HITACHI Printer

Instruction Manual

INK JET PRINTER FOR INDUSTRIAL MARKING

Model RX2

Thank you for purchasing the Hitachi IJ Printer Model RX2.

This printer employs a noncontact, ink-jet method to print onto a print target.

This instruction manual describes the basic operating procedures, maintenance procedures, and other detailed

handling procedures of the Hitachi IJ Printer Model RX2.

If the printer is improperly handled or maintained, it may not operate smoothly and may become defective or

cause an accident. It is therefore essential that you read this manual to gain a complete understanding of the

printer and use it correctly.

After thoroughly reading the manual, properly store it for future reference.

IF you changed the language of the screen by mistake, see Chapter 7.8 "Selecting Languages".

●Safety Precautions (1)

SAFETY PRECAUTIONS

● Before using the printer, thoroughly read the following safety precautions for optimum printer

use.

● You should observe the precautions set forth below in order to use the product properly and

avoid endangering you or other persons or damaging property. For the purpose of clarifying

the severity of injury or damage and likelihood of occurrence, the precautions are classified

into two categories, WARNING and CAUTION, which both describe hazardous situations

that may arise if you ignore the precautions and perform an incorrect handling or operating

procedure. The precautions in these two categories are both important and must therefore

be observed without fail.

WARNING

WARNING is used to indicate the presence of a hazard which

may cause severe personal injury or death if the warning against

performing an incorrect handling procedure is ignored.

CAUTION

CAUTION is used to indicate the presence of a hazard which

may cause personal injury or property damage if the warning

against performing an incorrect handling procedure is ignored.

● If the warning in the CAUTION category is ignored, serious results may occur depending on

the situation.

● After the manual has been read, it must be stored in such a location that all printer operation

personnel can refer to it at all times.

● All the instructions set forth in this manual are important and must therefore be observed

without fail.

Pictograph Examples

The symbols are used to indicate precautions (including those related to

potential warnings) to be observed. Detailed information is furnished by a picture

within the symbol outline (a shock hazard is indicated by the example shown at

left).

The symbols are used to describe prohibited actions. The details of a

prohibited action are given by a picture within or near the symbol outline (the

example shown at left dictates that you must keep flames away).

The symbols are used to describe required actions. Detailed instructions are

given by a picture within the symbol outline (the example shown at left dictates

that a ground connection must be made).

User hereby agrees not to export or re-export this product to any end-user who the user

has reason to suspect may utilize the product for the design, development or reproduction

of nuclear, chemical or biochemical weapons.

Restrictions on Export

File management and USB management are carried out using eParts made from eSOL.

Ethernet is the product name of Xerox Corporation in America.

(2) ●Safety Precautions

SAFETY PRECAUTIONS (Continued)

WARNING

● Ensure that there is no flame- or arc-generating device around the

printer.

The ink and makeup are both flammable and may cause fire.

Fire can be generated by matches, lighters, cigarettes, heaters, stoves, gas

burners, welders, grinders and static electricity. Arcs may be generated from

open-type relays, switches, and brush motors. Before handling the ink and

makeup, remove static electricity from your body, peripheral equipment, and so

on. In the interest of safety, position a dry-chemical fire extinguisher near the

printer.

● Since the ink and makeup contain organic solvents, install the printer at

an adequately ventilated location.

Never install the printer in an enclosed space.

Connect exhaust equipment to the printer in order to prevent it from filling

with organic solvent vapor.

● Do not insert tweezers, a screwdriver, or any other metal article into the

ink ejection hole in the end of the print head.

When the printer is ready to print, a high voltage (approximately 6 kV) is applied

to the deflection electrode section in the print head.

Exercise caution to avoid electric shock, injury, and fire.

● Do not remove the outer covering.

A high voltage is applied to some sections of the printer.

Exercise caution to avoid electric shock and injury.

● Use an AC voltage of 100 to120 V or 200 to 240 V ±10% only and a

power frequency of 50 or 60 Hz only.

If the above requirements are not met, the electric parts may overheat and burn,

creating a risk of fire or electric shock.

● Never drain the ink or makeup waste solution into a public sewer system.

Waste disposal must comply with all appropriate regulations. Consult the

appropriate regulatory agency for further information.

● Exercise caution to avoid inadvertently disconnecting, forcibly pulling, or

bending piping tubes.

Since the ink and makeup in some portions of piping tubes are pressurized,

they may splash into your eyes or mouth or onto your hands or clothing.

If any ink or makeup enters your eyes or mouth, immediately flush with warm or

cold water and consult a physician.

1

2

●Safety Precautions (3)

SAFETY PRECAUTIONS (Continued)

WARNING

● While the printer is operating, do not look into the ink ejection hole in the

end of the print head.

Ink or makeup may enter your eyes or mouth or soil your hands or clothing.

If any ink or makeup enters your eyes or mouth, immediately flush with warm or

cold water and consult a physician.

● Before servicing the printer, be sure to stop the ink ejection.

Because ink or makeup may splash into your eyes or mouth or onto your hands

or clothing. If any ink or makeup enters your eyes or mouth, immediately flush

with warm or cold water and consult a physician.

● If an earthquake, fire, or other emergency occurs while the printer is

engaged in printing or just turned on, press the Main power switch to turn

off the power.

● The printer must be managed in compliance with all appropriate

regulations.

Read and understand the appropriate Safety Data Sheet (SDS) before using

any ink or makeup.

● Use Hitachi approved consumables and periodic replacement parts.

Using products that are not designated by Hitachi could cause s failure in

certain functions.

● Warning for Mercury

-- THE LAMP IN THIS PRODUCT CONTAINS MERCURY.

RECYCLE OR DISPOSE OF IT ACCORDING TO APPLICABLE

ENVIRONMENTAL LAWS.

For Recycling and Disposal information, contact your government agency, the

Electronic Industries Alliance at www.eiae.org, and/or www.lamprecycle.org (in

the US), or the Electronic Product Stewardship Canada at www.epsc.ca (in

Canada). For more information, call 1-800-HITACHI (1-800-448-2244) (in the

US).

Hg

(4) ●Safety Precautions

SAFETY PRECAUTIONS (Continued)

WARNING

● When charging a refill of ink or makeup, exchanging ink, or otherwise

handling ink or makeup, take enough care not to spill ink or makeup.

If you spill any ink or makeup by mistake, wipe it off neatly and promptly with

wiping paper or something similar. Do not close the maintenance cover until

you make sure that the portion you have just wiped is completely dry.

You must pay particular attention when you have spilled ink or makeup inside

the printer and it is not completely dry. Why? Because vapors of ink or

makeup will stay inside the printer and may catch on or cause a fire.

If you find it hard to wipe the printer when it is turned on, stop it with the maintenance

cover open. Power it down, and then wipe it off again.

● If you wish to clean the casing of the printer with wiping paper impregnated

with makeup, be sure to do so with the power off.

Attempting to clean it when the power is on will cause makeup or vapors of makeup

to enter the printer, possibly catching on or causing a fire.

When the cleaning is over, open the maintenance cover and make sure that no

makeup has entered and no vapors remain inside.

● Should you find a leak of ink or makeup inside the printer while the printer is

running or being maintained, wipe it off promptly with wiping paper or

something similar. Then, with the maintenance cover open, stop the printer,

power it down, and repair the leak.

Continuing operation with a leak of ink or makeup will cause an anomaly,

resulting in abnormal printing.

Ink and makeup are flammable. They may therefore catch on or cause a fire.

● The ink and makeup, their waste solution, used wiping papers and empty

containers are flammable. Waste disposal must comply with appropriate

regulations. Consult the appropriate regulatory agency for further information.

● If you wish to receive ink particles in a beaker, for a printing test for example,

use an electrically conductive beaker and connect the beaker securely to the

ground.

Do not let the tip of the printing head enter the beaker.

Ink particles used for printing are electrically charged. An ungrounded beaker has a

gradually rising charge, possibly catching on or causing a fire.

● Ensure that all electrical wiring, connections and grounding comply with

applicable cords. Properly connect the printer to its dedicated ground.

Complete the above procedure to avoid electrical shock hazards.

● When welding, keep enough space between the IJ printer and the welding

work area to prevent the arc from starting a fire. Also, be sure to insulate the

printhead and IJ printer frame to keep the welding current from flowing to the

control section of the printer, and to make a separate ground connection for

the printer.

●Safety Precautions (5)

WARNING

<Keep all fire away.>

○ Ink and Makeup are flammable.

○ All fire must be kept away from the machine.

○ Spilled Ink and Makeup must be wiped off and dried up immediately.

<Caution when handling Ink/Makeup>

○ Strage must comply with local regulatory requirements .

○ Read and understand Safety Data Sheet(SDS).

○ Be sure to wear protective gloves and safety goggies.

○ If the Ink/Makeup in used is an organic solvent,it must be managed in compliance with the

Ordinance on the prevention or Organic Solvent poisoning.Refer to the "Instruction Manual"and

the "Handling guidance of each ink" for details.

AVERTISSEMENT

< Tenir hors de portée du feu. >

○ L’encre et la composition sont inflammables.

○ Tenir la machine hors de portée du feu.

○ Nettoyez et séchez immédiatement les projections d’encre et de composition.

<Soyez prudent lorsque vous manipulez l’encre/la composition>

○ Le stockage doit respecter les obligations réglementaires locales.

○ Lisez attentivement la fiche signalétique de sécurité de l’appareil (FSSP).

○ Assurez-vous de porter des gants et des lunettes de protection.

○ Si l’encre/la composition utilisée est un solvant biologique, vous devez le manipuler

conformément au décret sur la prévention des empoisonnements par solvant biologique.

Reportez-vous au «Mode d’emploi» et aux «Conseils de manipulation de chaque type d’encre»

pour plus de détails.

SAFETY PRECAUTIONS (Continued)

(6) ●Safety Precautions

SAFETY PRECAUTIONS (Continued)

CAUTION

● Only persons who have completed an operator training course for

Hitachi IJP can operate and service the printer.

If the printer is operated or serviced incorrectly, it may malfunction or break

down.

● Do not attempt to make repairs for any purpose other than operation or

maintenance.

● Since the ink and makeup contain organic solvents, observe the

following handling precautions.

Secure adequate space for the ink/makeup handling area and printer

installation site. At least 200 m must be provided per print head.

Ensure that adequate ventilation is provided.

When handling the ink or makeup, wear protective gloves and safety goggles

to avoid direct skin contact. If the ink or makeup comes into contact with

skin, wash thoroughly with soap and warm or cold water.

When transferring the ink or makeup to or from a bottle, exercise caution to

prevent it coming into contact with the printer or surrounding articles.

If there is any spillage, immediately wipe it clean using a cloth moistened

with makeup.

● Ink and makeup must be stored as flammable liquids. Storage must

comply with local regulatory requirements. Consult the appropriate

regulatory agency for further information.

● If extraneous noise enters the printer, it may malfunction or break down.

For maximum noise immunity, observe the following installation and wiring

precautions.

Ensure that 100 to 120 VAC or 200 to 240 VAC power cables are not

bundled with other power supply cables.

Insulate the printer main body and print head so that they do not come into

direct contact with the conveyor or other devices.

If the employed print target detector is housed in a metal case, use a plastic

mounting brace for the purpose of insulating the detector from the conveyor

and other devices.

Be sure that the print target detector wiring is not bundled together with other

power supply cables.

● Please make sure the print status and print content are correct each time when

you start operation of IJP.

● Please implement periodical checkup of print status in the process, even

including during production.

● A touch panel is employed for data entry to operation screen.

When manipulating the Touch panel, use only fingers. If the touch panel is

operated with metal and/or sharp objects such as ball point pen, it may

malfunction or break down.

1

2

3

3

2

1

3

4

●Safety Precautions (7)

SAFETY PRECAUTIONS (Continued)

FCC Notice

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

(8) ●Security Precautions

SECURITY PRECAUTIONS

CAUTION

In the control system, the connection with the information and telecommunications system is

progressing recently, and it causes for the increased security risk such as cyber attacks.

In a system applying this product, both physical security measures mainly in the installation location

and security measures against the network usage are required.

[Security risk example via the network]

● Abnormal operation, performance degradation, information leakage and data tampering by

attacks from outside

● Malfunction, harm and damage occurrence due to programs and/or data tampering from

outside

● It is used as an attacking step for other systems

However, the security level to be determined varies by each control system. In addition, the

assumed security risk is not fixed, it will be something to change on a daily basis.

Not only in our products, individual security protection support functions of each product configuring

the system is one means to ensure the security level required for the system, it does not completely

prevent the security risk growing day by day.

The construction of the security level required for the control systems are responsible by the system

and customer. In addition, for the maintenance of the security level will require continuous

improvement of measures.

In a system using this product, trouble, accident or damages caused by unauthorized external

access, Hitachi Group will not be able to bear any responsibility.

It is required for the customer side to clarify the target of the security protection of the system.

Then set up the typical measures as below, and build out and operate the system.

● Utilization and periodic review of the authentication function for the program and the data to be

protected

● Utilize the security functions of the device configuring the network

● Prevention of the unspecified connection by use of the function to identify the target

connection

● Measures in the operational management, such as to lock the location of devices or restrict

the operator

Please use the USB memory only on this device. Please do regularly virus check for the USB

by using a computer with the latest antiviruls software.

●Contents 1

1. USAGE PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Ink and makeup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 IJ printer long-term shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Print head cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 Shutdown (no-cleaning stop) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.5 Cautions on operating time when printer is in service . . . . . . . . . . . . . . . . 1-4

1.6 Heating of ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.7 Ink concentration control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.8 Gutter cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.9 Protection sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2. COMPONENT NAMES AND FUNCTIONS . . . . . . . . . . . . 2-1

2.1 External views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Main body internal parts arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3 Print head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

3. BASIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Start operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 Start operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.2 When an error occurred at the start of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.1.3 Ready and Standby state switching operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.1.4 Specifying the user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.2 Shut down operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.2.1 Automatically stopping by pressing one button (RX2-S only) . . . . . . . . . . . . . . . . . 3-13

3.2.2 Stopping ink ejection by pressing the screen button . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.2.3 Turning off the main power switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.3 Basic operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.3.1 Operating Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.3.2 Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3.3.3 Basic operation to change the settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3.3.4 Operations (OK, Back, Apply) which exit from a screen . . . . . . . . . . . . . . . . . . . . . 3-24

CONTENTS

2 ●Contents

4. CREATION AND PRINTING OF MESSAGES . . . . . . . . . .4-1

4.1 Print description screen (initial screen) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Edit messages to be printed (Change message screen) . . . . . . . . . . . . . . 4-3

4.3 Call and print saved messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.4 Overwrite messages to be printed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.5 Edit messages different from the current message . . . . . . . . . . . . . . . . . . 4-9

4.6 Save created messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.7 Set the print format (Fixed layout) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.7.1 Select the print items to be edited . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.7.2 Set the number of print lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4.7.3 Add and delete print items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.7.4 Set dot matrix, inter-character space, and other parameters . . . . . . . . . . . . . . . . . . 4-18

4.7.5 Print a bar code (RX2-S only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

4.8 Set the print format (Free layout; RX2-S only) . . . . . . . . . . . . . . . . . . . . . 4-24

4.8.1 Select the print items to be edited . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4.8.2 Set the print items to be edited. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

4.8.3 Add and delete print items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

4.8.4 Set dot matrix, inter-character space, and other parameters . . . . . . . . . . . . . . . . . . 4-30

4.8.5 Print a bar code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

4.8.6 Cautions for printing overlapped some print items . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

4.9 Print characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

4.9.1 Print fixed characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

4.10 Use the calendar function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

4.10.1 Print calendar characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

4.10.2 Print future date (offset) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

4.10.3 Print by substituting a different character for the date (substitution rule) . . . . . . . . 4-44

4.11 Print shift code (Optional on RX2-S). . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

4.12 Update the print contents at a fixed interval(Time count)

(Optional on RX2-S) . . . . . . . . . . . . . . . . . . . . . . 4-50

4.13 Use the count function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

4.13.1 Print count characters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

4.13.2 Use count multiplication printing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-65

4.13.3 Skip specified character and print (Count skip) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-68

4.14 Set the print specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-71

4.14.1 Set the character height, character width, and orientation . . . . . . . . . . . . . . . . . . . 4-71

4.14.2 Set repeat printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-80

4.14.3 Set various printing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-81

4.14.4 Fine adjust the print specifications (Adjust print parameters) . . . . . . . . . . . . . . . . . 4-83

4.15 Using the AI code input support function (RX2-S only) . . . . . . . . . . . . . 4-84

●Contents 3

3

5. MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Confirm the Unit information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2 Monitor operational status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3 Print without any sensor signal (Test print, Start printing). . . . . . . . . . . . . . 5-4

5.4 Confirm the registered software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.5 Checking the functions that can be performed . . . . . . . . . . . . . . . . . . . . . . 5-6

6. ENVIRONMENT SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 Set the user environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2 Set the date and time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.3 Set up the touch screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6.4 Changing the user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6.5 Setting password for each user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

7. AUXILIARY FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1 Manage messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.1.1 Managing stored messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.1.2 Changing the message name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.1.3 Deleting stored messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.1.4 Changing message number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

7.1.5 Changing the group to which a message belongs . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

7.1.6 Checking the print image of registered print data (RX2-S only) . . . . . . . . . . . . . . . . 7-10

7.2 Manage group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

7.2.1 Manage group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

7.2.2 Change group name. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7.2.3 Delete a stored group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

7.2.4 Change group number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

7.3 Creating a user pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

7.3.1 Creating and saving user pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

7.3.2 Selecting a user pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

7.3.3 Editing a pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

7.3.4 Creating a user pattern of a free size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

7.3.5 Selecting a bitmap file(BMP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

7.4 Touch screen coordinate correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

7.5 Backing up data to USB memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

7.5.1 Copy data all at once . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

7.5.2 Copy data individually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

7.6 Editing standard pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40

7.7 Editing Substitution Rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

7.8 Selecting Languages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-43

4 ●Contents

8. INK AND MAKEUP REPLENISHMENT. . . . . . . . . . . . . . .8-1

8.1 Replenishing the ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.2 Replenishing the makeup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

9. WHEN WARNING OR FAULT WAS GENERATED. . . . . . . . 9-1

9.1 Display when warning or fault was generated . . . . . . . . . . . . . . . . . . . . . . 9-1

9.2 On-screen message descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.2.1 Fault messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.2.2 Warning messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

9.2.3 Other messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

9.3 When checking the warning and fault generation status . . . . . . . . . . . . . 9-10

9.4 Remedial action to be taken in the event of a printing failure. . . . . . . . . . 9-11

10. TROUBLESHOOTING GUIDE. . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

11. EMERGENCY PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

12. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

13. APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

● Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

●Ink and makeup 1-1

Storage temperature Shutdown Period Guideline *1

0 to35 C 3 weeks

35 to 40 C 2 weeks

40 to 45 C 1 week

1.1 Ink and makeup

(1) Ink and makeup replenishment

The printer employs an automatic ink/makeup replenishment system. While the printer is operated, the

ink reservoir automatically supplies the ink and the makeup reservoir automatically supplies the makeup

to the ink main tank at regular intervals. If the ink or makeup replenisher level is too low, an alarm is

issued. In this case, replenish the ink or makeup without delay.

(For the replenishment procedures, see Section 8.)

(2) Ink periodic replacement

For the replacement procedures, see “Technical Manual Chapter 6”.

●While the IJ printer ink circulates for operations, it reacts with the atmospheric air elements and

deteriorates with time. Therefore, it needs periodic replacement. The guide for determining the

replacement interval conforms to the handling guidance of each ink.

*What is makeup? :

The makeup serves as the replenisher that makes up for the constituent loss due to ink

evaporation during ink ejection. It is also used as a cleaning solution.

1.2 IJ printer long-term shutdown

When the IJ printer is shut down for a long time due to production or other circumstances, the ink may

accrete inside of the printer and cause such problems as inability to be ejected or to be recovered. When

this occurs, the following actions must be taken.

Prevent accretion by operating the printer periodically.

Operate (eject ink) the printer for 1 hour or longer at least once during the “Shutdown Period

Guideline” shown in the table below.

Perform long-term shutdown storage work.

Before storage, drain the ink from inside the printer and fill the printer with makeup.

When restarting operation after storage, drain the makeup from inside the printer and fill the printer

with ink.

Refer to Technical manual “6.15 Long-term Shutdown” for detail.

*1: Maximum period the printer can be continuously shut down without being operated.

●The values in the table are for MEK based ink.

●Handling of ink other than the above requires special handling in accordance with the handling

guidance of each ink.

1. USAGE PRECAUTIONS

Since “ Perform long-term shutdown storage work” requires special work,

it is recommended to contact your local distributor and ask for the work.

CAUTION

1

2

2

1-2 ●Print head cleaning

1.3 Print head cleaning

Take the following precautions when cleaning ink from around the nozzle.

(1) Orient the end of the print head downward and pour makeup onto the dirty part and clean while

catching the makeup in a beaker.

(2) After cleaning, thoroughly wipe the print head with wiping paper and allow it to dry.

●Thoroughly dry the nozzle, charge electrode, deflection electrode, mounting base and fringe of the gutter.

Confirm that the parts are sufficiently dry before starting the next operation.

If operated while wet, the printer will not start normally.

●While the print head is wet, do not orient its end upward.

(3) Never immerse the print head in the makeup.

(4)When printing is frequently performed or the distance between the print material and the print head is short,

ink splashes may stain the end of the print head and the print head cover. If this condition is left unresolved, the

stained status will be made worse, resulting in a print error or emergency stop. If a print error or emergency

stop frequently occurs because of stain due to ink splashes, stop the operation in progress and clean the end of

the print head (around the nozzle, charge electrode, deflection electrode, mounting base and gutter) and the

print head cover. Do this in addition to the cleaning to be performed at the end of each day’s work.

Air purging of the print head is effective against staining due to ink splashing.

See the Technical Manual “3.1 Print head air purge”.

Cleaning range

Do not pour the makeup over this section.

Wipe the print head clean with wiping paper

dampened with the makeup.

Nozzle

Deflection electrode

Charge electrode

Gutter

●Shutdown 1-3

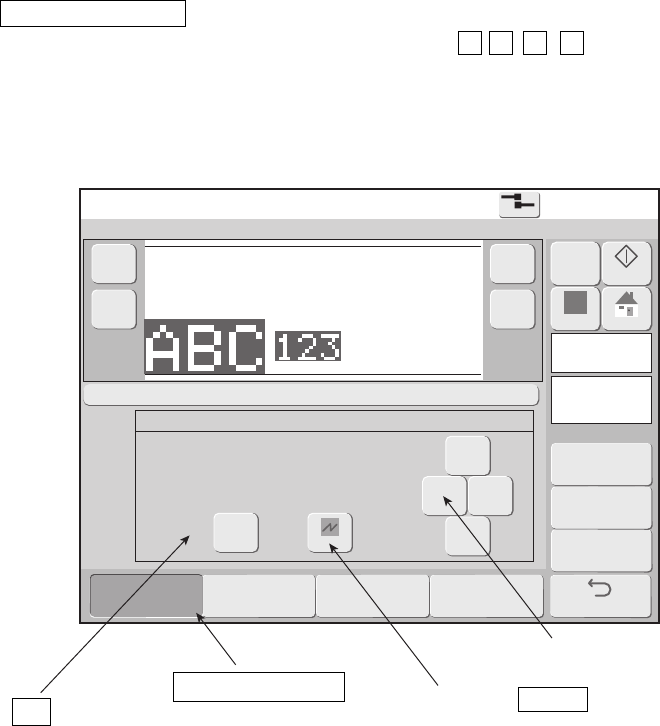

1.4 Shutdown (no-cleaning stop)

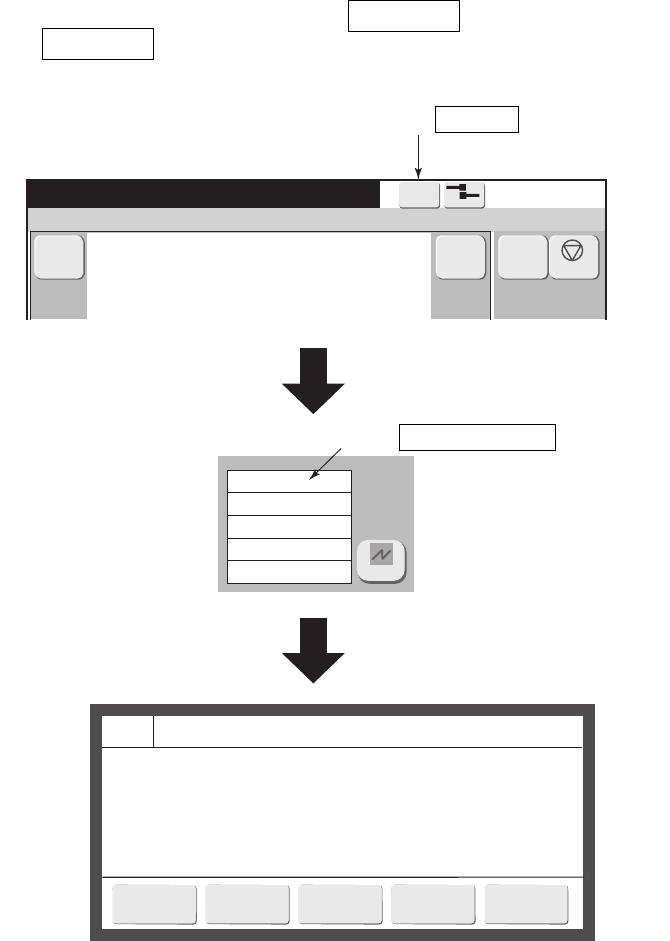

When you press the Shutdown on the upper right-hand corner of the screen, the printer stops after

completing its automatic nozzle cleaning sequence. If you repeatedly activate the Shutdown to stop an

operation, excessive makeup will enter the printer, thereby thinning the ink or producing an unduly high ink main

tank solution level. If it is absolutely necessary to repeatedly stop the printer operation, use the following

procedure.

Manual Control Menu

Start

printing

The current message is

printed.

No-cleaning

stop

Stops ink ejection

without cleaning.

Cancel

Standby

No deflection voltage is

applied. The printer

status becomes Standby.

Shutdown Process Confirmation

Shutdown will stop the ink jet.

Solution To stop the ink jet, press <OK>.

Press the Manual .

(The Manual is displayed commonly on all the screens.)

Press the No-cleaning stop within the control menu.

Press the OK .

An ink stop confirmation message appears.

*1: Do not use the Shutdown to stop operation more than two successive times.

*2: When operation was stopped using No-cleaning stop , if left in that state, the ink will become stuck in the

nozzle and cause ink stream bending, nozzle clogging, and printing disturbance. Apply makeup to the

orifice plate to wash it within 30 minutes after a stop to cause the ink to eject once again.

1

2

The no-cleaning stop procedure works even while the startup sequence is

being executed.

(The Shutdown button is inoperative during the startup sequence.)

2

3

Manual

Common to all screens

No-cleaning stop

1-4 ●Cautions on operating time when printer is in service

1.6 Heating of ink

(1) If the ambient temperature is under approximately 20 C, the ink is heated by a heating unit in the print head.

The startup processing time relative to when not operating becomes long.

When not operating: Approximately 1.5 minutes

When operating: Maximum approximately 10 minutes (Changes depending on the ambient temperature)

*Depending on the type of ink, the heating unit may not be used.

Refer to the handling guidance of each ink.

(2) When a heating unit fault occurs, take care of the following items.

If a heating unit fault occurs, the messages “Ink Heating Unit too High”, “Ink Heating Unit Temperature

Sensor Fault”, or “Ink Heating Unit Over Current” are displayed and the IJ printer fault stops.

The IJ printer can be restarted by pressing the Reset or Close . However, the ink will not be heated even

if the temperature drops thereafter.

Once “do not perform ink heating” is set, the following message is always displayed whenever the power

is turned on thereafter. Cancel the message by pressing the Close and be sure to inform your nearest

local distributor.

If the printer is temporally operated in "do not perform ink heating" status, the operation of the printer

may become possible by resetting the excitation voltage.

Reset the excitation voltage according to Technical Manual “6.11 Excitation V Adjustment”.

Ink Temperature Correction Notice

The selected setup does not allow ink temperature corrections

to be made.

Solution Contact your local distributor.

1.5 Cautions on operating time when printer is in service

(1) Cautions when printer is repeatedly stopped immediately after the start

of operation

If you repeatedly stop the printer immediately after the start of operation, automatic nozzle cleaning at shutdown

will cause the ink in the IJ printer to gradually become thinner. For stable operation of the IJ printer, operate the

printer for a given amount of time or more once started.( =in Ink eject status)

During the operation, the ink viscosity is adjusted automatically and returns to the initial value.

The required amount of operation time varies depending on the ambient temperature or ink types used.

Refer to the handling guidance of each ink for details.

(2) Caution when daily operating time is relatively long

The IJ printer emits an ink jet when printing, so the outside and inside of the print head cover will become dirty

with accumulated ink spillage during operation. To prevent printing defects due to this ink accumulation,

periodically check the head cover and clean it as required.

1

2

3

●Ink concentration control 1-5

No Ink Concentration Control

The current settings have made ink concentration control

unavailable.

Solution Contact your local distributor.

1.7 Ink concentration control

(1) The ink is automatically controlled to maintain optimum concentration for printing.

*Depending on the type of ink, ink concentration control may not be performed by viscometer.

Refer to the handling guidance of each ink.

(2)If an error occurs in the viscometer which is used to control ink concentration, take care of the following points:

There are three types of viscometer errors:

“Inside Temperature Sensor Fault”, “Viscometer Reading Instability”, and “Viscometer Reading Out of

Range”.

When a “Inside Temperature Sensor Fault” occurs, the unit will enter the fault stop state.

Re-start is possible by pressing the Close , but the setting will be changed to the state in which ink

concentration control based on the measured result using the viscometer is not performed thereafter.

Once the setting of automatic concentration control is released, every time the power is turned on, the

following message will appear. Cancel the message by pressing the Close and be sure to inform your

nearest local distributor.

When “Viscosity Reading Instability” or “Viscosity Readings Out of Range” occurs, the unit will not

enter the fault stop state and printing can be continued. However, you should contact your nearest

local distributor for inspection.

1

2

3

1.8 Gutter cleaning

The IJ printer collects ink not used for printing from the gutter. At the same time, it sucks in atmospheric gas, dust,

and other matter from the air. If these substances are mixed with the ink in the gutter, undissolved

components in the ink or makeup may stick to the gutter. If the system is run for 24 consecutive hours without

automatic cleaning, these components will gradually accumulate in the gutter. This, together with the ink stream

coming into contact with it, may cause such errors as “an error stemming from a dirty head”.

If any such component sticks to the gutter, immerse it in a solution of about 0.5% household dishwashing

detergent and clean it for about 10 minutes with an ultrasonic cleaner. The dirt can then be removed.

1-6 ●Protection sheet

1.9 Protection sheet

A protection sheet is provided to protect the screen display of the IJ printer.

This is used to prevent the screen display from becoming dirty, scratched, etc.

(1) Installing the protection sheet

Clean all dirt, debris, ink, etc., from the panel surface.

Use a paper wipe, etc., soaked in water or makeup to wipe the display clean.

*Install the protection sheet after the panel surface has dried.

Peel off the removable paper from the back of the protection sheet.

*Do not touch the double-sided tape on the back of the protection sheet.

Affix the protection sheet to the IJ printer screen display as shown in the figure.

1

2

3

Protection sheet parts No.:451902

(3pcs/pack)

(The protection sheet can be used

for both the RX2-S and RX2-B.)

(2) Usage Precautions

Be careful not to get ink or makeup on the protection sheet.

If ink or makeup does get on the protection sheet, wipe it off immediately.

When ordering the protection sheet,

please specify the following parts No.

●External views 2-1

2.

COMPONENT NAMES AND FUNCTIONS

2.1 External views

(1) External views

Operating status

indicator lamps

Displays "Ready",

"Fault" and

"Warning"

Handle

USB cover

Start / Stop switch

(*Standard Model only)

Main power switch

Power lamp

Maintenance cover

Opened/closed for ink

and makeup replacement

and other maintenance

purposes.

Print head

This section

performs printing.

2-2 ●Main body internal parts arrangement

(2) External views (rear side)

2.2 Main body internal parts arrangement

Air-purge

connection port

Makeup

reservoir

Ink reservoir

Maintenance

cover

Recovery filter

Pressure-reducing

valve

Ink filter

Main ink tank

Exhaust duct

connection port

Attention to the instruction of IJ printer

Stainless steel of the main body has the character it not to be easy rust, but it is

a possibility that rust is generated when leaving it for a long time. To prevent rust

being generated, we will recommend that the surface of the main body be kept

clean as much as possible.

●Print head 2-3

2.3 Print head

Print head cover lock thumbscrew

Nozzle orifice

Minus deflection electrode

Gutter

Plus deflection electrode

Charge electrode

3-1 ●Start operation

3.1 Start operation

3.1.1 Start operation

●The ink and makeup contains organic solvents.

When handling the ink and makeup, wear protective gloves and goggles so

that the ink will not directly contact your skin.

●An LCD touch panel is used for the screen.

Do not press the buttons with unreasonable force.

●If the system shuts down, turn off the main power switch.

To turn on the power and reuse the system, see “11. EMERGENCY

PROCEDURES”.

3. BASIC OPERATION

CAUTION

Turn on the power by pressing the main power switch.

1

Remove the print head cover, and check whether or not the print head cover and

the area around the nozzle are soiled by ink.

2

Since the IJ printer prints by ejecting ink against the print material, the outside and inside of the print

head cover are soiled by splashing of the ink from the print material. To prevent printing problems due

to soiling, check the soiling state and clean as required.

See “1.3 Print head cleaning” for a description of the cleaning method.

When stopped only by Stop switch and

the main power switch was not turned off

at the previous operation, the main power

switch does not have to be pressed

.

Loosen the screw.

Print head cover

Pull out.

Around nozzle

Operating status Indicator lamps

Stop switch

Start switch

Main power switch

●Start operation 3-2

3

Print description [Stop ]

Ink operating time (hours)

Cumulative op. time (hours)

Print count (prints)

Ink pressure (MPa standard value: )

Message name[ ] Current user ID : user2

●Confirm the print description, count value, and calendar character contents.

Press the Start switch. (Press for about 2 seconds.)

(Depending on the model, there may not be a Start switch. When the main power switch of 2 is

pressed, the following “Print description” screen appears.)

In the case of turning on the power again, ensure that status indicator lamp is off when Start switch is

pressed.

The “Print description” screen shown below appears.

If the “Select login user” screen opened, see “3.1.4 Specifying the user”.

3-3 ●Start operation

Ink Jet Startup Confirmation

The ink jet will be turned ON.

Solution To turn the ink jet ON, press <Ready>.

Place a piece of wiping paper, etc., against the ink injection port at the end of the print

head and press the Startup → Ready .

●Ink is ejected from the nozzle inside the print head.

●Place a piece of wiping paper, etc., against the ink ejection port in preparation for splashing of the ejected ink.

4

Print head

Wiping paper, etc.

Press Start up .

Press Ready .

●Start operation 3-4

● Continuous ejection of ink even though not printing is abnormal. If this occurs, press the Manual .

The Manual Control Menu appears. Stop ink ejection by pressing the No-cleaning stop → OK .

Manual Control Menu

Start

printing

The current message is

printed.

No-cleaning

stop

Stops ink ejection

without cleaning.

Cancel

Shutdown Process Confirmation

Shutdown will stop the ink jet.

Solution To stop the ink jet, press <OK>.

OK

Close

Standby

No deflection voltage is

applied. The printer

status becomes Standby.

● For a description of subsequent operation, see “3.1.2 When an error occurred at the start of operation”.

● At ink ejection, ink may momentarily spurt out and soil the paper. However, this is normal.

Wait until the status changes from “Starting” to “Ready”.

● When the temperature is low (approximately 20 C or lower), it may take longer than usual for the printer

to enter the “Ready” state.

5

Input the print target detection signal and check whether or not the print state and

print description are correct.

●If the print target detection signal is input when the status is “Ready”, the set print description is printed.

6

Press Manual .

Press No-cleaning stop .

Press OK .

3-5 ●Start operation

3.1.2 When an error occurred at the start of operation

Press the Manual . The Manual Control Menu appears. Stop ink ejection by

pressing the No-cleaning stop → OK .

1

Manual Control Menu

Start

printing

The current message is

printed.

No-cleaning

stop

Stops ink ejection

without cleaning.

Cancel

Shutdown Process Confirmation

Shutdown will stop the ink jet.

Solution To stop the ink jet, press <OK>.

OK

Close

Standby

No deflection voltage is

applied. The printer

status becomes Standby.

Press Manual .

Press No-cleaning stop .

Press OK .

●Start operation 3-6

* Thoroughly wipe off the makeup on the surface of each part (including the mounting base) and dry each part

thoroughly with wiping paper.

Clean the inside of the cleaning section with makeup.

Clean the orifice plate, charge electrode, deflection electrode, gutter, and mounting base with makeup.

(Also see “1.3 Print head cleaning”.)

3

Loosen the screw and remove the print head cover.

2

Orifice plate

Charge electrode

Deflection electrode

Mounting base

Beaker

Cleaning bottle

Gutter

Area to be cleaned

Loosen the screw.

Print head cover

Pull out.

Around nozzle

3-7 ●Start operation

Ink Jet Startup Confirmation

The ink jet will be turned ON.

Solution To turn the ink jet ON, press <Ready>.

With the print head cover removed, press the Startup → Ready .

● Ink is ejected from the nozzle. (The status changes from “Stop” to “Starting”.

● Operate the unit with the end of the print head remaining inside the beaker.

4

Press Start up .

Press Ready .

●Start operation 3-8

Confirm that the ink stream is at the center of the gutter.

● Check the position of the ink stream from the sides and top of the print head as shown in the figure

and confirm that it is in the center of the gutter.

5

● If the ink stream is not at the center of the gutter, perform step 1 and stop the ink injection. After

that, take action in accordance with Technical Manual “6.4 How to correct ink stream bending and

nozzle clogging”.

● Wear protective gear (goggles and mask) when checking the position of the ink stream.

● If you should get ink or makeup in your eyes or mouth, immediately wash with warm

water or water and see a doctor.

● When ejecting the ink, do it after confirming that there is no one in the ejection

direction.

(Operate with the end of the print head inserted in a beaker, etc.)

WARNING

Install the print head cover.

●Wait until the status changes to “Ready”.

●If the “Cover open” error was displayed, press the Close .

6

Input the print target detection signal and check the printing state.

(See “3.1.1 Start operation”.)

7

Gutter

Ink stream

Side direction

Upper direction

Gutter entrance diameter

The ink stream

should be positioned

at the center of the

gutter inlet.

3-9 ●Start operation

Manual Control Menu

Eject ink

Ejects ink while apply-

ing no deflection volt-

age.

Cancel

Ink Jet Startup Confirmation

The ink jet will be turned ON.

Solution To turn the ink jet ON, press <Ready>.

Ready

Cancel

Use this procedure when you want to eject ink from the nozzle for a purpose other than printing.

(Use only during maintenance. To print, use the Startup )

Press the Manual . The Manual Control menu appears. Press the Eject ink → Ready .

Ink ejection using the Manual Control Menu

● Operation can be aborted by pressing the Cancel at the “Manual Control Menu” and “Ink Jet

Startup Confirmation message”.

● If the print head cover installed, the printer will not enter the Ready state even if this operation is

performed. (Enters the Standby state)

Press Manual .

Press Eject ink .

Press Ready .

●Start operation 3-10

Manual Control Menu

Stops ink ejection

without cleaning.

Cancel

Print Abort Confirmation

Printing will be aborted.

Solution Press <OK> to abort.

OK

Cancel

No-cleaning

stop

No deflection voltage is

applied. The printer

status becomes Standby.

Standby

Start

printing

The current message is

printed.

3.1.3 Ready and Standby state switching operation

(1) “Ready” state → “Standby” state switching

● With the conveyor interlock being activated by “Ready” signal, should this “Ready” signal be

turned to “Standby”, the conveyor will stop.

Press the Manual . The Manual Control menu appears. Press the

Standby → OK .

1

Press Manual .

Press Standby .

Press OK .

3-11 ●Start operation

Manual Control Menu

Ready

The deflection voltage

is applied. The printer

status becomes Ready.

No-cleaning

stop

Stops ink ejection

without cleaning.

Cancel

Print confirmation

The current message data will be printed.

Solution Press <OK> to print.

OK

Cancel

(2) “Standby” state → “Ready” state switching

Press the Manual . The Manual Control Menu appears.

Press the Ready → OK .

1

Press OK .

Press Manual .

Press Ready .

●Start operation 3-12

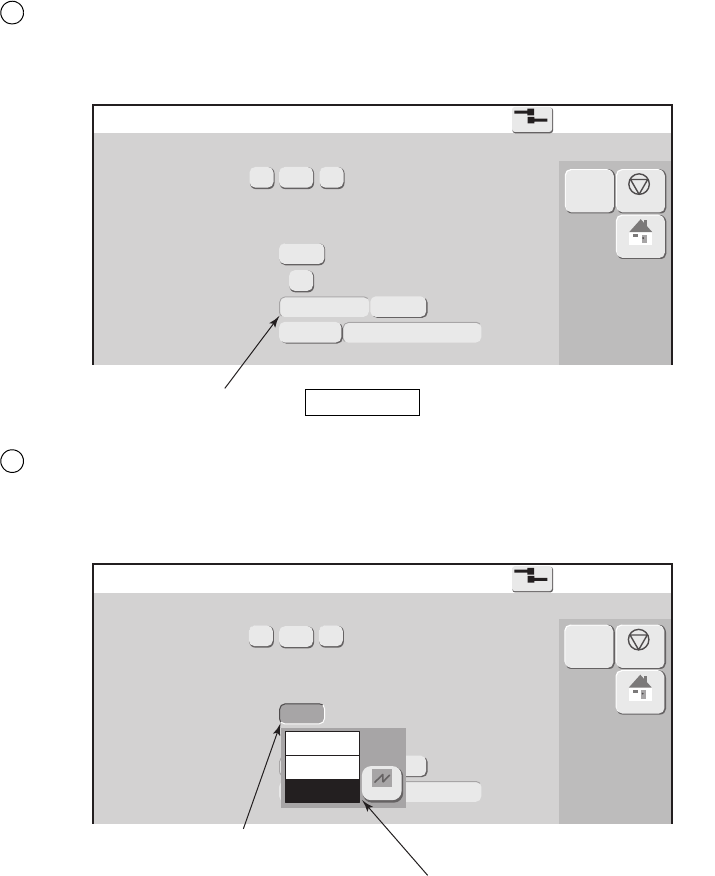

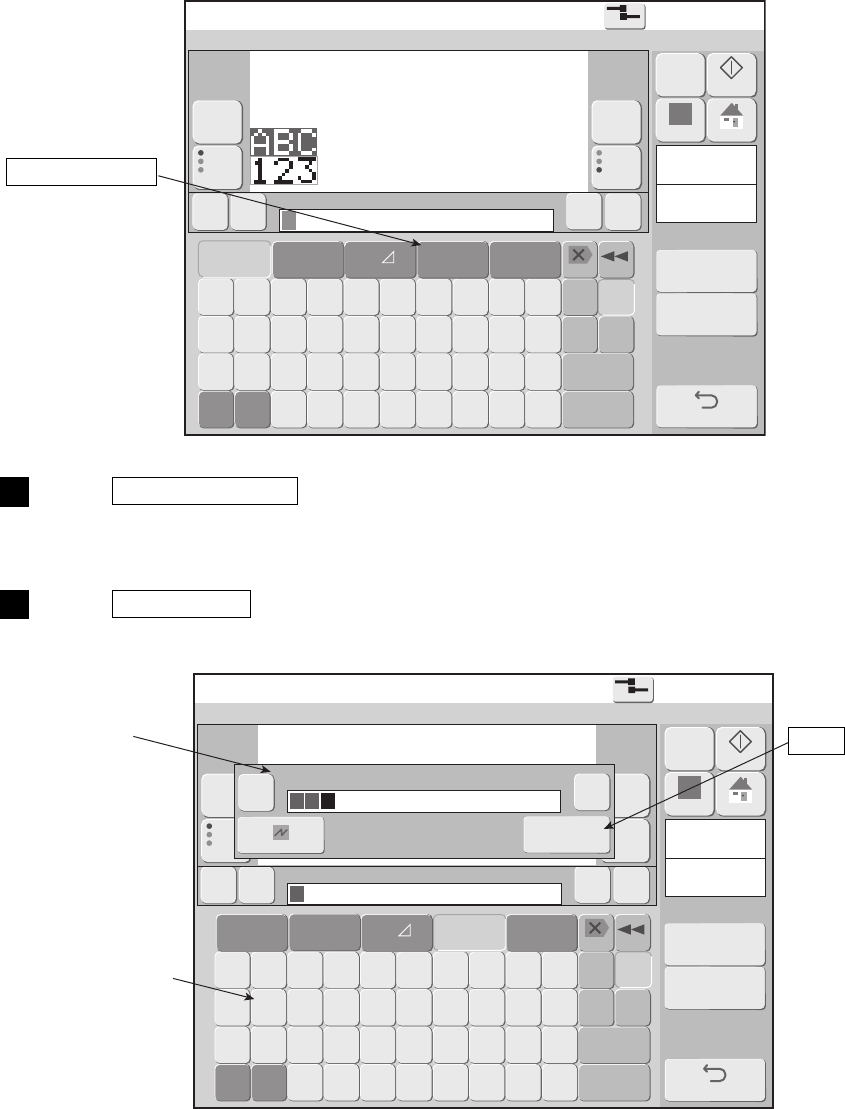

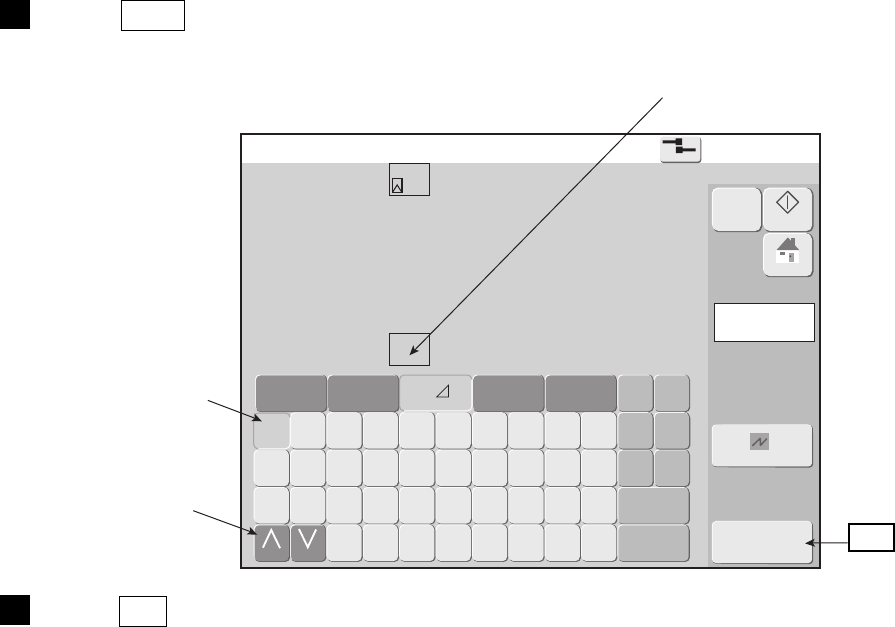

3.1.4 Specifying the user

(1) Functions

●Specifies the user to be logged in at power-on.

●Selects the user and inputs the password when logging in.

●The administrator defines the user name and password and password protection setting in advance.

The password protection setting can be changed beforehand for each user. The user name must be within

12 digits.

●Sets whether or not to select a user which logs in when the power is turned on.

See the Technical Manual “3.3 Selecting user when power is turned on”.

Select login user [Stop ]

Select login user [Stop ]

Turn on the power.

The Select login user screen is displayed.

1

Press user name user2 .

A password input window opens.

2

Input the password for user name “user2” and press Enter .

The initial screen is displayed.

3

The saved user

names are

displayed.

A password input

window opens.

Enter

(2) Operation

The administrator sets the login procedure necessary at power-on beforehand.

Please change the password periodically.

3-13 ●Shut down operation

3.2 Shut down operation

3.2.1 Automatically stopping by pressing one button

(RX2-S only)

Press the Stop switch. (Press for about 2 seconds.)

All operations up to IJ printer power OFF are performed automatically.

Depending on the model, there may not be a Stop switch. Stop the ink with the button on the screen

at 1 of par. 3.2.2, and turn off the power in accordance with par. 3.2.3.

1

The power is turned OFF by Stop switch from the state in which ink is being ejected or being stopped.

(The main power switch does not have to be turned off. The power consumption does not change even

if the main power switch remains ON.)

Main power switch

Start switch

Stop switch

●Shut down operation 3-14

3.2.2 Stopping ink ejection by pressing the screen button

● Perform ink stop processing using the following procedure.

Shutdown Process Confirmation

Shutdown will stop the ink jet.

Solution To stop the ink jet, press <OK>.

Press the Shutdown → OK .

A confirmation screen is displayed.

1

●Wait for the status to change from “Stopping” to “Stop”.

Press Shutdown .

Press OK .

3-15 ●Shut down operation

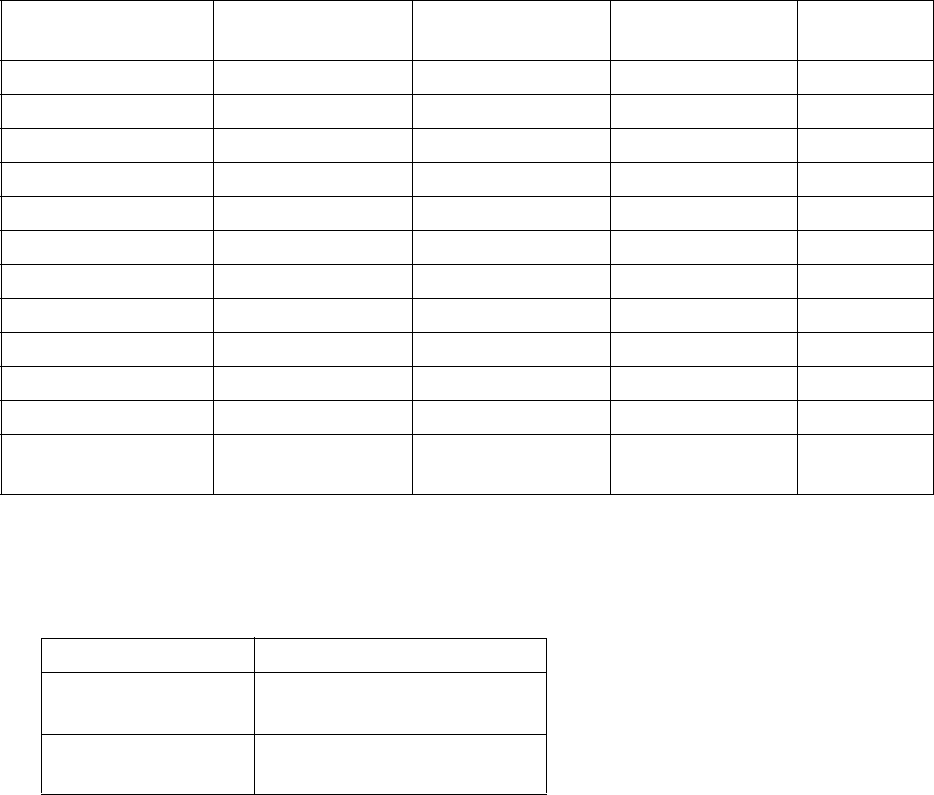

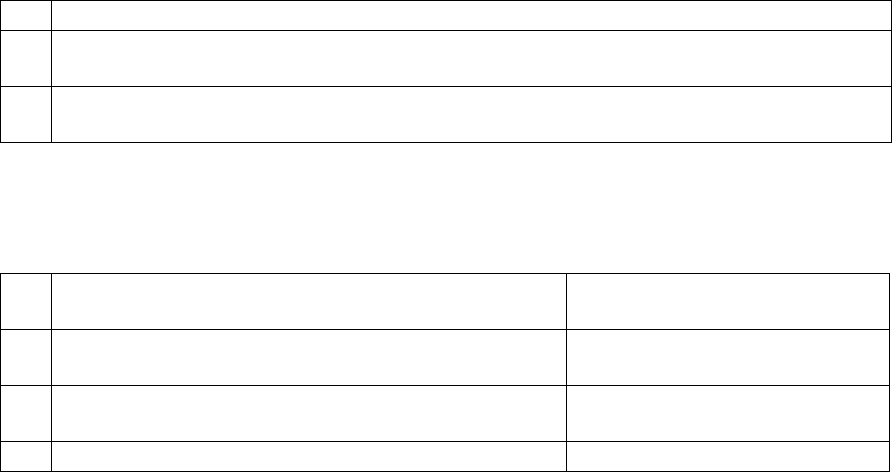

Turn off method Method which displays a screen at the next operation

When the main power switch was

turned off after being stopped by

Stop switch.

Screen is displayed when the startup switch is

turned ON after the main power switch was turned

ON.

When the main power switch was

turned off without using the stop

switch

Screen is displayed when the main power switch

is turned ON.

3.2.3 Turning off the main power switch

(1) RX2-S

●Press Stop switch normally instead of main power switch to turn off the power at the end of operation.

●If the IJ printer will not be used for a long time, turn off the main power switch.

●Do not turn off the main power switch while ink is being ejected.

See “11. EMERGENCY PROCEDURES”.

●The state when the power is turned on at the next operation differs depending on the state when the main

power switch was turned off.

(2) RX2-B

●Turn off main power switch at the end of operation.

●Do not turn off the main power switch while ink is being ejected.

●Shut down operation 3-16

1. The “nozzle rubber seal” prevents drying of the orifice plate and dust from sticking to the

plate. When the IJ printer will not be used for several days over a holiday, etc., we

recommend that the “nozzle rubber seal” be installed between the orifice plate and charge

electrode at shutdown.

Store the “nozzle rubber seal” in a plastic bag, etc., to protect it from dirt and dust.

Always install the “nozzle rubber seal” after cleaning it with makeup.

When installing the “nozzle rubber seal”, be careful not to deform the charge

electrode.

1

2

3

Usage precautions

Handling the nozzle rubber seal

Charge electrode

Orifice plate

Nozzle rubber seal

3-17 ●Basic operation

3.3 Basic operation

3.3.1 Operating Scheme

(1) Overall view

Print description

(Menu 1)

Print description

(Menu 2)

Power ON Power OFF

Operation

management

Select message

Over Write

message

Adjust print

parameters

Environment setup

menu

Auxiliary function

menu

Maintenance

menu

: Screen name

* See next page, Change message

Change message

Edit message

Print format

Print specifications

Change message

Adjust print

parameters

Edit message

Print format

Print specifications

Adjust print

parameters

Change message

Select

login user

Create/Edit

message

For print target data

For save data

Change message

●Basic operation 3-18

(2) Change message

Change message

Edit message

Print format

Print specifications

Various print

setup

Count conditions

Calendar

conditions

Adjust

Inter-character

space Substitution

rules

Shift code setup

(Op on RX2-S)

(Op on RX2-S)

Time count

conditions

* The display can be

switched between screens

Edit message,

Print format, and

Print specifications.

: Screen name

3-19 ●Basic operation

(3) Environment setup menu, Auxiliary menu, Maintenance menu

Environment setup

menu

Auxiliary function

menu

Maintenance

menu

User environment

setup

Date / time

setup

Communication

environment

setup

Touch screen

setup

Login

management

Manage

messages / Group

Create

user pattern

Calibration touch

screen coordinates

Copy data

(IJP → USB)

Copy data

(USB → IJP)

Edit standard

pattern

Edit substitution

rules

Select languages

Unit information

Operation

management

Tes t p rint

Excitation

V update

(Nozzle test)

View alarm

history

Circulation control

View software

version

Comm. monitor

(Optional on RX2-B)

Password

protection

Solenoid valve/

pump test

(Optional on RX2-B)

●Basic operation 3-20

Print description

Message name[ ]

[Ready ]

Current user ID : user2

Print description

Message name[ ]

[Stop ]

Current user ID : user2

Off line

Stop status

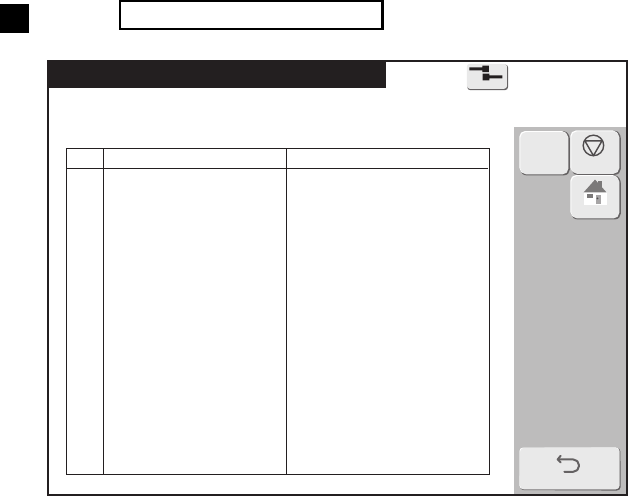

3.3.2 Status

(1) The printer is in one of the following states.

No. State Description

1 Stop The ink is stopped. No deflection voltage is applied.

2 Standby The ink is ejected. No deflection voltage is applied.

3Ready

The ink is ejected. The deflection voltage is applied (printing is permitted by the

sensor signal).

4 Starting State in which the printer changes from the inactive state to the standby state.

5 Ink heating Start up in process, with the ink being heated.

6 Stopping

State in which the printer changes from the standby state to the stop state.

7 Drop adjust Period during which ink particles are not properly charged in the standby state.

8 Cover open Period during which the nozzle head cover is open in the standby state

9 Service Circulation control process for maintenance task execution.

10 Fault State in which a fault exists.

(2) The current states including the on-line/off-line (communication) state is constantly displayed at the

top of the screen

.

Ready status

On line

3-21 ●Basic operation

Message name[ ]

[Ready ]Print description

Ink Low Warning

The ink level in the ink reservoir is low.

Cause 1. The ink reservoir is almost empty.

2. The Low Level sensor in the ink reservoir is faulty.

Solution 1. Add more ink to the ink reservoir within 60 minutes.

2. Check the Low Level sensor.

Ink Low Warning

Makeup Low Warning

Current user ID : user2

(3) When there is a “Not reset alarm”, a Warning is displayed.

When the Warning is pressed, a warning list is displayed.

Press Warning .

Warning list

Press Ink Low Warning .

●Basic operation 3-22

Excitation V-ref.

Ref. ambient temperature

Automatic update

Incremental change

Print trigger source

Print data

Inc.

Excitation V update [Standby ]

SensorButton input

Data to be displayed

For test

Incre-

ment

Enter

Clear

Decre-

ment

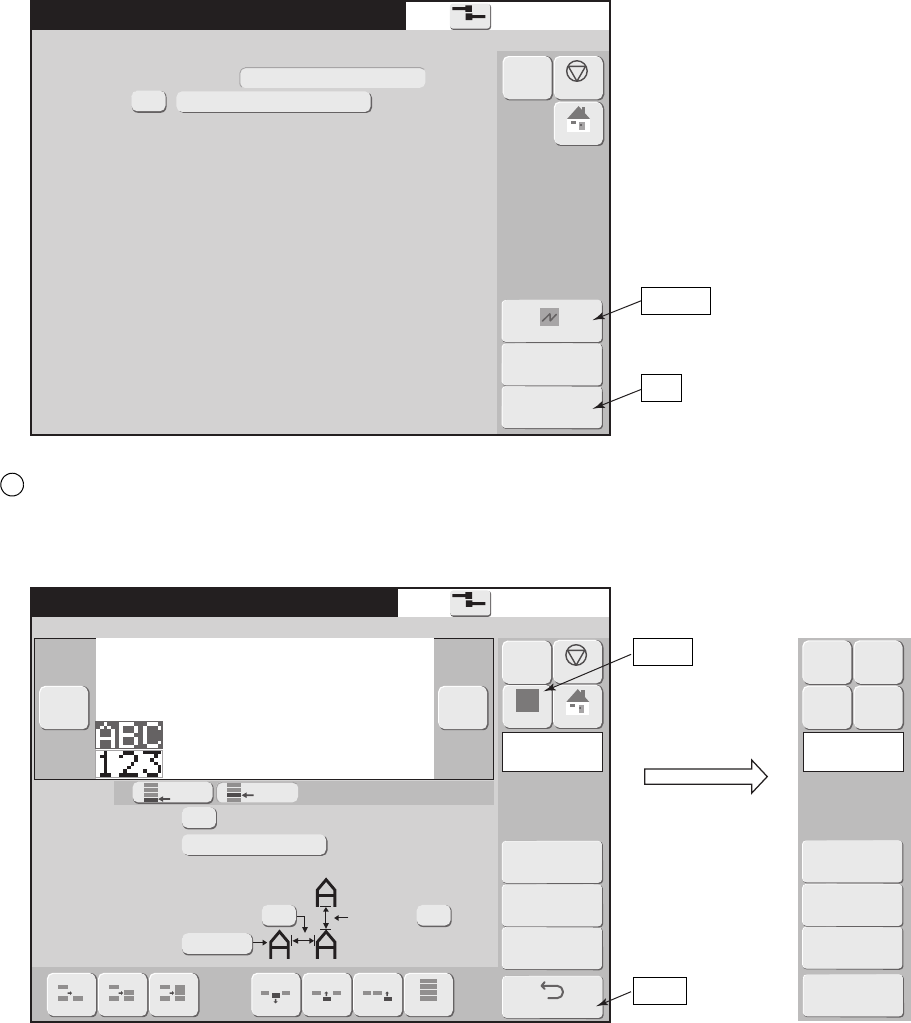

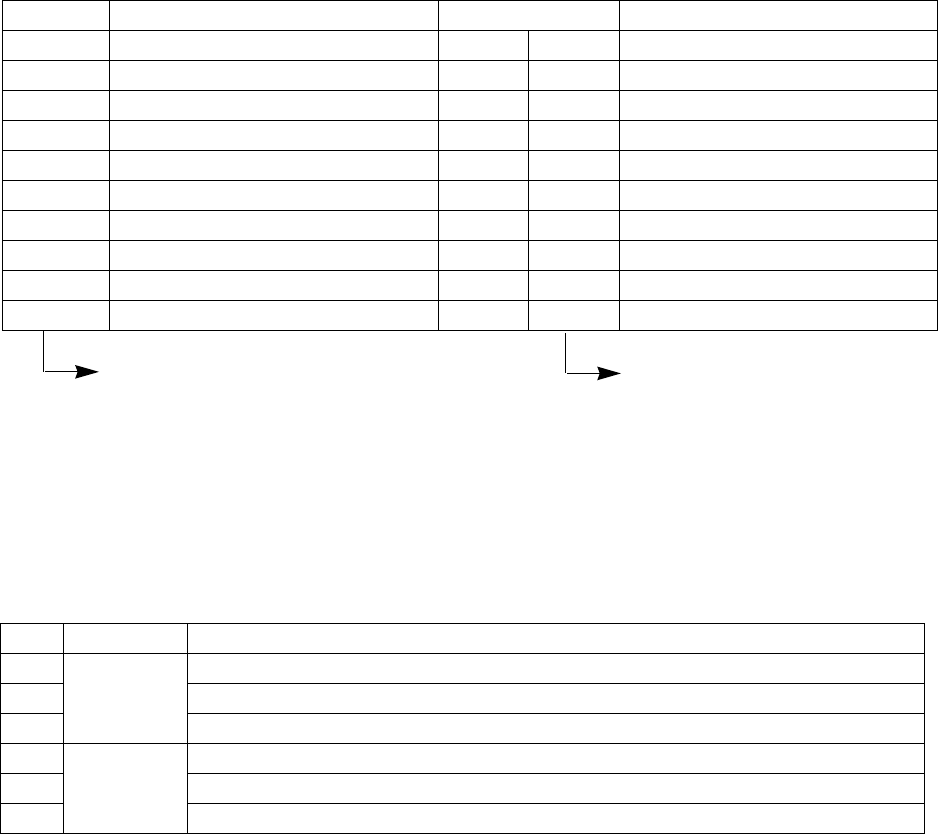

3.3.3 Basic operation to change the settings

(1) Overview

●There are 3 types of settings.

No. Classification

Set value confirmation

method

Set value change method

1 Setting of value

The value is displayed on

the numeric buttons.

Display the value window by

pressing the numeric button

and input the value.

2

Setting with few selections.

(All selection buttons are

displayed: mainly a choice

between the two)

The pressed button

becomes yellow.

Press the applicable button.

3

Settings with many selections.

(When a button is pressed, a

selection menu is displayed in a

window.)

The set value is displayed

on the input button.

Display the selection menu

window by pressing the but-

ton and select the

relevant item.

(2) Operation (Maintenance “Excitation V update” screen is used as an

example.)

●There are 3 types of settings.

1

“Excitation V-ref.” setting (Value input)

Display the numeric window by pressing the numbers button and input the value.

Minimum value is input.

Each time this button is

pressed, the set value is

increased by 1.

The value window is closed

and the input value is reflected

on the screen.

Each time this button is pressed,

the set value is decreased by 1.

Press the numeric button.

Numeric windows displayed.

Excitation V update [Standby ]

Excitation V-ref.

Ref. ambient temperature

Automatic update

Incremental change

Print trigger source

Print data

Inc.

SensorButton input

Data to be displayed

For test

3-23 ●Basic operation

2

Excitation V-ref.

Ref. ambient temperature

Automatic update

Incremental change

Print trigger source

Print data

Inc.

Data to be displayed

For test

Sensor

Button input

Excitation V update [Standby ]

Excitation V-ref.

Ref. ambient temperature

Automatic update

Incremental change

Print trigger source

Print data

Inc.

Data to be displayed

For test

Sensor

Button input

Disable

Dec.

Inc.

Excitation V update [Standby ]

“Print trigger source” setting

Press the applicable button.

3

“Automatic update” setting

Display the selection menu window by pressing the button and close from within that window.

Press the Button input .

Press the button.

Selection menu window is displayed.

●Basic operation 3-24

Date/time setup

Current time

Calendar time control

Calendar time

Clock system

24-hour clock

clock stop

(year)

(month) (day)

(hour) (minute) (second)

(year)

(month) (day)

(hour) (minute) (second)

12-hour clock

Press OK to apply the date/time setup.

The current time affects the clock display only

when changes are made.

Calendar character will be printed based on "calendar time"

same as current time

[Ready ]

No. Classification Contents

1

Screens with OK

and Cancel

● When OK is pressed, the set contents are accepted

and the display returns to the previous screen.

● When Cancel is pressed, the set contents are canceled

and the display returns to the previous screen.

● Apply is not displayed.

2 Screens with Back

● When Back is pressed, the display returns to the

previous screen.

● When Apply is pressed, the set contents are accepted.

● When Back was pressed in the state in which

Apply is not pressed, a confirmation window is displayed

and action is requested.

(2) Screen examples

Screen with OK and Cancel

[Example of Date/time setup screen]

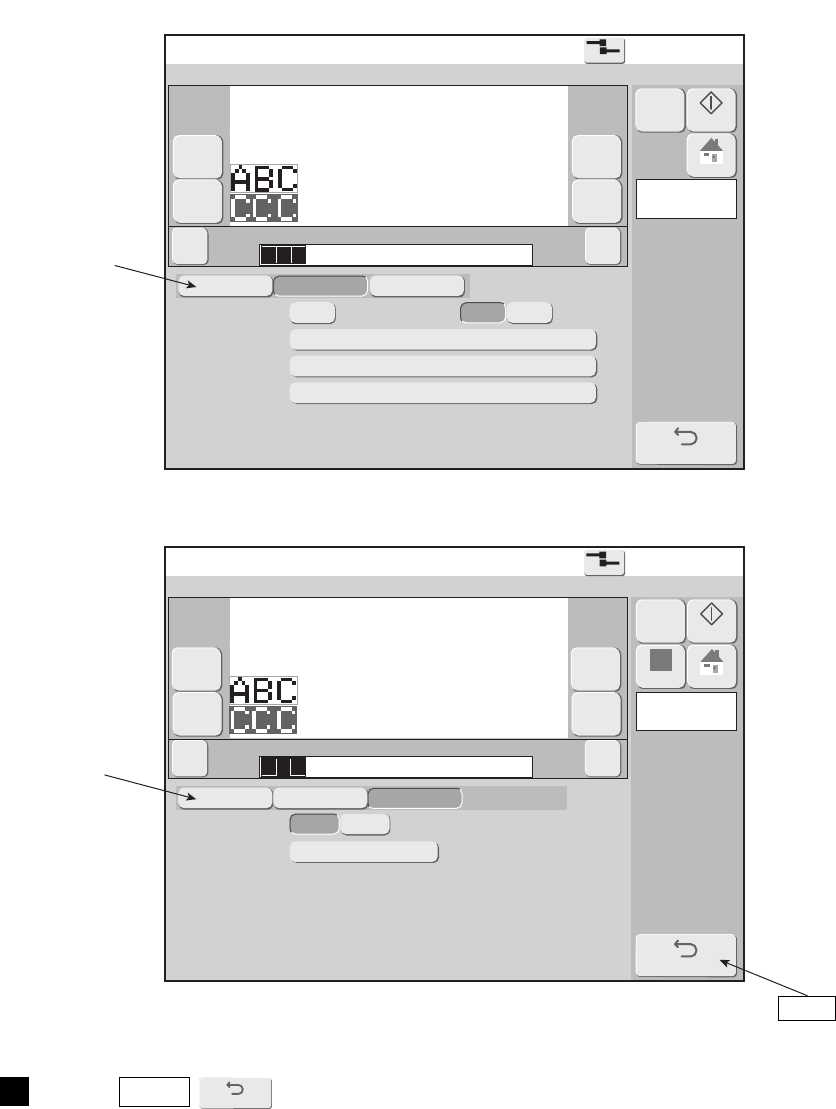

3.3.4 Operations (OK, Back, Apply) which exit from a screen

(1) Overview

●There are 2 types of setup screens.

● When “Apply” was performed during editing of the current message and at the User environment

setup screen, the set contents are reflected in printing.

● For the setup of whether or not to show some buttons as icon, refer to "6.3 setup the touch screen."

1

Cancel

OK

When set without

icons at the Touch

screen setup screen.

3-25 ●Basic operation

Save message [Ready ]

Message name [ ]

Save message as (name)

Group No.

Free space 20%

Print format [Ready ]

Select line

Bold times 1- 9

Bar code

Message name [ ]

Inter-char. space

(MAX 27 )

Line

spacing

(MAX 2 )

Dot matrix

[Example of Save message screen]

Screen with Back button

[Example of Print format screen]

2

Cancel

OK

Apply

Back

When set without

icons at the Touch

screen setup screen.

●Basic operation 3-26

Print format

Ready

Message name

Data Entry Confirmation

The data entered will be used in the print message.

Solution 1. To save the input data and use it for print message, press <OK>.

2. To delete the input data, press <Cancel changes>.

3. To return to the previous screen, press <Cancel>.

[Example of confirmation message when Back was pressed]

Accepts the

set contents.

Return from set

contents to original

contents.

Closes the message window with the

set contents remaining displayed.

4-1 ●Print description screen

4.

CREATION AND PRINTING OF MESSAGES

Print description [Stop ]

Ink operating time (hours)

Cumulative op. time (hours)

Print count (prints)

Ink pressure (MPa standard value: )

Message name[ ] Current user ID : user2

4.1 Print description screen (initial screen)

(1) Overview

● The display is shifted to the screens for message edit and Maintenance, Auxiliary function, and

Environment setup menu screens by pressing each button.

● The print image can be confirmed at the “Print layout” area.

Item Description Reference

Change message ● Edits and corrects current message. 4.2

Select message ● Calls and prints saved messages. 4.3

Overwrite message ● Overwrites the current message. 4.4

Adjust print parameters ● Creates and edits messages different from the current message. 4.14.4

Operation management ● Displays operation status. 5.2

Maintenance ● Displays the maintenance menu. 5

Auxiliary function ● Displays the auxiliary functions menu. 7

Environment setup menu ● Displays the environment setup menu 6

Select login user ● Logs in again as a different user from currently logged in user. 6.4

Create/Edit message ● Creates and edits messages different from the current message. 4.5

Print count reset ● Reset the print count to zero (0). 4.1

The Shutdown is displayed

during ink ejection.

The Startup is displayed

during stop.

Displays the

print layout.

Displays the operation

management

information.

When the Menu is pressed,

the display is switched.

Displays the zoom in

or zoom out.

Displays the scroll.

For details

regarding the

printing method

display, refer to

"4.14.1 Set the

character

height,

character width,

and

orientation."

Print count is

reset to 0.

If is indicated in

off-line state.

●Print description screen 4-2

Print description [Stop ]

Ink operating time (hours)

Cumulative op. time (hours)

Print count (prints)

Ink pressure (MPa standard value: )

Message name[ ] Current user ID : user2

(3) Current message and saved message

● There are 2 types of messages; current messages and saved messages.

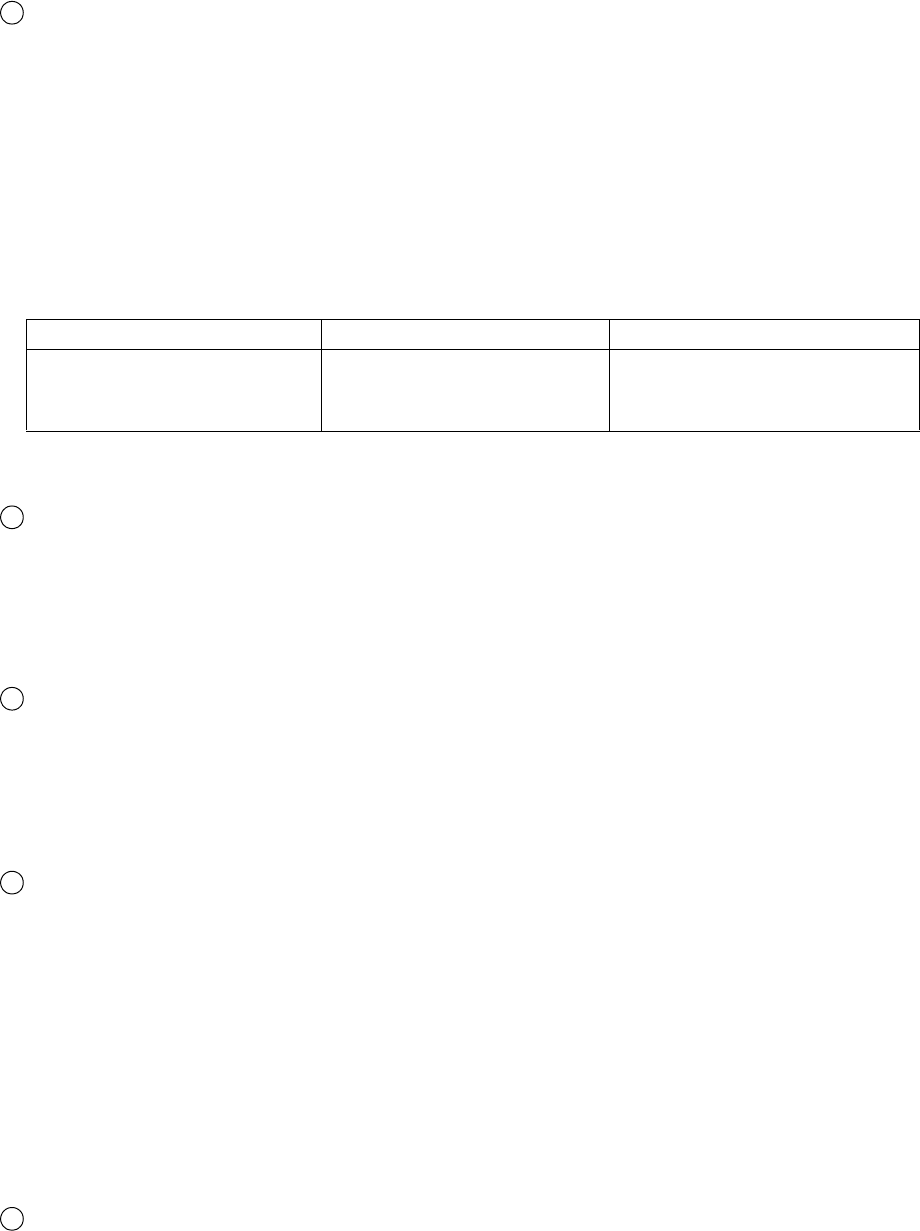

Types of messages

Type Features

Current message

● The message currently being printed is called “current message”.

● When the power is turned on, the last current message is memorized.

● The print layout of the current message is displayed on the Print description

screen.

● The contents of the current message can be changed by calling the message

from the saved messages.

Saved message

● Messages can be given a message name. Multiple messages can be saved

beforehand.

(2) Operation

The Print description screen is displayed.

Press the Print count reset on the Print description screen.

Confirmation message of "Print count reset." will be displayed.

1

Press OK on the confirmation message window.

Print count will be reset to zero (0).

2

Print count reset

4-3 ●Edit messages to be printed

4.2 Edit messages to be printed (Change message screen)

(1) Overview

● Edits the current message (message currently being printed).

● There are 2 types of print format.

● Style displayed in the Details mode of the message name list display of the Select message screen shows the

type of print format.

Types of Style

Type of Style Meaning Features

(a) Individual Individual setup of fixed layout Multiple character sizes can be mixed.

(b) Overall Overall setup of fixed layout

Character size and inter-character space set

value are matched at all lines.

Only 1 column can be input.

(c) Free layout Setup of free layout

An arbitrary position can be set for each print

item.

● The background of the current message edit screen is colored.

Edit screen background color

Editing objective Background color

Current message Light green

Saved message Gray

Print items are stacked

from the bottom.

Columns (vertical list) with the same

line count, line spacing, and character

size list are linked and handled.

Columns of several different

formats can be input.

(a) Individual setup

(b) Overall setup

Print items are stacked

from the bottom.

Only one column (vertical list) with the same line count,

line spacing, and character size list is handled.

(c)

Free layout

An arbitrary position can be

set for each print item.

A print item can be lapped over

other print items.

●Edit messages to be printed 4-4

●When the Apply is pressed during editing, the input value is applied and reflected in printing.

The input value is also applied when returning to the Print description screen by pressing the Back .

●When the Back is pressed at the Print format, Print specifications, and Edit message, various print setup

screens, the confirmation message "Data Entry Confirmation" is displayed.

Functions of confirmation message “Data Entry Confirmation”

Button Contents

OK Applies the message by input value and switches to the Print description screen.

Cancel changes Cancels the input value and returns to the state before the change.

Cancel Returns to the original screen with the input data as it was.

4-5 ●Edit messages to be printed

Print description [Stop ]

Ink operating time (hours)

Cumulative op. time (hours)

Print count (prints)

Ink pressure (MPa standard value: )

Message name[ ] Current user ID : user2

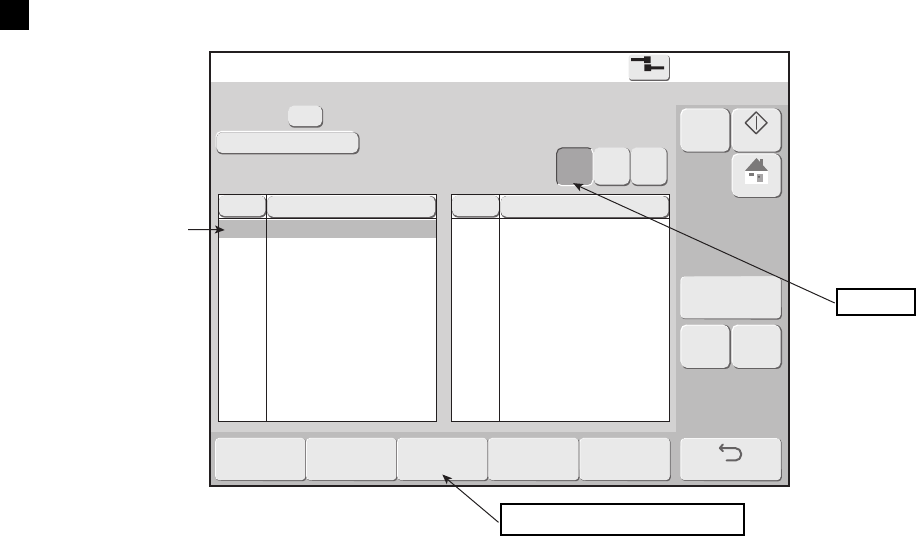

Change message [Stop ]

Message name[ ]

:Multiple print formats can be mixed.

<Format Setup>

:Character size and inter-character space set

value are matched at all lines.

Only 1 column can be input.

:An arbitrary position can be set for each print

item.

Change the display contents using the group, search, sort, and select page

functions so that the desired message name is displayed.

3

(2) Operation

The Print description screen is shown below.

Press the Change message on the Print description screen.

The Print format screen is displayed.

1

Press the Back .

To save as a registered print data ,press save and back .

4

Press Individual setup , Overall setup or Free layout to modify <Format

setup>.

2

Change message

●Call and print saved messages 4-6

4.3 Call and print saved messages

(1) Overview

● Calls and prints saved messages.

● The message currently being printed is called "Current message".

● When a message is called during printing, the Print description display changes to the called message and

printing continues to print the previous contents. The printed result changes from the next printing.

● The desired message can be efficiently found by changing the display contents of the message name list.

● A print image of the registered print data can be checked. (RX2-S only)

Method of changing the message name list display

Item Contents