory Analysis Deputy Manager

• Participate in calls, meetings, and conferences of the Laboratory Analysis Working

group during an active event

• Act as the final approval in the quality assurance data review process for all samples

analyzed by the FAL

2.1.1.2 Organization and Communications

• RECEIVES DIRECTION FROM:

o FRMAC Laboratory Analysis Manager

• WORKS WITH:

o FRMAC Laboratory Analysis Manager

o FRMAC Deputy Laboratory Analysis Manager

o FRMAC Laboratory Analysis Personnel

o FAL Laboratory Staff

• PROVIDES DIRECTION TO:

o FAL Laboratory Staff

2.1.1.3 Skills and Knowledge

• Maintain a general working knowledge and understanding of FRMAC missions,

capabilities, objectives, and procedures

• Maintain expert working knowledge and experience in radioanalytical methods,

laboratory operations, laboratory QA/QC, and environmental radiochemistry

August 2019 Section 2: Roles and Responsibilities

FRMAC Fly Away Laboratory Manual 2-3

• Demonstrated extensive knowledge and experience in laboratory and environmental

radiochemistry methods

• Working knowledge and experience with DQOs, analytical methods, minimum

detectable activity (MDA) calculations, and quality assurance procedures

• Working knowledge and experience with DRLs, AALs, EPA PAGs and FDA

intervention levels

• Radiation Worker I trained

• Successful completion of all training identified in Asset Readiness and Management

System (ARMS)

• Authorized for deployment

2.1.1.4 Education and Experience

• Active participation in an official FRMAC exercise as part of the FAL team

• Minimum of 3 years of experience managing a radioanalytical laboratory and

managing radioanalytical analyses

2.1.1.5 Physical Demands and Requirements

• Able to adapt and work in austere living conditions

• Able to work long hours in possibly stressful, urgent situations

• Able to adapt and work in extreme temperature and weather conditions

2.1.2 Fly Away Laboratory Analst

The FRMAC Fly Away Laboratory (FAL) Analyst is responsible for receiving, inspecting, and

logging in samples that have been submitted to, and screened by Health and Safety personnel.

The FAL Analyst place samples in the staging area and assists in preparing these samples for

analysis by completing the necessary documentation. Once documentation is complete, the FAL

Analyst places the samples into proper storage. The FAL Analysts are required to perform

requested analyses on samples received. This task includes sample preparation, detector setup,

sample counting, data analysis, and review.

Deploys in Phase I – No

Deploys in Phase II - Yes

2.1.2.1 Duties and Responsibilities

• Maintain a general working knowledge and understanding of FRMAC missions,

capabilities, objectives, and procedures

• Maintain detailed knowledge and familiarity with the FRMAC Fly Away Laboratory

Manual and sample control and data analysis software

• Review, validate, and sign chain of custody documentation (Analysis Request

Forms).

• Log samples into the FAL sample tracking system

• Record sample tracking information and prepare necessary paperwork

• Remain cognizant of contamination control procedures during all sample control and

handling activities

August 2019 Section 2: Roles and Responsibilities

FRMAC Fly Away Laboratory Manual 2-4

• Perform sample preparation

• Perform Gamma spectral analysis and detector efficiency modeling using vendor

software

• Perform liquid scintillation analysis

• Perform gross alpha/beta analysis

• Perform data report generation using custom software developed for the FAL

• Review laboratory results for errors

• Maintain instrumentation in working condition and calibration

• Perform routine quality control schedules for each instrument

• Troubleshoot hardware and software issues relevant to radiation detection

instrumentation

2.1.2.2 Organization and Communications

• RECEIVES DIRECTION FROM:

o FRMAC FAL Manager

• WORKS WITH:

o FRMAC Laboratory Analysis Personnel

o FRMAC FAL Manager

• PROVIDES DIRECTION TO:

o N/A

2.1.2.3 Skills and Knowledge

• Maintain a general working knowledge and understanding of FRMAC missions,

capabilities, objectives, and procedures

• Maintain working knowledge and experience in radioanalytical methods, laboratory

operations, laboratory QA/QC, and environmental radiochemistry.

• Demonstrated knowledge and experience in laboratory and environmental

radiochemistry

• Radiation Worker I trained

• Successful completion of all training identified in Asset Readiness and Management

System (ARMS)

• Authorized for deployment

2.1.2.4 EDUCATION AND EXPERIENCE

• Active participation in an official FRMAC exercise as part of the FAL team

• Minimum of 1 year experience performing analyses using Gamma Spectroscopy,

Alpha/Beta counting, or Liquid Scintillation counting, or has completed all of the

required training and works with a more experienced FAL Analyst

2.1.2.5 PHYSICAL DEMANDS AND REQUIREMENTS

• Able to adapt and work in austere living conditions

• Able to work long hours in possibly stressful, urgent situations

• Able to adapt and work in extreme temperature and weather conditions

August 2019 Section 2: Roles and Responsibilities

FRMAC Fly Away Laboratory Manual 2-5

2.2 Required Training Matrix

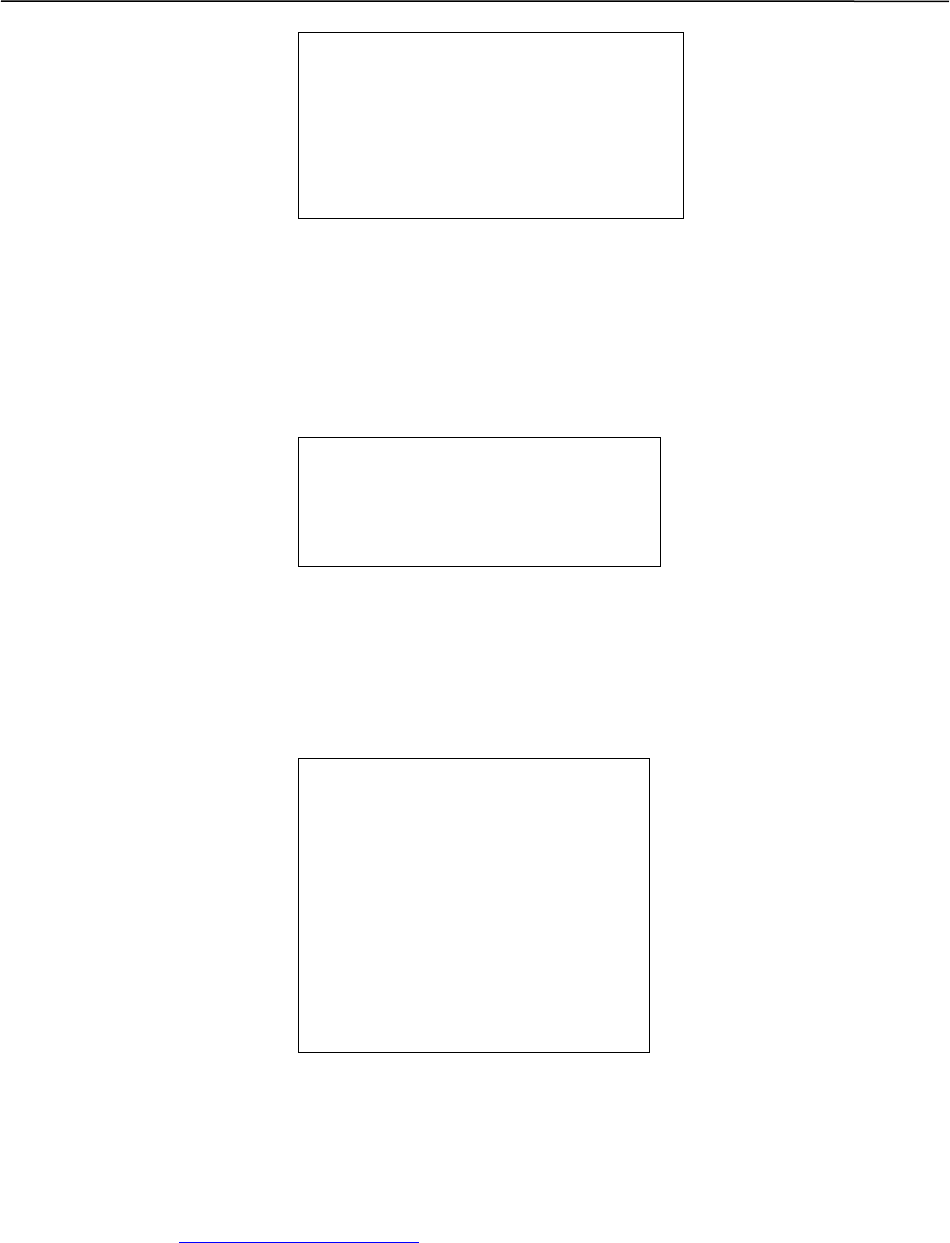

Table 2.1: FAL Personnel Training Requirements

Description

Frequency

Fly Away Lab

Manager

Laboratory

Staff

ICS 100- Introduction to ICS

1 time

X

X

ICS-200 – ICS for Single resources and Initial

Action Incidents

1 time

X

X

ICS-800.b National Response Framework

(NRF)Introduction.

1 time

X

X

DOE Rad Worker II (or equivalent)

Current

X

X

FAL -100 – FAL Field Logistics

3 yrs

X

X

FAL-200 – FAL Gamma Spectroscopy

Operations

3 yrs

X

X

FAL-300 – FAL Gross Alpha/Beta Operations

3 yrs

X

X

FAL-600 – FAL Gamma Spectrometer

Maintenance

3 yrs

X

FAL-700- FAL Gross Alpha/Beta Routine

Maintenance

3 yrs

X

August 2019 Section 2: Roles and Responsibilities

FRMAC Fly Away Laboratory Manual 2-6

This page is intentionally left blank

August 2019 Section 3: Quality Control

FRMAC Fly Away Laboratory Manual 3-1

Section 3: Quality Control

Table of Contents

3.1 Introduction ..................................................................................................................................... 2

3.2 QC Sample Assignment and Preparation ......................................................................................... 2

3.3 QC Sample Processing ...................................................................................................................... 2

3.3.1 Quality Control Samples .................................................................................................................... 2

3.3.2 Blank Samples ................................................................................................................................... 2

3.3.3 Laboratory Control Samples (LCS) ..................................................................................................... 3

August 2019 Section 3: Quality Control

FRMAC Fly Away Laboratory Manual 3-2

3.1 Introduction

The purpose of processing quality control (QC) samples is to provide continuing assurance of

laboratory performance and to make internal laboratory performance audits more effective.

Positive controls (laboratory control sample [LCS], blind quality control sample [BQC], and

matrix spike samples) serve as a monitor of the overall accuracy of all steps in the analysis,

including sample preparation. Negative controls (matrix blanks, backgrounds, and reagent

blanks) are used to assess the existence and magnitude of contamination problems as well as

natural background contributions. If problems with any QC sample exist, all data associated with

the batch shall be carefully evaluated to determine whether the sample results are adversely

affected.

Acceptance limits are predetermined and set in the software for each piece of instrumentation.

These values are set to typical acceptance limits for laboratory-grade instrumentation. However,

due to the variability in the environment, the Fly Away Laboratory Manager has the authority to

alter acceptance limits based on the situation.

3.2 QC Sample Assignment and Preparation

At a minimum, a set of QC samples should consist of one positive control and one negative

control. Assign a set of QC samples to each preparation batch of samples. The minimum number

of QC samples shall be one set included in each batch, where the batch does not exceed a total of

20 samples. If reasonable, positive controls should have activity concentrations appropriate for

the required measurement quality objectives (MQOs). Typically, LCS, BQCs, and/or matrix

spike sample concentrations should be at least 10 times the required critical level (L

c

) if possible.

3.3 QC Sample Processing

3.3.1 Quality Control Samples

QC samples serve as indicators of method performance. If the QC results fall outside of the

acceptance limits, all data associated with the batch shall be carefully evaluated to determine if

the samples were compromised, and appropriate corrective actions shall be taken. Reprocess any

samples that are suspected to be compromised. If reprocessing is not possible, contact the FAL

Manager. Reprocesses are documented in the case file associated with the group for samples in

question. Suspect results are qualified on the customer report. Instrument QC checks should be

performed routinely to ensure the instrument has not been contaminated and is operating within

control. Appropriate corrective actions (adjustments to the instrumentation, decontamination,

and/or recalibration) shall be performed if an instrument is determined to be operating outside of

tolerance limits. Record any corrective actions in the instrument’s logbook.

3.3.2 Blank Samples

Blank analysis results are assessed to determine the existence and magnitude of contamination

problems. The criteria for evaluation of blanks apply to any blank associated with the samples.

Review the results of the blanks. If the blank results fall outside the appropriate tolerance limits,

all data associated with the batch shall be carefully evaluated to determine whether the samples

were contaminated. Reprocess any samples that are suspected to be contaminated. If

August 2019 Section 3: Quality Control

FRMAC Fly Away Laboratory Manual 3-3

reprocessing is not possible, contact the FAL Manager. Document reprocesses in the batch file

associated with the group of samples in question. Qualify suspect results are on the customer

report.

3.3.3 Laboratory Control Samples (LCS)

The LCS serves as a monitor of the overall accuracy and performance of all steps in the analysis,

including the sample preparation. The LCS should contain an activity greater than 10 times the

radionuclide’s critical level, if possible. All LCS results should fall within the pre-established

tolerance limits, if applicable. If the LCS recoveries fall outside the appropriate tolerance limits,

all data associated with the batch shall be carefully evaluated to determine whether the actual

sample results were affected, and appropriate corrective actions shall be taken. Reprocess any

samples that are suspected to be affected. If reprocessing is not possible, contact the FAL

Manager.

August 2019 Section 3: Quality Control

FRMAC Fly Away Laboratory Manual 3-4

This page is intentionally left blank

August 2019 Section 4: Sample Control

FRMAC Fly Away Laboratory Manual 4-1

Section 4: Sample Control

Table of Contents

4.1 Introduction ..................................................................................................................................... 2

4.2 Setup of the Sample Control Staging Area ...................................................................................... 2

4.3 Sample Login and Tracking Process ................................................................................................. 3

4.3.1 Samples for Routine Analysis ............................................................................................................ 3

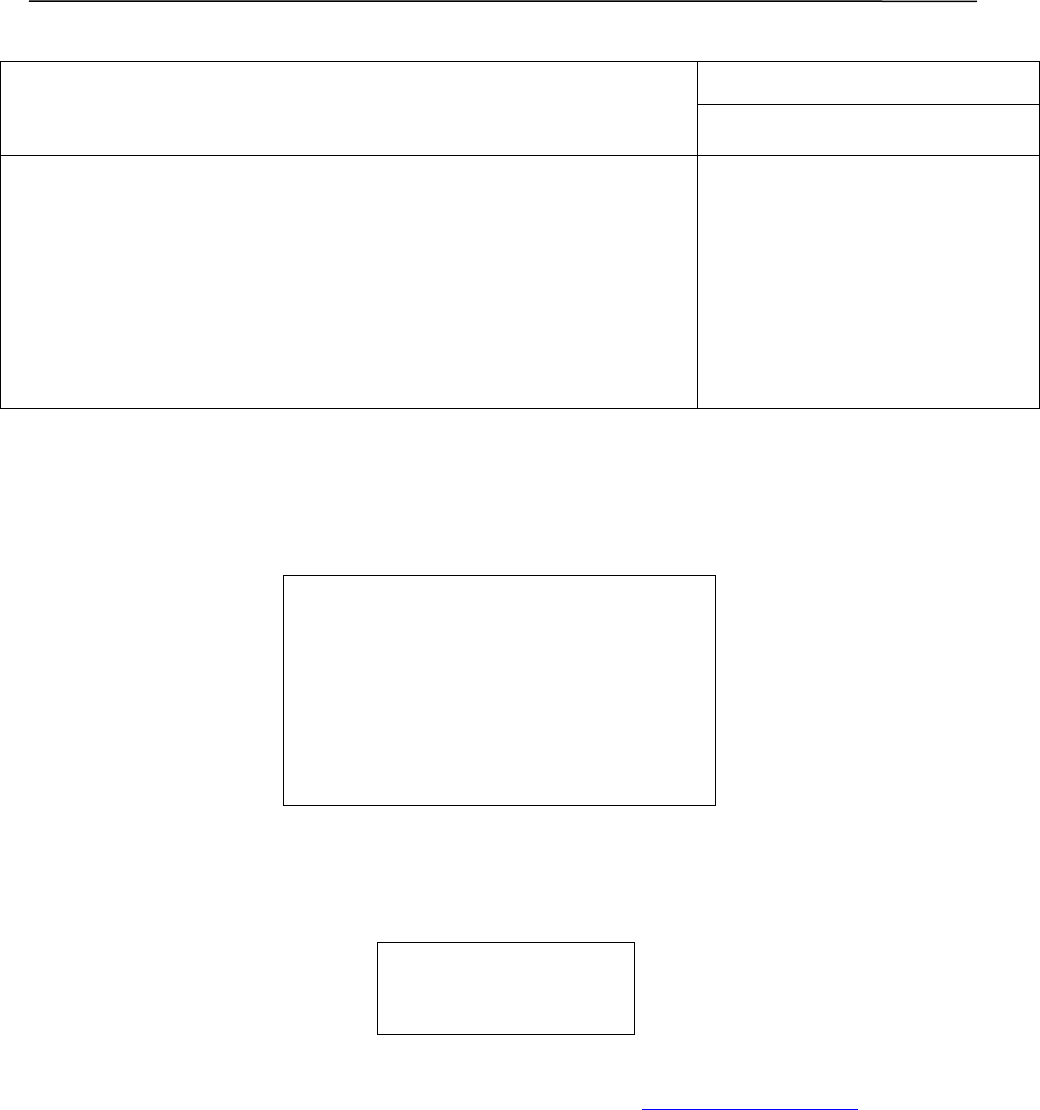

Figures

Figure 4.1: Example - Sample Control Staging Area Recommended Setup ............................................. 3

Figure 4.2: Tracking Database Main Menu .............................................................................................. 4

August 2019 Section 4: Sample Control

FRMAC Fly Away Laboratory Manual 4-2

4.1 Introduction

Upon deployment of the FRMAC Fly Away Laboratory, CMRT personnel will have deployed

the materials for an appropriate staging area. This section of the manual outlines the

recommended setup of the sample control area, where samples that are collected in the field will

be brought and logged into the FAL system. This section also outlines the logistical requirements

of the sample tracking process.

Sample tracking can be handled with the FAL Login excel spreadsheet. At the start of an event,

open the FAL LOGIN TEMPLATE.XLTM located on the sample login computer, or on the shire

FAL SharePoint. Fill out the header section Event Name and Start Date. Save the with the

filename that matches the event name.

4.2 Setup of the Sample Control Staging Area

There likely will be adequate tables and chairs to establish a sample control staging area onsite.

This area includes designated areas for temporary storage of samples received, a computer login

station, and areas for samples that require analysis, organized by the type of analysis requested .

The designated storage areas are marked off with tape and labeled with a marker.

Refer to Figure 4.1 for an example of the staging area layout.

Computer

Login

Station

Gamma

Spectroscopy

Samples

Gross

Alpha/Beta

Samples

Shipment

surveys

Completed

samples to

be returned

to FRMAC

August 2019 Section 4: Sample Control

FRMAC Fly Away Laboratory Manual 4-3

Figure 4.1: Example - Sample Control Staging Area Recommended Setup

It is recommended to set up the sample control staging area in such a way that it is clear which

samples have been logged into the system and are ready for analysis. All samples must be

processed through such a staging area before entering the laboratory area. When samples

contain significant quantities of radioactive material, be sure to align any staging or storage areas

to keep the dose to FAL personnel as low as reasonably achievable (ALARA) and ensure that the

instrument backgrounds are not affected by the flux of samples in and out of the storage area.

The use of temporary shielding or out-of-the-way storage areas may be required. Temporary

shield can be constructed using empty equipment boxes or coolers filled with water. You may

choose to request a radiological survey to be performed in this staging area by FRMAC Health

and Safety Radiological Control Technicians to be sure. You may also want to rerun

backgrounds on the FAL instrumentation when radiological conditions change in the

storage/staging area.

4.3 Sample Login and Tracking Process

4.3.1 Samples for Routine Analysis

Routinely, samples are brought by FRMAC Laboratory Analysis personnel to the Fly Away

Laboratory sample control staging area. Each group of samples has an Analysis Request Form

(ARF). This ARF includes all the required information to perform the analysis of the sample(s).

Each sample in a batch has a unique number associated with it, known as a “Sample Control

Form (SCF) or Sample number.” Upon receipt of a batch of samples, FAL Staff complete the

following:

1. The samples have been screened for external removable contamination at the hotline by a

FRMAC Radiation Control Technologist (RTC). If a breach in the contaminant is

suspected immediately contact FRMAC Heath and Safety for a contamination screening

and keep everyone in the area to avoid the spread of contamination.

3.

2. Confirm that all the samples listed on the ARF are included in the shipment to the staging

area.

4.

3. Have the courier of the samples sign the chain-of-custody line on the ARF indicating that

the samples are now leaving their possession.

5.

4. Sign the chain-of-custody line on the ARF indicating that you (FRMAC Fly Away

Laboratory) are now in custody of the samples. If the sample is contaminated, contact the

FAL Manager for guidance.

6.

5. Place the samples in the designated drop-off point.

7.

August 2019 Section 4: Sample Control

FRMAC Fly Away Laboratory Manual 4-4

6. Log the sample into the FAL login excel sheet created for the current event, as in Figure

4.2.

Figure 4.2: Tracking Database Main Menu

7. Enter the sample information by filling out the form:

• SCF number in the first column (A),

• ARF number in the second column (B),

• requested Analysis in the third column (C),

• sample matrix in the fourth column (D),

• place an “x” in the Pending Analysis column (E),

• select the priority in eight column (H),

• and optionally enter any pertinent comments in the ninth column (I).

8. The 10

th

Column (J) has controls to make entering the sample data easier. Double click

on the cell to perform the operation in that cell. For an ARF with many samples the COPY

ROW control followed by the excel fill down operation can be used in increase efficiency.

8.

9. Place each sample in the appropriate storage location next to the computer station. If the

samples are high activity samples, ask the FAL manager for further assistance. As

samples are picked up from the storage location, change the status of the sample in the

spreadsheet to “Pending Analysis” by placing an “x” in the Column E for that sample.

August 2019 Section 4: Sample Control

FRMAC Fly Away Laboratory Manual 4-5

9.

10. Upon completion of the analysis and review of the results, change the status of the

sample to “Reported” in by placing an “x” in the Column F for that sample. Place

completed samples in the “Return to FRMAC” location. When the courier arrives to pick

up samples, transfer the chain of custody of the samples back to FRMAC by signing the

appropriate chain of custody line on the ARF. Be sure to have the courier sign as

accepting possession of the sample(s). If possible, make a copy of the ARF, retain the

copy, and provide the original ARF to the courier.

10.

4.3.2 Samples for Non-routine Analysis

There is potential in the FAL to receive samples for shipping screening or from another

participating agency. Samples without an accompanying ARF fall within the scope of this

section. As such they will not have the typical chain of custody on the ARF nor the guarantee of

contamination and hazard screening.

1. Ensure that before receiving samples there has been a hazards screen for excess activity

on the sample and removable contamination. The results of the screen shall be

commutated to the FAL personnel in writing with the signature of the certified

Radiological Control Technician who performed the screening.

11.

2. Confirm that all the samples have a chain-of-custody (COC) and they are all listed on the

form.

12.

3. Have the courier of the samples sign the line the COC form indicating that the samples

are now leaving their possession.

13.

4. Sign the line the COC form (FRMAC Fly Away Laboratory) are now in custody of the

samples.

14.

5. Place the samples in the designated drop-off point.

6. Log the sample into the FAL login excel sheet created for the current event, as in Figure

4.2.

7. Enter the sample information by filling out the form:

• A unique identifying number either provided by the customer or if the sample is for

shipping screening number prepended with PRCL then a number in the first column

(A),

• A unique number grouping the samples or “Shipping” if the sample is for shipping

screening in the second column (B),

• requested Analysis in the third column (C),

• sample matrix in the fourth column (D),

• place an “x” in the Pending Analysis column (E),

• select the priority in eight column (H),

• and optionally enter any pertinent comments in the ninth column (I).

August 2019 Section 4: Sample Control

FRMAC Fly Away Laboratory Manual 4-6

8. The 10

th

Column (J) has controls to make entering the sample data easier. Double click

on the cell to perform the operation in that cell. For an ARF with many samples the COPY

ROW control followed by the excel fill down operation can be used in increase efficiency.

15.

9. Place each sample in the appropriate storage location next to the computer station. If the

samples are high activity samples, ask the FAL manager for further assistance. As

samples are picked up from the storage location, change the status of the sample in the

spreadsheet to “Pending Analysis” by placing an “x” in the Column E for that sample.

16.

10. Upon completion of the analysis and review of the results, change the status of the

sample to “Reported” in by placing an “x” in the Column F for that sample. Place

completed samples in the “Return to FRMAC” location. When the courier arrives to pick

up samples, transfer the chain of custody of the samples back to the customer by signing

the appropriate line on the COC. Be sure to have the courier sign as accepting possession

of the sample(s). If possible, make a copy of the COC, retain the copy, and provide the

original COC to the courier.

August 2019 Section 5: Logistics

FRMAC Fly Away Laboratory Manual 5-1

Section 5: Logistics

Table of Contents

5.1 Fly Away Laboratory Overview ........................................................................................................ 2

5.2 Equipment Load-Out ........................................................................................................................ 2

5.3 On-Site Equipment Needs ................................................................................................................ 2

5.4 Safety Hazards and Required Facility ............................................................................................... 3

5.5 Communication Requirements ........................................................................................................ 3

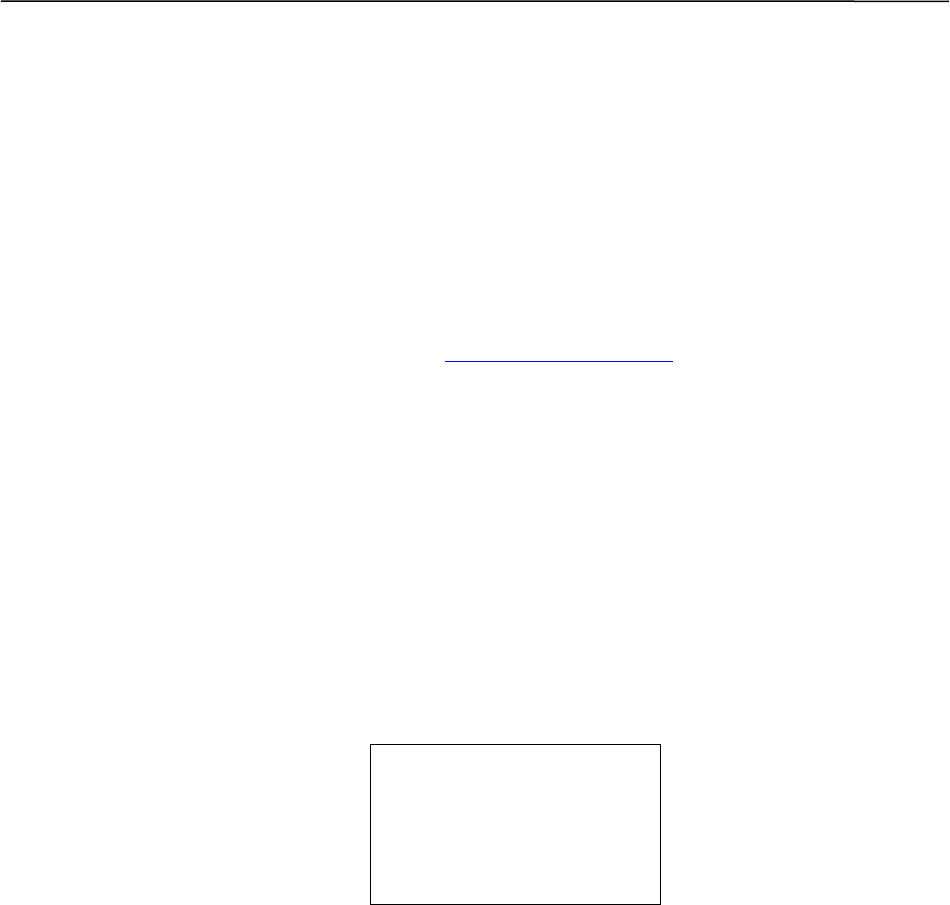

Figures

Figure 5.1: Fly Away Laboratory Floor Diagram ........................................................................................ 4

August 2019 Section 5: Logistics

FRMAC Fly Away Laboratory Manual 5-2

5.1 Fly Away Laboratory Overview

The DOE FAL is an asset capable of transporting its equipment via commercial, contract,

military, or charter aircraft. The laboratory equipment is located at the Remote Sensing

Laboratory (RSL) in Nevada and deployed as part of CMRT I. FAL personnel shall be

responsible for developing instrument capabilities, ensuring personnel are trained on the

calibration and use of the instrumentation, and ensuring that all equipment is available for

immediate deployment when called upon.

Deployed equipment is capable of analyzing samples for alpha-, beta- , and gamma-emitting

radionuclides.. They can process all types of samples including, but not limited to: ground

deposition, air filters, swipes, and liquid samples. However, no sample preparation capability is

available in the FAL and samples must be analyzed in the containers in which they are collected

except for air filters and smears which can be carefully removed from their container and placed

in the counting instrument.

.

The equipment is “exercised” regularly to ensure that the equipment is ready to be used on short

notice, and that personnel maintain training on the equipment.

Figure 5.1 provides an example layout of the Fly Away Laboratory processes. Due to the

proximity of the counting equipment, some analyses may be impacted by the samples submitted

to the FAL for analysis. For example, if a high activity sample is received for iSOLO analysis,

the background counts of the gamma spectroscopy units may be impacted. It is important to be

aware of this and make use of shielding and recounting of backgrounds to account for it.

5.2 Equipment Load-Out

If possible, a minimum of two of each of the following instruments will be maintained at the

RSL:

• Gamma Detector, Associated Computers, Software, Printers, and Standard Sources

• Radon Compensating Alpha/Beta Counter (iSOLO™), Associated Computer,

Software, Printers, and Standard Sources

NOTE: It is acceptable to have a single network printer for the entire Fly Away Laboratory.

5.3 On-Site Equipment Needs

The following are the on-site equipment needs:

• Six 6-ft tables

• Two 4-ft tables

• Six chairs

• Sample Storage containers

• Refrigeration capabilities (if required)

August 2019 Section 5: Logistics

FRMAC Fly Away Laboratory Manual 5-3

5.4 Safety Hazards and Required Facility

• Handling of radioactive sources and samples will be necessary. One should keep

radiation exposure as low as reasonably achievable (ALARA) by minimizing the

handling of sources and sample material. Care shall be exercised in handling samples

according to their associated hazards, whether they are a biological, chemical, and/or

radiological.

• When the potential for external contamination exists on the sample container(s),

protective gloves shall always be worn while handling the samples.

• The operation of a germanium detector requires a high voltage of 3 to 5 KV at a few

mA. Caution must be exercised to avoid touching any high voltage connections.

Much of the FAL equipment operates on Li-ion batteries. Inspect all batteries prior to

use for cracks, swelling, and signs of leakage. Dispose of damaged batteries

appropriately and replace with equivalent equipment.

•

• Work in the Fly Away Laboratory may require working outdoors in possibly extreme

conditions. Watch for snakes, rodents, insects, and other potentially hazardous flora

or fauna. Be aware of changing weather conditions and immediately follow all orders

regarding the protection of your health and safety. Care should be taken when lifting

heavy weights to avoid personal injuries.

• The following are facility requirements:

o Climate controlled 150 ft

2

lockable building/tent

o When not performing 24hr operations, a locked facility or security force is

required to protect the equipment when not in use.

o Sample storage area/tent (size dependent on the size of the incident)

o 110V power with a minimum of 12 outlets

o Generator fueled for 24 hour operations in the event of an extended power

outage

o Located near Sample Control Tent (desirable)

5.5 Communication Requirements

The following are the communication requirements:

• Email access to forward electronic results

• Internet access

• Wireless hotspot

• Telephone and fax line

August 2019 Section 5: Logistics

FRMAC Fly Away Laboratory Manual 5-4

Figure 5.1: Fly Away Laboratory Floor Diagram

Gamma Spec

Gamma Spec

iSolo Sample Screening

Work

Space

Work

Space

Sample

Holding

Area

iSolo

August 2019 Section 6: Gamma Spectroscopy Procedures

FRMAC Fly Away Laboratory Manual 6-1

Section 6: Gamma Spectroscopy Procedures

Table of Contents

6.1 Purpose ............................................................................................................................................ 3

6.2 Scope ................................................................................................................................................ 3

6.3 Summary of Method ........................................................................................................................ 3

6.4 Apparatus and Materials ................................................................................................................. 3

6.5 Routine Operations .......................................................................................................................... 4

6.5.1 On-site Setup of the FALCON™ ......................................................................................................... 4

6.5.2 Initializing the High Voltage .............................................................................................................. 7

6.5.3 Quality Control (QC) Check ............................................................................................................... 8

6.5.4 Performing a Background ................................................................................................................. 9

6.5.5 Gamma Library Creation ................................................................................................................. 10

6.5.6 Sample Analysis ............................................................................................................................... 11

6.5.7 Performing a Background Check (Blank) ......................................................................................... 14

6.5.3 ISOCS Check .................................................................................................................................... 15

6.6 Non-Routine Operations ................................................................................................................ 16

6.6.1 Calibration ....................................................................................................................................... 16

6.6.2 Initial Setup from Factory (New FALCON™ Unit) ............................................................................ 22

6.6.3 Acceptance Testing ......................................................................................................................... 38

Figures

Figure 6.1: FALCON 5000™ Power Setup .................................................................................................. 5

Figure 6.2: FALCON 5000™ Control/Display Panel ................................................................................... 5

Figure 6.3: FALCON 5000™ Battery ports and connectors....................................................................... 6

Figure 6.4: FALCON 5000™ Control/Display Panel ................................................................................... 6

Figure 6.6: Energy Calibration Curves Window Showing Peaks .............................................................. 18

Figure 6.7: Energy Calibration Curves Window Showing the Shape Curve ............................................ 18

Figure 6.8: Placement of Foam Spacers to Avoid Damage to Connector .............................................. 24

Figure 6.9: Access to the RS232 Port underneath the Display/Control Panel ....................................... 25

Figure 6.10: Example of the HyperTerminal .......................................................................................... 26

Figure 6.11: Example of the detector.txt File ......................................................................................... 37

Figure 6.12: Example of Data To Be Copied to detector.txt on the Machine ........................................ 38

August 2019 Section 6: Gamma Spectroscopy Procedures

FRMAC Fly Away Laboratory Manual 6-2

Tables

Table 6.1: Calibration Descriptions ........................................................................................................ 12

Table 6.2: Routine Analysis Required Sample Information.................................................................... 13

Table 6.3: Suggested Calibration Values ................................................................................................. 17

Table 6.4: FALCON 5000™ MCA Input Definition (MID) Settings Part 1 ................................................ 30

Table 6.5: FALCON 5000™ MCA Input Definition (MID) Settings Part 2 ................................................. 31

Table 6.6: QC QAF File Settings CNTRD and FWHM ............................................................................... 32

Table 6.7: QC QAF File Settings for DCA ................................................................................................. 33

Table 6.8: BKG QAF File Settings ............................................................................................................ 33

Table 6.9: ISX/LCS QAF File Settings ....................................................................................................... 33

Table 6.10: Required Executable Files ................................................................................................... 35

Table 6.11: Required CAM files .............................................................................................................. 35

Table 6.12: Required Template (.tpl) Files ............................................................................................. 35

Table 6.13: Required Calibration Files ................................................................................................... 36

Table 6.14: Example iSOCS™ Characterization Files .............................................................................. 37

August 2019 Section 6: Gamma Spectroscopy Procedures

FRMAC Fly Away Laboratory Manual 6-3

6.1 Purpose

The purpose of this procedure is to describe the proper use of the FALCON™ portable gamma

spectroscopy system. The following activities are documented in this procedure:

• On-Site Setup of the FALCON™

• Quality Control

• Sample Preparation

• Sample Analysis

• Calibration of the FALCON™

• Maintenance and Acceptance Testing

6.2 Scope

The FALCON™ 5000 is an electronically-cooled high purity germanium detector. This highly

mobile portable gamma spectrometer can rapidly provide nuclide identification and

quantification for gamma emitting isotopes in calibrated geometries. iSOCS™ calibration files

can be quickly and easily generated in the field for many geometries, freeing the user from the

requirement of having calibrated geometries prior to analysis. This capability allows for timely

and accurate analysis for almost any sample that may be collected in the field. The FALCON™

is an instrument that can provide accurate and timely information under demanding

circumstances.

6.3 Summary of Method

The FALCON™ 5000 can identify and quantify gamma emitting radionuclides of interest using

the established geometries and libraries. iSOCS™ can be used to accomplish similar tasks, but it

allows for more flexibility in the geometry. However, in analyses involving samples with a high

atomic mass, high density, and/or heavy materials, one must be aware of the attenuation effects

in the methodology and make appropriate considerations in the modeling.

6.4 Apparatus and Materials

• FALCON™ 5000 High Purity Germanium Gamma Spectroscopy System

• Laptop computer with Windows

• HyperTerminal program

• RS232 (serial) cable

• Radioactive mixed gamma sources

• External DC power supply

• Lithium-ion batteries

• Collimator

• Genie™ 2000 software

• FAL γ-RATS script and accompanying files

• Latex gloves or equivalent (i.e., Nitrile Gloves)

• In-Situ Object Calibration Software (iSOCS™)

August 2019 Section 6: Gamma Spectroscopy Procedures

FRMAC Fly Away Laboratory Manual 6-4

6.5 Routine Operations

6.5.1 On-site Setup of the FALCON™

Specific Required Equipment (Refer to FALCON™ Inventory List in ARMS):

• FALCON™ 5000

• Power Supply

• Power Cable (Power Supply to FALCON™)

• Computer

• Computer Power Supply

• LAN Cable

• FALCON™ Batteries (more than one may be required for this procedure).

Optional Equipment:

• Extension Cord

• Keyboard

• Mouse

• Printer

• USB Printer Cable

• Network Switch.

6.5.1.2 Setup of FALCON™ with Access to Electricity

1. Unpack the detector, accompanying power supply, batteries (2 per unit), and

associated cable.

a. Inspect the FALCON™ unit for any defects or missing parts.

b. Inspect the power supply for any damaged or frayed cords.

c. Inspect the batteries for damage, leakage, or corrosion.

1. Place the FALCON™ detector on a hard, flat surface or wooden base where you

intend to count samples. Situate the FALCON™ so that it is unlikely to get wet or

have excessive contact with dirt or other substances that may hinder effectiveness.

2. Place the power supply close to the FALCON™ in a location where it is unlikely to

get wet or excessively dirty or be in the line of sight between the detector crystal and

the sample. Attempt to keep the power supply a few feet away from any surge

protectors, transformers, or generators to avoid electronic interference with the

detector.

3. Ensure the power supply is set to the off position.

4. Attach the power supply to the FALCON™ with the gray power cable. This is the only

cable that fits in the appropriate holes. See Figure 6.1 below.

August 2019 Section 6: Gamma Spectroscopy Procedures

FRMAC Fly Away Laboratory Manual 6-5

Figure 6.1: FALCON 5000™ Power Setup

5. Attach the LAN cable from the FALCON™ to the computer.

6. If desired, attach mouse, keyboard, and printer to computer.

7. Plug both the FALCON™ power supply and computer power supply into a power

outlet.

8. Turn the FALCON™ power supply on.

9. Turn on the FALCON™ by pressing and holding the black button on the back panel of

the FALCON™ near the base.

10. The FALCON™ begins to cool itself electronically while in standby mode. This

process may take up to 4 hours.

11. There is a digital display on the top of the FALCON™ on the detector side. See Figure

6.2 below.

Figure 6.2: FALCON 5000™ Control/Display Panel

12. When the FALCON™ is not ready for use, a red light appears under the Temp High

label. When this light is on, the high voltage is locked out and the FALCON™ is

unable to operate. When the temperature has fallen to an acceptable range, the red light

goes out and a green light under the label Temp Normal lights up.

13. On the same panel as in the previous step, there is a large blue button

STANDBY/OPERATE. When turning the FALCON™ on, a yellow light is on next to the

label STANDBY. When the green temperature light is lit, hold the blue

STANDBY/OPERATE button for about 3 seconds, until the green light next to OPERATE

turns on.

14. The Green light under COMM LAN should be on; if not, check the cable on both ends

and make sure the tablet computer is on.

15. Continue to Section 6.5.2, Initializing the High Voltage.

August 2019 Section 6: Gamma Spectroscopy Procedures

FRMAC Fly Away Laboratory Manual 6-6

6.5.1.3 Setup of FALCON™ with Batteries

1. Place the FALCON™ detector on a hard, flat surface or wooden base where you

intend to count samples. Situate the FALCON™ so that it is unlikely to get wet or

have excessive contact with dirt or other substances that may hinder effectiveness.

2. Remove the battery panel, which is on the back of the FALCON™ near the top; it is a

black panel with four thumb screws. The FALCON™ should look as shown in Figure

6.3.

Figure 6.3: FALCON 5000™ Battery ports and connectors

3. Inspect the two batteries for any bulging, cracking, or leaking. Dispose and replace

damaged batteries appropriately.

4. Install the two batteries, one in each slot by sliding the battery into its slot and

plugging in the white clips. Replace the foam behind the batteries so that they do not

slide around.

5. Replace the cover and hand tighten the screws (do not use a screw driver).

6. Attach the LAN cable from the FALCON™ to the computer.

7. If desired, attach a mouse, keyboard, and printer to the computer.

8. Turn on the FALCON™ by pressing the black button on the back panel of the

FALCON™, near the base.

9. The FALCON™ takes about 4 hours to cool depending on the ambient temperature.

The batteries last less than 3 hours. A “hot swap” is required to complete the cool

down.

10. On the top of the detector near the front is a white panel. See Figure 6.4 below:

Figure 6.4: FALCON 5000™ Control/Display Panel

11. Watch the battery power level indicator. If the yellow light goes out and the red light

comes on, this indicates that the power level in the batteries is less than 25%. Remove

the battery cover.

August 2019 Section 6: Gamma Spectroscopy Procedures

FRMAC Fly Away Laboratory Manual 6-7

12. To perform a hot swap of the batteries, change out the batteries one at a time. If you

remove both batteries, the detector quickly heats back up, and you will have to

reinitiate the cooling process.

13. Replace the battery panel and hand tighten the screws.

14. When the FALCON™ is not ready for use, a red light appears under the Temp High

label. When this light is on, the high voltage is locked out and the FALCON™ is

unable to operate. When the temperature has fallen to an acceptable range, the red light

goes out and a green light under the label Temp Normal lights up.

15. On the same panel as in the previous step, there is a large blue button

STANDBY/OPERATE. When turning the FALCON™ on, a yellow light is on next to the

label STANDBY. When the green temperature light is lit, hold the blue

STANDBY/OPERATE button for about 3 seconds, until the green light next to OPERATE

turns on.

16. The green light under COMM LAN should be on; if not, check the cable on both ends

and make sure the tablet computer is on.

6.5.2 Initializing the High Voltage

1. At this point, the FALCON™ should be setup and cooled down to the operating

temperature. The green light next to the “Operate” label should be lit. If not, repeat the

above steps.

2. Open the folder “Genie 2000” on the Windows desktop.

3. Inside the Genie 2000 folder, double click on the “Gamma Acquisition and Analysis”

file.

4. Open the detector by going to FILE, and then select OPEN DATA SOURCE. This opens

a new window.

5. Near the center of the window are two radio buttons: file and detector. Click the

detector radio button. This will populate a list of detectors that have been installed on

this computer.

6. Select the appropriate detector (i.e., FAL03 or FAL05) and then click OPEN. If you

receive an error indicating that the required hardware is unavailable, a system reboot

of the computer and/or the detector may be necessary. Completely cycling the power

to the FALCON (pressing the button on the back of the unit, waiting 3-5 seconds and

pressing it on again) usually resolves this issue. If the problem persists, consult the

troubleshooting guide.

7. Near the top left of the screen, select MCA and then click ADJUST. This will open a

new window near the bottom of the screen.

8. Near the top of the new screen are several radio buttons. Select the HVPS (High

Voltage Power Supply) tab.

9. In the middle left of the window are two buttons under STATUS. Select the ON radio

button. In the top left of this window, a sign that says “Wait” appears. If the detector is

not defined on the system refer to the manufacturer’s detector sheet for the appropriate

voltage to apply.

10. Wait until this sign goes away; it will take between 10 and 30 seconds.

11. Place the QC source on the detector; refer to Section 6.5.3, Quality Control (QC)

Check, for instructions on how to place the source.

August 2019 Section 6: Gamma Spectroscopy Procedures

FRMAC Fly Away Laboratory Manual 6-8

12. To the left of the black screen in the Genie 2000 window are several buttons: START,

STOP, EXPAND and CLEAR. Press the START button.

13. The FALCON™ begins to acquire and display the spectrum on the screen. If desired,

click the EXPAND button, which opens a new screen above the main screen that

displays a zoomed-in portion of the spectrum. You can adjust the expanded view by

moving the white box that has appeared in the primary screen to move the zoomed

section left and right, and you can zoom in and out with the up and down arrow keys.

14. Ensure that the following is true:

o 1274.53 keV peak is approximately in channel 3480.

o 86.54 keV peak is approximately in channel 237.

15. If the peaks need adjusting, press STOP and then press CLEAR and wait about a minute

and try again by pressing START. If after 3 attempts the peaks do not appear where

they should, a gain adjustment may be needed. To adjust the gain navigate to MCA

and then click ADJUST. Click the GAIN radio button and adjust the gain until the peaks

fall in the correct channels. Seek guidance from the FAL Manager of assistance.

16. If the peaks are in their anticipated locations, close this window by clicking the X in

the top right of the screen. When a pop-up appears asking if you want to save your

changes, select NO.

17. Continue to Section 6.5.3, Quality Control (QC) Check.

6.5.3 Quality Control (QC) Check

A quality control check must be run at the beginning of a shift and at the end of a batch of

samples. If the case occurs that a batch spans a shift, the QC check must be run at the beginning

of the shift. A batch of samples comprises of up to 20 samples, including the quality control

check and background check.

1. Place the quality control source in the correct position, typically centered on the face

of the collimator or cover.

2. Launch the γ-RATS script if it is not already running.

3. Select the detector in the INPUT combo box if it is not already selected.

4. Select the DAILY QUALITY radio button in the COUNT TYPE section. The library,

geometry, background, count time, quantity, sample date and sample time should load

with the appropriate information. Do not change these parameters unless instructed to

do so by the FAL manager.

5. Enter your analyst initials in the ANALYST text box.

6. In the SAMPLE NUMBER text box enter Q[YY][MM][DD][N], where the bracketed

values are replaced with:

1. [YY] – 2-digit year

2. [MM] – 2-digit month

3. [DD] – 2-digit day

4. [N] – 1-digit indicating the number QC checks run that day

7. Press the COUNT button.

8. Next, the script procedure automatically clears the MCA, acquires a spectrum, and

analyzes and performs a peak centroid, efficiency, and FWHM check. The QA values

automatically update the specified Quality Assurance File (QAF). The quality

August 2019 Section 6: Gamma Spectroscopy Procedures

FRMAC Fly Away Laboratory Manual 6-9

assurance report is then sent to the Genie2K report review screen below the spectrum

view in a newly opened data source with the name that matches the sample number:

a. Review the spectrum to ensure that the expected peaks are present.

b. If no parameters are flagged on the report, the system is ready for use.

c. If any of the parameters of the quality assurance report fall outside the control

limits, another quality assurance measurement should be performed.

d. If the second count returns any parameter that falls outside the control limit, tag

the detector as out of service and investigate the problem. Record the instrument

as out of service in the instrument logbook. Consult the FAL manager to

determine the next appropriate action.

NOTE: If the error message “Detector not available” appears at this point, check to make sure

that the detector is not open in another application window. Also, make sure that the detector is

in the “operate” mode and the green LED light is on. If this still does not fix the problem,

perform the following steps:

a. Close the QC program.

b. Place the detector in standby mode.

c. Reset the VDM (Virtual Data Manager).

d. Place the detector in the “Operate” mode.

e. Restart the HVPS.

f. Restart the QC program.

Finally, if these steps do not work, power cycle the instrument by pressing the power button on

the back panel, waiting 3-5 seconds, and then pressing it again to power the instrument back on.

NOTE: Should the error “Too few points to perform test” appears, simply click OK and rerun

the QC measurement until there are enough points.

6.5.4 Performing a Background

During a response, radiological conditions (i.e., background) could change drastically from time

to time. It is very important to have a spectrum that characterizes the environmental background

when performing gamma spectroscopy. The Background measured in this section is used for

subtracting the ambient radiation and is verified by periodic blank measurements, See 6.5.7

Performing a Background Check (Blank). This requires measuring the background and entering

the results into a Quality Assurance File that the blank measurements can check against.

NOTE: This section shall be performed as part of the deployment setup of the Falcon.

NOTE: If the blank falls outside the prescribed limits, it is very important to take a new

background measurement. This includes geometries that require the collimator to be removed. In

such cases if the sample provides shielding count a blank sample matrix in the same geometry.

Perform this section for all geometries that deviate enough that the blank falls outside the

prescribed limits.

1. Launch the γ-RATS script if it is not already running.

2. Select the detector in the INPUT combo box if it is not already selected.

August 2019 Section 6: Gamma Spectroscopy Procedures

FRMAC Fly Away Laboratory Manual 6-10

3. Select the BACKGROUND radio button in the COUNT TYPE section. The library,

geometry, background, count time, quantity, sample date and sample time should load

with the appropriate information.

4. Enter your analyst initials in the ANALYST text box.

5. In the SAMPLE NUMBER text box enter B[YY][MM][DD][N], where the bracketed

values are replaced with:

a. [YY] – 2-digit year

b. [MM] – 2-digit month

c. [DD] – 2-digit day

d. [N] – 1-digit indicating the number QC checks run that day

6. Press the COUNT button.

7. Make a note of the filename, sample number, and count conditions present during the

background so the spectrum can be reused if necessary.

8. Wait for the count to finish.

9. When the analysis is complete, the file is saved with name in the format

[NN]_FAL_[YY][MM][DD] where the bracketed values are replaced with:

a. [YY] – 2-digit year

b. [MM] – 2-digit month

c. [DD] – 2-digit day

d. [NN] – 2-digit number of the Falcon.

During a routine analysis, you can choose this background to be subtracted from a

sample spectrum or select LATEST to use the latest. A report will print displaying the

total counts in three regions.

10. Open the Bkg.QAF file for the background in the Quality Assurance Editor

(C:\Genie2k\EXEFILES\qa.exe).

11. Select Edit-defs → Parameter Definitions… and press MORE…

12. Under the User Driven Tests (cps) enter the results from the background count found

on the report for the corresponding parameter in the MEAN text box.

13. Enter 10% of the Mean in the Std Dev text box.

14. Move to the next parameter by clicking in NEXT button.

15. Repeat steps 12-14 for all the parameters.

16. When finished, click OK to close the Full Parameter Edit window, and OK to Close

the Parameter Definition Edit window.

17. Select File → Save, then close the Quality Assurance Editor.

18. Record the background in the instrument logbook and take note of any non-routine or

special reasons why the background was collected.

6.5.5 Gamma Library Creation

The automatic electronic data deliverable (EDD) generator for the FALCON™ will force a

Region of Interest (ROI) and calculate an activity for every nuclide in the library independent of

whether the nuclide was detected or not. To avoid reporting undetected nuclides, a gamma

library should be created upon arrival that contains only the nuclides of interest for that event and

any others that happen to be detected on the sample.

August 2019 Section 6: Gamma Spectroscopy Procedures

FRMAC Fly Away Laboratory Manual 6-11

1. Determine the nuclides of interest by finding the requested nuclides on the Analysis

Request Form. It may be necessary to add nuclides as they appear in the spectra of

specific samples.

2. If necessary, open the “Genie 2000” program group by double clicking the icon.

3. Double click on the icon titled NUCLIDE LIBRARY EDITOR.

4. In the top section of the Nuclide Library Editor, enter the information into the fields

for the Nuclide Name (e.g. Co-60), Half-Life, and Uncertainty. Be sure the appropriate

radio button is selected for half-life units. Press the Add Nuclide button at the bottom

of the window and the information entered will appear in the lower section.

5. In the center section, enter the information into the Energy, Abundance, and

Uncertainty (left field is for energy uncertainty and the right field is for abundance

uncertainty) fields. Uncertainty is entered at 1-sigma. If the energy line is the most

abundant and does not interfere with any other nuclide lines, select the Key Line check

box. Press the Add Line button and the line will appear below the nuclide specified in

the top section.

6. If the nuclide has more gamma lines, overwrite the information in the center section

and press the Add Line button.

NOTE: Only one nuclide line can be the key line for a nuclide; this will appear as an asterisk in

front of the energy. The software will honor the last line added with the Key Line check box

checked.

NOTE: It may be easier to pare down an existing library than to create a new one. To do so,

open a large existing library and save as a new name. Begin removing nuclides by selecting them

in the lower section and pressing the Delete button. Save the file and close the Nuclide Library

Editor.

7. Check all the entries against a reputable source for accuracy and correctness. Due to

the tedious nature of library creation and the need for high accuracy, have another

FAL member check the entries.

8. Select SAVE AS command from the Nuclide Library Editor. In the FILE NAME field,

enter a meaningful name (e.g. the event name) for the library with the extension NLB.

In the DESCRIPTION field enter a meaningful description.

9. Click on the OK button to save the Library file. The Library file is saved in the

directory C:\genie2K\camfiles with the name given in Step 8 and the extension NLB.

It will now be available for use in Gamma RATS in the library drop-down menu.

6.5.6 Sample Analysis

1. Place the sample in the appropriate geometry that matches the calibrations or iSOCS

model on the machine.

2. Launch the γ-RATS script if it is not already running.

3. Select the detector in the INPUT combo box if it is not already selected.

4. Select the SAMPLE radio button in the COUNT TYPE section.

NOTE: The CUSTOM ASF can also be selected for an analysis that differs from the standard

analysis. Enter the sample type (CAM Parameter: STYPE) in the box and browse for the

Analysis Sequence File (ASF) to be used.

August 2019 Section 6: Gamma Spectroscopy Procedures

FRMAC Fly Away Laboratory Manual 6-12

5. Select Library (e.g., FRMAC.nlb).

6. Select a geometry (e.g., AF0AT3F). If no calibrated geometry is available, refer to

Appendix A of this manual to create an efficiency calibration using iSOCS™. Note

that a sample can be counted with a “dummy” calibration file and reanalyzed with the

proper mathematical efficiency model later. Table 6.1 describes commonly

encountered calibrations that are performed on the FALCON™.

7. Select the geometry accuracy radio button underneath the Geometries.

a. Select Regular if the sample exactly matches the calibrated geometry in matrix,

location, and size.

b. Select Similar if the sample is like the calibrated geometry in matrix, location, or

size. Note that this selection will apply a caveat to the analytical report stating

that the counting geometry was imprecise and could lead to biases in the results.

This option is to only be used when the deviation from the calibrated geometry is

minor. For example, if the calibrated geometry is one gallon of water in a

Cubitaner counted against the collimator face, but the sample is 0.95 gallons of

water in the same container and counted in the same location, the Similar option

should be used.

c. Select Irregular if the sample was not counted in a configuration that was

calibrated for or if the sample was not close to the calibration standard. This will

lead to a caveat on the report that states that the results are to be used as

identification only. Quantification is impossible when the sample was counted in

a configuration that was not calibrated for or modeled.

17.

Table 6.1 shows the common calibrations performed on the FALCON™ system.

Table 6.1: Calibration Descriptions

Calibration Name

Description

#AF2.CAL

2-inch glass fiber air filter on contact with collimator

cover

#CUB.CAL

1-Liter Cubitainer filled with water counted on the

collimator cover

#SGLD.CAL

Gladware container with approximately 500 grams of

soil counted on contact with the collimator cover with

the larger surface facing the detector. Typically used for

ground deposition samples.

#AFCC.CAL

2-inch face loaded charcoal cartridge counted with the

inlet side on contact with the collimator cover.

Suffix

Description

AT1FT

Sample was counted exactly 1 foot and on axis with the

detector collimator face. Typically used for samples that

cause dead time to exceed 10% when on contact.

AT3FT

Sample was counted exactly 3 feet and on axis with the

detector collimator face. Typically used for samples that

cause dead time to exceed 10% when at 1 ft.

August 2019 Section 6: Gamma Spectroscopy Procedures

FRMAC Fly Away Laboratory Manual 6-13

NOTE: # denotes the detector number that the calibration applies to.

8. Background Subtraction:

a. Uncheck the box if a background has not yet been run. If one has not been run

yet, the background can be subtracted later in a reanalysis of the spectrum.

b. If a background has been run and analyzed, place a check in the SUBTRACT BKG

box.

c. Choose the background count that most closely characterizes the environmental

radiation levels at the time of sample acquisition. “Latest” will find the last run

background. Check the instrument logbook for information regarding the

backgrounds. If there is any doubt as to what background to use, or if a new

background should be run, consult the FAL manager.

NOTE: In most portable count situations, the acquisition time for the background should be set

to the same acquisition time or longer as the sample for which the background analyses will be

applied. However, the software will make time corrections if the count times differ.

NOTE: In practice, the environmental background is taken prior to sample analysis. While this

is possible in most situations, samples may need to be counted prior to the determination of

background. This is acceptable if it can be shown that the environmental levels of radiation had

not changed between the sample measurement and the background measurement. The sample

spectrum must be reanalyzed with the most applicable background. If the detector is moved, a

new background must be taken. Record any detector movements or changes in the radiological

environment in the instrument logbook.

9. Enter count time for the analysis in seconds. The minimum count time is determined

by the FAL manager. This is done using the required critical level which is indicated

on the ARF. Or the required count time indicated on the ARF.

10. Enter your analyst initials in the ANALYST text box.

11. In the SAMPLE NUMBER text box enter the SCF identification number (e.g., SCF-

0001).

12. Enter the sample quantity and select the appropriate units. Ensure that the selected unit

matches the units from the requested critical level.

13. Enter or select the Sample Date (i.e., the date to which the nuclides will be decay

corrected) and the sample time in a 24-hour format (hh:mm).

14. Once data acquisition is complete, the spectrum is analyzed, and a detailed report is

generated along with an electronic comma separated variable (csv) file.

15. Carefully review the analysis report for mistakes or problems with the data. Sign and

date the “Analyzed by” line on the report.

16. Have the report reviewed a second time by another FAL staff that is trained in gamma

spectroscopy.

17. Import the .csv file into excel and enter the remaining information. The information is

outlined in Table 6.2

Table 6.2: Routine Analysis Required Sample Information

FALCON™ Sample Input Parameters

August 2019 Section 6: Gamma Spectroscopy Procedures

FRMAC Fly Away Laboratory Manual 6-14

Analysis Request #

This must match the tracking number on the analysis request form (e.g. ARF-

00002)

QC Batch ID

ARF numbering appended with a letter (e.g. ARF-0005-A)

Sample Matrix

Pull Down (Air Filter, Feed, Food, Instrument, Milk, Moving Air Filter,

Moving Instrument, Other, Soil Swipe, Vegetation, Water) – match what is

written on the ARF

Moisture Property

*only applies to soils. If the soil was dried in a laboratory and the mass

entered was the dry mass, select dry. If the sample was not dried and the wet

mass was used as the aliquot, select wet. For matrices other than soil, or if no

soil mass was used as the aliquot, select N/A.

18.

Samples that are analyzed by the FAL gamma spectrometer can be reanalyzed with different

efficiency files, libraries, backgrounds, etc. at any time.

18. Launch the γ-RATS script if it is not already running.