Basic Standards for

Home/Commercial Kitchens

and Small Scale Food

Processing Facilities

Prepared By:

NYS Department of Agriculture and Markets

Division of Food Safety and Inspection

Agenda

Regulations

Zoning/Jusidication - Licensing and exemptions

Specialized processing (HACCP)

Acidified foods, Juice, Seafood, Low acid canned foods

Overview of CURRENT GMPs

Labeling

Allergens

Food recalls

Employee training opportunities

Scheduled processes/authorities

FSMA

Resources

Regulations – Why do we have them?

The Federal government, individual states, cities and municipalities govern the operation of

food processing facilities whether home kitchens or commercial facilities.

When considering starting up a home or commercial kitchen, it is important to research the

following:

Which agencies regulates/licenses your product,

Foods allowed and not allowed to be produced in each facility,

Local zoning laws governing the use of the building

Foods that are regulated and require a Article 20-C Food Processing License in New York

This regulation applies to anything that is altered by value-added processing including

but not limited to: baking, blending, brewing, curing, fermenting, freezing, grinding,

pickling, canning, preserving, dehydrating, juicing, cider making, pickling, brining,

bottling, packaging, repackaging, vacuum or reduced oxygen packaging, pressing,

heating or cooking, smoking, roasting, or manufacturing.

Complete list in handout

Zoning Regulations? – Jurisdiction?

Procedure

Home Kitchen Home Annex (if licensable) Commercial

Inspection

No, Potable water required (documented)

–

municipal or treated well water

Yes, Potable water required (documented)

–

municipal or treated well water

Yes, Potable water required (documented) –

municipal or treated well water

Licensing

Non

-potentially hazardous foods exempt from

licensing by

NYS Department of Agriculture &

Markets (NYSDAM)

Wholesale or retail is allowed at agricultural venues

(farmers markets, craft fairs, etc.)

20

-C license

NYS Dept. of Agriculture &Markets

Separate cleaning, sanitizing, and hand wash

facilities.

Easily cleanable walls, floor, and ceiling.

Fee: $400.00/2 years

20

-C license

NYSDAM

Fee

– $400.00/2 years

Inspection Agency

NYSDAM

May request review of processing procedures by

recognized processing authority. Only normal

kitchen facilities can be used.

NYSDAM

NYSDAM

Food service facilities are inspected by the

Department of Health.

Foods Allowed

Candy

- non-chocolate, fudge

Cakes not requiring refrigeration

Cookies

Brownies

Double crust

fruit pies

Breads

(Not containing Fruit/Vegetables)

Rolls

Fruit jams, jellies

Spices, herbs (blending commercially dried)

Snack items

Baked goods (i.e. bread, rolls) for wholesale

distribution or retail at farmers markets, craft fairs,

etc.

Any processed food

Process Review required for any shelf stable foods.

May be required for other foods as well (i.e.

fermented)

Scheduled Process is required for Low acid and

acidified foods packed in hermetically sealed

containers.

Must register and file with FDA

Any processed food

Process Review required for any shelf stable

foods. May be required for other foods as

well (i.e. fermented)

Scheduled Process is required for Low acid

and acidified foods packed in hermetically

sealed containers.

Must register and file

with

FDA

Foods Not Allowed

Cakes which require refrigeration

Pies containing milk, eggs or meat products

Chocolates

Low acid / acidified foods

Etc.

Meat products

– if more than 3% raw or 2% cooked

meat ingredients

– USDA regulated

Meat products

if more than 3% raw or 2%

cooked meat ingredients

– USDA regulated

Zoning

Check with city/town Zoning /Planning Board

Issues: Scale of operation, number of employees

Check with municipality Zoning/Planning Board

Issues: scale of operation; number of employees

2nd kitchen may not be allowed on premise

Check with municipality Zoning/Planning

Board

Issues: scale of operation, number of

employees

Covered in

handout!

Home Processing Exemption

New York State allows non-hazardous foods such as candy, cakes not requiring refrigeration, cookies,

brownies, double crusted fruit pies, breads and rolls, standard fruit jams and jellies, repackaging

commercially dried spices and herbs, and snack items to be produced in home kitchens.

A review of processing procedures may be required for certain products before exemption is granted.

Anyone seeking a Home Processing Exemption must contact the NYS Department of Agriculture &

Markets. Home Processor information can be found on our website:

https://www.agriculture.ny.gov/FS/consumer/FSI-898D_Home_Processor.pdf Any questions can be

emailed to agr.sm.hpregistrations@agriculture.ny.gov

NOTE: An annual potable water test for bacteria is required for all home processors on private water

supplies. Internet sales are not allowed under this exemption.

Some types of foods may not be produced in a home kitchen, as mandated by Federal regulations.

These foods include :

Low acid and acidified (pickled) foods packed in hermetically sealed containers must be registered

with the US Food and Drug Administration (FDA).

Meat products with more than 3% raw or 2% cooked meat ingredients in a completed product are

regulated by the US Department of Agriculture (USDA).

Vacuum packaged and any other reduced oxygen packaged products.

20-C License Process –

License

Received

License

Reviewed

GMP

Inspection

License

Issued

License

renewed

every 2

years

Facility

inspection

frequency

is based

on

product

risk

NOTE: A

processor

cannot offer

foods for sale

until they

have received

their license

Warning

Food found in the

market from an

‘unapproved’ is

subject to seizure

Good Manufacturing

Practices (GMPs)

GMP Category

GMP Requirement For:

Personnel

1. Disease control

2. Cleanliness

3. Education and training

4. Supervision of personnel with regards to these requirements

Building

and Grounds

1. Description of adequate maintenance of grounds/exterior of

facility

2. Facility/kitchen construction and design to facilitate sanitary

operations and maintenance

Sanitary Operations

1. Cleaning/sanitizing of physical facilities, utensils, and

equipment

2. Storage of cleaning and sanitizing substances

3. Pest control

4. Sanitation of food contact surfaces

5. Storage and handling of cleaned portable equipment and

utensils

Sanitary Facilities and

Controls

1. Water supply

2. Plumbing

3. Sewage disposal

4. Toilet facilities

5. Hand

-washing facilities

6. Rubbish and offal disposal

Equipment and Utensils

Design, construction, and maintenance of equipment and utensils

Processes and controls

Delineates processes and controls for:

1. Raw materials and other ingredients (separation, storage,

rotation,

etc)

2. Manufacturing operations (critical limits, allergen control,

cross contamination,

etc)

Warehousing

/ Storage

and distribution

Storage and transportation of final food product must protect

against contamination and deterioration of the food and its

container

Good manufacturing practices provide guidance

for manufacturing, testing, and quality assurance

of food to ensure that a food product is safe for

human consumption.

All GMP guidelines follow a few basic principles:

1. Instructions and procedures must be written

in clear and unambiguous language

2. Records produced during the

manufacturing/food process (temperature

controls, cleaning/sanitation schedules,

training, batch, lot codes, etc) must be

maintained

Provided in your

handout

GMP - Personnel

The facility management shall take all reasonable measures and precautions to assure the

following:

Disease control. No person affected by disease in a communicable form, or while a carrier

of such disease, or while affected with boils, sores, infected wounds, or other abnormal

sources of microbiological contamination, shall work in a food plant in any capacity in

which there is a reasonable possibility of food or food ingredients becoming contaminated

by such person, or of disease being transmitted by such person to other individuals.

Devise a policy

Share the policy with employees

GMP - Personnel

Cleanliness. all persons, while working in direct contact with food preparation, food

ingredients, or surfaces coming into contact therewith shall:

Wear clean outer garments, maintain a high degree of personal cleanliness, and conform to

hygienic practices while on duty, to the extent necessary to prevent contamination of food

products.

Wash their hands thoroughly (and sanitize if necessary to prevent contamination by undesirable

microorganism) in an adequate hand-washing facility before starting work, after each absence

from the work station, and at any other time when the hands may have become soiled or

contaminated.

Remove all insecure jewelry and, during periods where food is manipulated by hand, remove

from hands any jewelry that cannot be adequately sanitized.

If gloves are used in food handling, maintain them in an intact, clean, and sanitary condition.

Such gloves should be of an impermeable material except where their usage would be

inappropriate or incompatible with the work involved.

Wear hair nets, headbands, caps, or other effective hair restraints.

Not store clothing or other personal belongings, eat food or drink beverages, or use tobacco in

any form in areas where food or food ingredients are exposed or in areas used for washing

equipment or utensils.

Take any necessary precautions to prevent contamination of foods with microorganisms or

foreign substances including, but not limited to, perspiration, hair, cosmetics, tobacco,

chemicals and medications.

Personnel - The Good, the Bad and the Ugly

The Good The Bad The Ugly

Buildings and Grounds The Good, the Bad and the Ugly

The Good The Bad The Ugly

GMP – Sanitary Operations

You must have program in place to ‘maintain a clean and

sanitary operation’.

When possible a program must be available and documented

for the following:

➢ General maintenance of buildings and grounds

➢ Animal and vermin control

➢ Sanitation of equipment and utensils

➢ Sanitation/cleaning of walls, floors, ceilings etc

Sanitary Operations - The Good, the Bad and the Ugly

The Good The Bad The Ugly

GMP – Sanitary Facilities & Controls

Each facility shall be equipped with adequate sanitary facilities and

accommodations, including but not limited to the following:

Water supply

Sewage disposal

Plumbing

Toilet facilities

Hand-washing facilities

Rubbish and offal disposal

Sanitary Facilities & Controls The Good, he Bad and the Ugly

The Good The Bad The Ugly

GMP – Equipment & Utensils

All plant equipment and utensils should be:

suitable for their intended use,

so designed and of such material and

workmanship as to be adequately cleanable,

and

properly maintained.

Equipment The Good, the Bad and the Ugly

The Good The Bad The Ugly

GMP – Processes and Controls

Raw material and ingredients shall be segregated as necessary to

assure that they are clean, wholesome, and fit for processing

into human food

Raw materials shall be stored under conditions that will protect

against contamination and minimize deterioration.

Containers and carriers of raw ingredients should be inspected

on receipt and routinely to assure that their condition has not

contributed to the contamination or deterioration of the

products

GMP – Processes and Controls

When ice is used in contact with food products, it shall be made

from potable water

Food-processing areas and equipment used for processing human

food should not be used to process non-human food-grade

animal feed or inedible products unless there is no reasonable

possibility for the contamination of the human food.

Processing equipment shall be maintained in a sanitary condition

through frequent cleaning including sanitization where

indicated.

Insofar as necessary, equipment shall be taken apart for

thorough cleaning.

Processes and Controls - The Good, the Bad and the Ugly

The Good The Bad The Ugly

GMP – Warehouse, Storage and Distribution

All food packaging and storage, should be conducted under such conditions

and controls as are necessary to minimize the potential for undesirable

deterioration or contamination of the processed product or ingredients

Storage may require careful monitoring of such physical factors as:

Time,

Temperature,

Humidity,

Pressure,

Flow-rate

Processing operations as freezing, dehydration, heat processing, and refrigeration

Testing procedures shall be utilized where necessary to identify sanitation

failures or food contamination

Packaging processes and materials shall not transmit contaminants or

objectionable substances to the products

GMP – Warehouse, Storage and Distribution

Meaningful coding of products sold or otherwise distributed from

a manufacturing, processing, packing, or repacking activity

should be utilized to enable positive lot identification to

facilitate

Records should be retained for a period of time that exceeds the

shelf life of the product

Storage and transportation of finished products should be under

such conditions as will prevent contamination and will protect

against undesirable deterioration of the product and the

container

Warehouse, Storage and Distribution -The Good, the Bad and the Ugly

The Good The Bad The Ugly

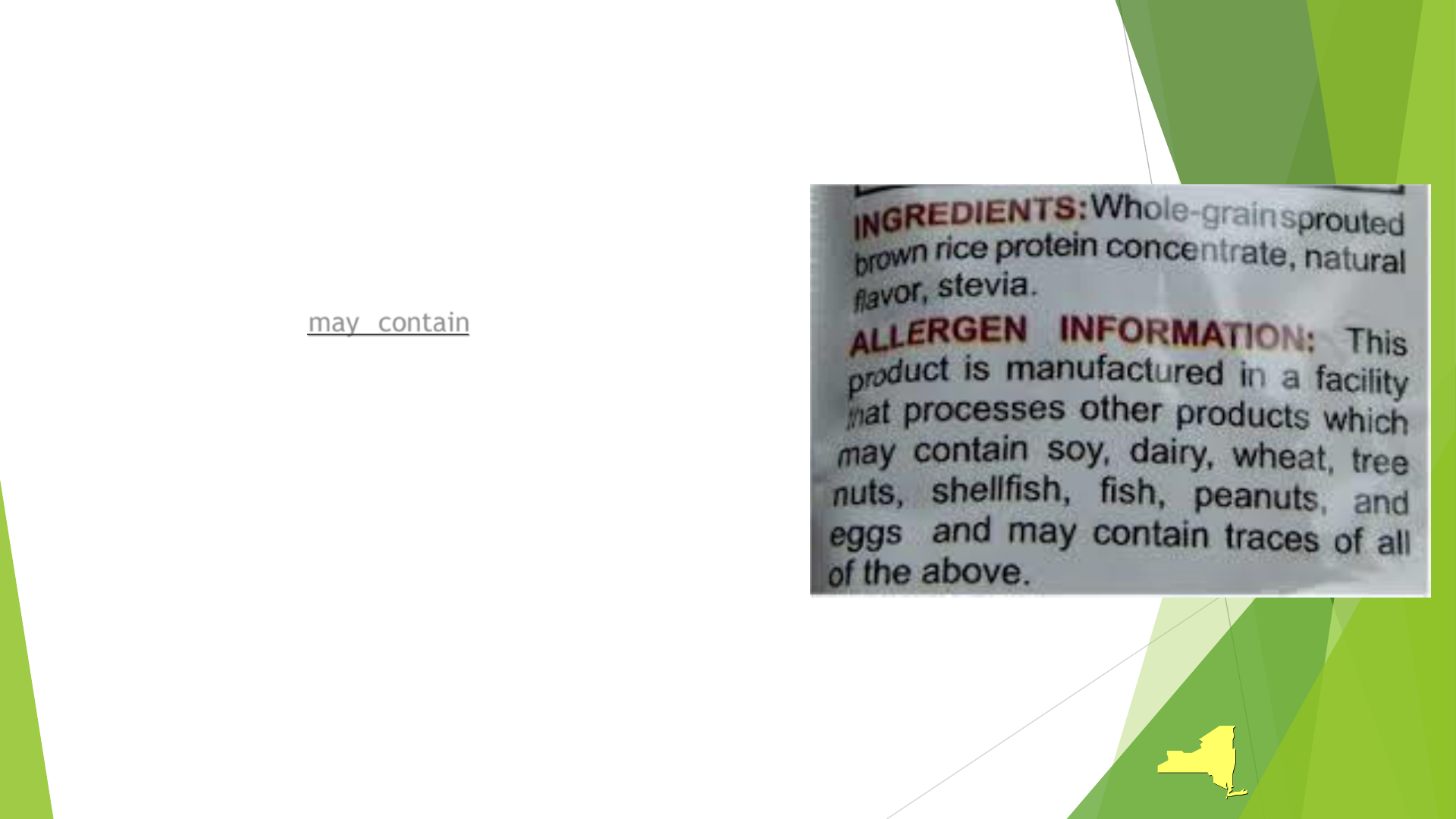

Allergens

Food labels must identify the source of all major allergens in the food’s ingredient list

in simple language.

Unless the food source of a major food allergen is part of the ingredient’s common and

usual name (e.g. milk, wheat), it must be labeled in one of two ways. It may be added

in parenthesis after the ingredient (e.g. whey (milk), flour (wheat)) or can be

identified at the end of the ingredient list in a “contains” statement (e.g. contains

milk and wheat).

What are the major food allergens in the US? Worldwide?

Milk,

Eggs,

Fish,

Crustacean shellfish (e.g. shrimp, crab, lobster),

Tree nuts (e.g. almonds, walnuts, pecans, etc.),

Peanuts,

Wheat,

Soybeans.

Allergens - The Good, the Bad and the Ugly

The BadThe Good The Ugly

Cross Contact/Contamination

What is cross-contact/contamination?

Cross-contact occurs when a residue or trace amount of an

allergen unintentionally crosses over into a product that

doesn’t have that allergen.

Cross-contact (the inadvertent introduction of an allergen into

a product) is generally the result of environmental exposure

during food processing or handling.

Cross-contact occurs when:

multiple foods are manufactured on the same processing line,

through the misuse of rework,

as a result of ineffective cleaning, or

from the generation of significant dust containing the allergen.

Cross Contact/Contamination

How can cross-contact be prevented?

Cross-contact cannot always be prevented. However, by developing and implementing an

Allergen Control Plan, one can either prevent or at least minimize allergen cross-contact

as much as possible.

The Allergen Control Plan is a written document outlining controls put in place

regarding the:

storage, handling, and processing of allergens and

the identification of places where cross-contact is likely to occur.

NOTE: Prevention and monitoring methods are included to prevent cross-contact.

An effective Allergen Control Plan should start with the production of raw materials,

storage and handling of raw materials, and every step in the manufacturing process

through the packaging and labeling of the finished product.

The critical points where allergens may be introduced into the product during

manufacturing should be identified and a system established to monitor these points

to ensure unintentional cross contact is prevented.

Cross Contact/Contamination

What is precautionary allergen labeling?

Precautionary allergen labeling (sometimes also referred

to as allergen advisory labeling) is a voluntary warning to

consumers (e.g. may contain milk) added after the

ingredient list.

It’s goal is to indicate a product not intended to contain

a specific allergen(s) may sporadically contain that

allergen due to unintentional and unavoidable cross-

contact in the manufacturing process even after

implementing a comprehensive Allergen Control Plan.

Traceability - Recall Plan

Traceability

Ability to track food through

the food system back to their

source and forward to the next

destination

DOES NOT prevent a foodborne

outbreak

CAN quickly identify the source

of a product and speed an

investigation

CAN limit damage to the

consumer

CAN prevent damage to the

innocent ‘processor’

Product Recall

Recalls are actions taken by a

firm to remove a product from

the market.

They may be conducted

on your own initiative,

By request of your buyer,

by NYSDAM/FDA request, or

by FDA order under court

order.

Recall Plan Development

How to make your products traceable

Keep records of

name of the product,

the ingredients & manufacturers,

the processing area,

processing dates (or group of dates),

LOT numbers, and

where it was sent.

Use processing records, receipts, transportation bills, and

storage records to provide documentation.

Keep records for products that are held in storage before

distribution

NOTE: ALWAYS

CHECK THAT IT

WORKS

Preparing for your ‘Inspection’ through a

‘Self-Audit’

Personnel

Grounds/

Building

Sanitation

Equipment

Storage/

Transportation

Food Labeling

1. Where should label statements be placed on containers and packages?

Answer: There are two ways to label packages and containers:

a. Place all required label statements on the front label panel (the

principal display panel or PDP), or,

b. Place certain specified label statements on the PDP and other labeling

on the information panel (the label panel immediately to the right of the

PDP, as seen by the consumer facing the product).

21 CFR 101.1, 21 CFR 101.2, 21 CFR 101.3, 21_

CFR 101.4, 21 CFR 101.5, 21 CFR 101.9, and 21 CFR 101.105

2. What are the PDP and the alternate PDP?

Answer: The PDP, is that portion of the package label that is most likely to be

seen by the consumer at the time of purchase. Many containers are designed

with two or more different surfaces that are suitable for display as the PDP.

These are alternate PDPs. 21 CFR 101.1

3. What label statements must appear on the PDP?

Answer: Place the statement of identity, or name of the food, and the net

quantity statement, or amount of product, on the PDP and on the alternate

PDP. The required type size and prominence are discussed

in sections 4and 5 of this guidance. 21 CFR 101.3(a) and 21 CFR 101.105(a).

4. Which label panel is the information panel?

Answer: The information panel is the label panel immediately to the right of

the PDP, as displayed to the consumer. If this panel is not usable, due to

package design and construction, (e.g., folded flaps), then the information

panel is the next label panel immediately to the right. 21 CFR 101.2(a)

5. What is information panel labeling?

Answer: The phrase "information panel labeling" refers to the label

statements that are generally required to be placed together, without any

intervening material, on the information panel, if such labeling does not appear

on the PDP. These label statements include the name and address of the

manufacturer, packer or distributor, the ingredient list, nutrition labeling and

any required allergy labeling. 21 CFR 101.2(b) and (d), Section 403(w) of the

FD&C Act

6. What type size, prominence and conspicuousness is required?

Answer: For information panel labeling, use a print or type size that is prominent, conspicuous and

easy to read. Use letters that are at least one-sixteenth (1/16) inch in height based on the lower case

letter "o". The letters must not be more than three times as high as they are wide, and the lettering

must contrast sufficiently with the background so as to be easy to read. Do not crowd required

labeling with artwork or non-required labeling.

Smaller type sizes may be used for information panel labeling on very small food packages as

discussed in 21 CFR 101.2(c) & (f).

Different type sizes are specified for the Nutrition Facts label. (see section 7)

The type size requirements for the statement of identity and the net quantity statement are discussed

in sections 4 and 5 of this guidance. 21 CFR 101.2(c)

7. What is the prohibition against intervening material?

Answer: Information that is not required by FDA is considered intervening material and is not

permitted to be placed between the required labeling on the information panel (e.g., the UPC bar

code is not FDA required labeling). 21 CFR 101.2(e)

8. What name and address must be listed on the label?

Answer: Food labels must list:

a. Name and address of the manufacturer, packer or distributor. Unless the name given is the

actual manufacturer, it must be accompanied by a qualifying phrase which states the firm's

relation to the product (e.g., "manufactured for "or "distributed by");

b. Street address if the firm name and address are not listed in a current city directory or

telephone book;

c. City or town;

d. State (or country, if outside the United States); and

e. ZIP code (or mailing code used in countries other than the United States). 21 CFR 101.5

Food Labeling – Continued

HAZELS

Blueberry Muffin Mix

Artificially flavored

NET WT. 12 oz. (340g)

HAZELS

Wild Blueberry

Mix

Naturally flavored

SO GOOD

NET WT. 12oz

.

Enriched Bleached flour (niacin, iron, riboflavin),

sugar, artificial blueberry bites (palm oil, corn

flour, artificial flavor, red coloring), vegetable oil,

baking soda, corn starch, salt, eggs, sodium

silicoaluminate.

May contain: milk and soy

Serving Size: 1/6 pouch (31g), Servings per Container: 6

Amount Per Serving, Calories 120,Calories from Fat 25, %

Daily Value, Total Fat 2.5g (4%) , Saturated Fat 1g (4%),

Trans Fat, 1g,Cholesterol 0mg (0%),Sodium 230mg

(10%),Total Carb 23g (8%)

Sugars 11g, Protein 1g, Iron 2%, Thiamin 4%

Riboflavin 2%, Niacin 2%,

Not a significant source of dietary fiber, vitamin A and vitamin

C and calcium.

* Percent Daily Values are based on a 2,000 calorie diet.

Distributed by Lazurne’s LLC

Hamilton, NY

Hazelsfoods.com

Enriched Bleached flour (wheat flour, niacin,

iron, riboflavin), sugar, artificial blueberry

bites (palm oil, corn flour, artificial flavor, red

40, blue 1), vegetable oil (sunflower, and

peanut oil), baking soda, corn starch, salt,

eggs, sodium silicoaluminate (anticaking

agent).

Distributed by Lazurne’s LLC

64 Lake Rd.

Hamilton, NY 12202

A SPOT THE DIFFERENCE B

Take a look at the label and circle what you

think is wrong with the picture!

Food Safety Training

As required by Agriculture and Markets Law §251-z-312, the applicant for a food processing

establishment license shall furnish evidence of his or her experience and competency to

operate the establishment. One can demonstrate such competency by successfully

completing a food safety course approved by the Department.

The food safety course shall consist of not less than eight hours of training received

within two years prior to the commencement of the license period or, if the program

required the passing of a test, within five years prior to the commencement of the

license period.

The program shall cover one or more of the following topics:

New York State food safety statutes and regulations;

Food microbiology, including a review of pathogenic and spoilage microorganisms;

food-borne illnesses, including causative agents, symptoms, and prevention;

HACCP (Hazardous Analysis Critical Control Point);

Cleaning and sanitation;

Personal hygiene;

Temperature control, including heating, cooling, and storage standards; and

Food security, including identifying risks, implementing preventive measures and pest

control.

‘Scheduled’ Process Review

1 NYCRR 271.9.3:

A scheduled process or process review must be conducted on food products that

ordinarily do not have a processing step that addresses the rationale for how the

potential public health hazards and insanitary conditions addressed by the

relevant regulatory sections will be alternatively addressed by the new process.

The schedule process or process review must outline at a minimum recipe

testing/formulation, critical control points (to avoid contamination and control

hazards), processing steps, storage requirements, distribution and selling

conditions/restrictions, etc.

A scheduled process or process review of your new product can be obtained by

contacting any of the parties listed under the ‘Process Review

1

’ section on the

website

1

Listing of ‘Recognized Processing Authority’ is available for download from our website

‘Scheduled’ Process Review

The department requirements for producing a for wholesale distribution are as

follows:

Completion of a scheduled hazard/process review conducted by a recognized process

authority

1

.

Completion of Article 20-C Food processing establishment license application.

Compliance with 1NYCRR Part 261 – Current good manufacturing practices.

Compliance with 1NYCRR Part 59.1 – Packaging and labeling of food (including

statement of identify, net quantity statements, ingredients, warnings, refrigeration

statements etc) See labeling slides

The department requirements for producing a product for retail sale are as follows:

Adherence to a variance as required under 1NYCRR Part 271.9 – Retail food store

sanitation regulations, compliance and enforcement.

Completion of Article 20-C Food Processing Establishment license application.

Compliance with 1NYCRR Part 271 - Retail food store sanitation regulations.

Compliance with 1NYCRR Part 59.1 – Packaging and labeling of food (including warning

refrigeration statements etc).

1

Listing of ‘Recognized Processing Authority’ is available for download from our website

Helpful Resources for Small Scale Food

Processors

Request the publication: Small Scale Food Entrepreneurship: A Technical

Guide for Food Ventures from Elizabeth Keller, 315-787-2273

or [email protected] or access the online

version: http://www4.gsb.columbia.edu/filemgr?file_id=738927

Product development, processing and distribution assistance is also available

from Nelson Farms at SUNY Morrisville – 315-655-8831

or www.nelsonfarms.org

To learn about small scale food processing activities in NYS, join the NYS

Small Scale Food Processors Association: www.nyssfpa.com and become a

member of Pride of NY – 800-554-4501

NYSDAM – Excellent Food Safety Resources

Review the following Circulars on the NYSDAM

website:

Circular 951 - Pursuant to the Licensing of

Food Processing Establishments

Circular 938 – Rules and Regulations Relating

to Food Processing Establishments

Circular 933 - Good Manufacturing Practices

BE READY FOR YOUR NEXT NYSDAM INSPECTION BY CHECKING

OUT OUR INSPECTION CHECKLIST/CATEGORIES

Regional Offices of the NYS Department of

Agriculture and Markets

Division of Food Safety and Inspection

55 Hanson Place,

Brooklyn, NY 11217-1583

Phone: 718-722-2876

Division of Food Safety and Inspection

Electric Tower Building, 535 Washington

Street, 2nd Floor Suite 203,

Buffalo, NY 14203

Phone: 716-847-3185

Division of Food Safety and Inspection

900 Jefferson Road, Rochester, NY 14623

Phone: 585-487-0200

Division of Food Safety and Inspection

NYS Fairgrounds – Art and Home Center, Syracuse, NY 13209

315-487-0852

US FDA

300 Pearl Street, Suite 100, Buffalo, NY 14202

716-551-4478

US FDA New York District Office

158-15 Liberty Avenue, Jamaica, NY 11433

718-662-5447

United States Department of Agriculture – Food Safety

Inspection Service (USDA FSIS)

5 Washington Square, Albany, NY 12205

518-457-4492

Focus on Prevention

FDA Food Safety

Modernization Act (FSMA)

Why is the law needed?

Foodborne illness is a significant burden

About 48 million (1 in 6 Americans) get sick each year

128,000 are hospitalized

3,000 die

Food supply more high-tech and complex

15 percent of U.S. food supply is imported

More foods in the marketplace

New hazards in foods not previously seen

Main Themes of the Legislation

Prevention

Inspections,

Compliance,

and Response

Import Safety

Enhanced

Partnerships

General Approach to FSMA

5. Review

& Adjust

2. Understand

Cause

3. Implement

Preventive

Controls

4. Monitor

Effectiveness

FSMA Preventive Controls

Comprehensive preventive controls

for human and animal food

facilities

Prevention is not new, but Congress

has given FDA explicit authority to

use the tool more broadly

Produce safety standards

Supplier verification standards

Import standards

Transportation standards

1. Identify Hazard

HACCP

HACCP (Hazard Analysis & Critical Control Points) Plans are mandated by FDA

regulations for certain products and processes, specifying procedures to be followed

to minimize contamination and to minimize/eliminate chemical, physical and

biological hazards when processing foods.

HACCP plans are required for wholesale sale (not for retail) of:

Seafood,

Dairy,

Meat and poultry products,

Juice and cider processing facilities

Registration with FDA? Processors and food facilities are required

to register with the FDA according to the Bioterrorism Act of 2002.

Registration information may be found at:

https://www.fda.gov/Food/GuidanceRegulation/FoodFacilityRegist

ration/default.htm

HACCP -vs- FSPC

16

HACCP

Built on a foundation of GMP’s

and prerequisite programs

Focuses on specific Process

Control Steps

Hazard Analysis

HACCP Plan – All CCP’s have critical

limits.

Monitoring, Corrective

Actions, Verification, Record

Keeping

What you will do

Food Safety Preventive

Controls

(aka FSMA)

Built on a foundation of GMP’s

and prerequisite programs

HACCP on Steroids - Includes other

elements in addition to process control steps

Hazard Analysis – Includes radiological

hazards

Food Safety Plan – not all preventive

controls have critical limits.

Monitoring, Corrective Actions,

Verification, Record Keeping

How you will do it

Components of Preventive Controls for

Human Foods Rule

17

Key Requirements:

Establish a Food Safety System that includes an analysis of

hazards and risk based preventive controls leading to the

creation of the Food Safety Plan…

▪ Hazard Analysis

▪ Preventive Controls

▪ Oversight

- Monitoring

- Corrective Action & Corrections

- Verification

Contents of a Food Safety Plan

Process

Control

Sanitation

Control

Allergen

Control

Supply

Chain

Program

Hazard

Analysis

Recall

Plan

Food Safety Plan

Including procedures for monitoring,

corrective action and verification

GMP’s and Other

Prerequisite Programs

Modified Requirements for Qualified Facilities

(Section 103)

Facility is exempt if:

Defined as very small business;

OR

The facility has a limited annual monetary value of

sales

Limited annual monetary value of sales is defined as:

During the last 3 years, sales were less than

$500,000;

AND

Sales to "Qualified End Users" exceed sales to others

Examples of Compliance with

Prevention Standards

Current Good Manufacturing Practices (cGMPs)

Sanitation

Training for supervisors and employees

Hazard Analysis and Risk-Based Preventative

Controls

Food Safety Plan

Hazard analysis

Preventive controls (chemical, physical,

biological)

Control monitoring, verification, validation

Recall contingency plan

Supplier verification activities

Will FSMA

apply to

YOU?

Check out

our website

for further

details

Transportation of Food

Sec. 111. Sanitary Transportation of Food

Addresses implementation of the Sanitary Food Transportation Act of 2005, which requires

persons engaged in food transportation to use sanitary transportation practices to ensure

that food is not transported under conditions that may render it adulterated.

Specific exemptions to this include:

Transportation of Grade “A” milk and milk products

Food establishments authorized by the regulatory authority to operate when engaged as

receivers, or as shippers and carriers in operations in which food is delivered directly to

consumers, or to other locations the establishments or affiliates operate that serve or sell

food directly to consumers. (Examples include restaurants, supermarkets and home grocery

delivery services.)

Businesses transporting molluscan shellfish (such as oysters, clams, mussels or scallops) that

are certified and inspected under the requirements established by the Interstate Shellfish

Sanitation Conference’s (ISSC) National Shellfish Sanitation Program (NSSP) and that

transport the shellfish in vehicles permitted under ISSC authority.

Import Prevention Program

Sec. 301 Foreign Supplier Verification Program (FSVP)

Requires importers to conduct risk-based foreign supplier verification activities

to verify that food imported into the United States is not adulterated and that

it was produced in compliance with FDA’s preventive controls requirements

and produce safety standards

Sec. 307. Third Party Auditor Accreditation

Can be used by importers for supplier verification under FSVP

The following third party certifying bodies specialize in food safety inspection

and sanitation (please be advised, however, that NYSDAM makes no

representation as to the competency of any particular certifying body nor

should or will it be held liable for any action taken by a certifying body:

http://www.sqfi.com/

http://www.mygfsi.com/

http://www.brcglobalstandards.com/

http://www.primuslabs.com/services/AuditorTypes.aspx

FDA and NYSDAM FSMA Implementation Approach

NYSDAM Implementation (multiple year

approach)

Conduct outreach to determine Industry

size, exemptions, applicability

Develop a dataset of ‘affected’ facilities

Classify facilities : Facilities will be ranked

according to their risk classification and

prioritized based on public health

protection

Educate those affected

Engage stakeholders to help determine

reasonable and practical ways to implement

preventive control provisions

Work with stakeholders to implement

provisions

Visit and work with affected facilities (large,

small, very small) to identify gaps with

compliance and educate accordingly

Begin inspection protocol

Begin enforcement protocol

FDA Implementation

Items are prioritized based on public

health protection

Engage with stakeholders to help

determine reasonable and practical ways

to implement preventive control provisions

Implementation progress at

http://www.fda.gov/fsma

Registration with the FDA will

be key!

NOTE: FDA registration does

not substitute the need to

notify NYSDAM of your

business or completion of

license application

Questions?

Don’t forget to pick

up all your resource

guides/handouts!!