PINTLE HOOKS

DRAWBARS

HOLLAND COUPLINGS

STRONG ROOTS AND A COMMON VISION:

ENGINEERING YOUR ROAD TO SUCCESS.

In 2006, two traditional companies merge to form SAF-

HOLLAND, and become one of the leading global suppliers

of high-quality axles and suspension systems, fifth wheels,

kingpins, coupling products and landing gear to the

commercial vehicles industry.

Alongside original equipment manufacturers (OEM) and

original equipment suppliers (OES), our customers also include

forwarding companies and service centres. Today, SAF-HOLLAND

is represented on all continents and distributes its products under

the brand names SAF and Holland through its own distribution

network and a global service and retailer network. In addition, we

also have our own research, development and test departments at

all our facilities.

With our components and systems, we are able to offer

first-class products and exemplary service – perfect problem

solutions for trucks, trailers and buses.

SAF-HOLLAND

NATIONWIDE n Melbourne

COVERAGE n Sydney

n Brisbane

n Perth

n Adelaide

WORLDWIDE n 40 branch offices

n 20 sales centres

n 3,838 service centres

17 production n Europe

locations overseas n North America

n Canada

n Brazil

n China

www.safholland.com.au

MOUNTING DIMENSIONS

162.3mm

221.7mm

171.5mm

41.4mm

50.8mm

2.00˝

or

50mm

BALL

137mm

11.7mm

114.3mm

44.5mm

86mm

13.5mm

APPLICATION:

A rigid mount pintle hook that combines a pintle hook

and ball hitch. Designed for customers who need the

strength and capacity to pull trailers equipped with

drawbars, as well as the flexibility to pull trailers with a

2” or 50mm ball hitch.

DRAWBAR EYE DIMENSIONS:

60.4mm to 76.2mm I.D. with 31.7mm to 41.4mm

diameter section.

NOTE : Specifications regarding measurements and

weights are nominal only. We reserve the right to make

changes as neccessary.

FASTLATCH- One-handed

operation and automatic

secondary lock

Forged from a

special alloy steel

body that is heat

treated for strength,

toughness, and

durability.

Our unique design is stronger and more durable

than a removable ball design. The special shape

eliminates premature wear typically caused by

the drawbar pulling against the ball. Provides

better oscillation or articulation in off-road

conditions than a removable ball hitch.

50mm ball is permanently

attached. It cannot be

stolen or misplaced.

BH50MMRN41

50mm (2”) DIAMETER BALL

RIGID MOUNT - DUPLEX

CAPACITY:

· 20 kN D-Value

· CRN 46665

· Weight 4.5 kg (10 lbs.)

· Pintle Hook:

1,800 kg (3,968 lbs.) Maximum Vertical Load

9,000 kg (19,842 lbs.) Maximum Gross Trailer Weight

· 50mm Ball:

4,540 kg (10,000 lbs.) Maximum Gross Trailer Weight

NOTE: For off-road applications, reduce the above

capacities by 25% and use with a swivel-

mount drawbar.

Tested in accordance with SAE J847 (Type II) and ADR

62/02.

Meets J684 Class 4 standard for a 50mm ball.

WARRANTY:

· 12 Months Materials and Workmanship Warranty

184.1mm

48.2mm

159.7mm

114.3mm

85.8mm

42.9mm

44.4mm

13.4mm DIA.

(4 HOLES)

APPLICATION:

A versatile rigid mount pintle hook designed for over-the

road and off-road towing within stated capacities.

DRAWBAR EYE DIMENSIONS:

50.8mm to 76.2mm I.D. with 31.7mm to 41.4mm

diameter section.

NOTE : Specifications regarding measurements and

weights are nominal only. We reserve the right to make

changes as neccessary.

PHT60AOL8

RIGID MOUNT

CAPACITY:

· 35 kN D-Value

· CRN 26465

· Weight 5 kg (11 lbs.)

· 2,724 kg (6,000 lbs.) Maximum Vertical Load

· 13,620 kg (30,000 lbs.) Maximum Gross Trailer

Weight

NOTE: For off-road applications, reduce the above

capacities by 25% and use with a swivel-

mount drawbar.

Tested in accordance with SAE J847 (Type II) and ADR

62/01.

WARRANTY:

· 12 Months Materials and Workmanship Warranty

Forged from a special alloy steel

that is heat treated for strength,

toughness, and durability.

A chain and

cotter pin are the

secondary lock.

Surfaces are machined to tight

tolerances to ensure durability.

The latch is forged

alloy steel and heat

treated for strength

and long life.

The special

pintle body

shape is

designed for

maximum

articulation or

oscillation and

reduced wear.

MOUNTING DIMENSIONS

REPLACEMENT PARTS

152.4mm

63.5mm

3mm

20.5mm DIA. TYP.

(6 REQ.)

76.2mm

152.4mm

95.2mm

47.7mm

82.5mm

DIA. MIN

184.1mm

146.3mm

24.6mm

266.7mm

152.4mm

96.5mm to 6mm

NPT Reducer

96.5mm

96.5mm NPT Plug

95.2mm

190.5mm

9.6mm MIN

50.8mm MAX

APPLICATION:

A rigid mount pintle hook designed for trailers,

semitrailers, and doubles operations. Used for off-

and over-the-road applications, with an air cushioned

snubber, designed to minimize the space between the

pintle hook and the drawbar and helps provide some

shock absorption. This pintle hook is recommended for

severe duty applications.

DRAWBAR EYE DIMENSIONS:

60.4mm to 76.2mm I.D. with 31.7mm to 41.4mm

diameter section.

NOTE : Specifications regarding measurements and

weights are nominal only. We reserve the right to make

changes as neccessary.

PH300 / PH3001

RIGID MOUNT

WITH AIR CUSHIONED SNUBBER

CAPACITY:

· 165 kN D-Value

· CRN 24295

· Weight 19 kg (42 lbs.)

The complete assembly includes a pintle body,

plunger, air chamber, and mounting bracket. For

pintle hooks without an air chamber, bracket, or

plunger, order PH3001. The PH300 can be operated

with or without the air chamber.

· 8,172 kg (18,000 lbs.) Maximum Vertical Load

· 32,688 kg (72,000 lbs.) Maximum Gross Trailer

Weight

NOTE: For off-road applications, reduce the above

capacities by 25% and use with a swivel-

mount drawbar.

Tested in accordance with SAE J847 (Type II) and ADR

62/01.

WARRANTY:

· 12 Months Materials and Workmanship Warranty

Automatic

secondary lock

for improved

safety.

Unique one-

handed latch

operation.

Body is wear

hardening austinetic

manganese material

for wear resistance.

Threaded

plunger is

adjustable.

Plunger/snubber force is

developed by the vehicle’s air

system to reduce wear and to

provide shock absorption.

Also available

without air

chamber and

mounting

bracket.

RK02536

XB02608 CYLINDER AND BRACKET SUB-ASSY.

XAT653 XE015441

INCLUDED

WITH

XAT653

INCLUDED

WITH

XAT653

XA04156

XA011551

RK02536

XB02608 CYLINDER AND BRACKET SUB-ASSY.

XAT653 XE015441

INCLUDED

WITH

XAT653

INCLUDED

WITH

XAT653

XA04156

XA011551

RK02536

XB02608 CYLINDER AND BRACKET SUB-ASSY.

XAT653 XE015441

INCLUDED

WITH

XAT653

INCLUDED

WITH

XAT653

XA04156

XA011551

XB02608

CYLINDER

AND

BRACKET

SUB-ASSY.

XA011551 RK02536

MOUNTING DIMENSIONS

CK22-02 Rev D 0408 Amendments and errors reserved. © SAF-HOLLAND (Aust.) Pty. Ltd.

APPLICATION:

Extreme duty construction, logging, milk hauling

primarily off-road applications provides torsional relief

where a significant amount of articulation is required in

a swivel-type mount pintle hook.

DRAWBAR EYE DIMENSIONS:

76.2mm I.D. with a 41.4mm diameter section.

NOTE : Specifications regarding measurements and

weights are nominal only. We reserve the right to make

changes as neccessary.

PH-775E-01552

LUBRICATED

CAPACITY:

· D = 180 kN

· Weight 27.2 kg (60 lbs.)

· 9,070 kg (20,000 lbs.) Maximum Vertical Load

· 45,360 kg (100,000 lbs.) Maximum Gross Trailer

Weight

NOTE: For off-road applications, reduce the above

capacities by 25% and use only with a non-

swivel mount drawbar.

WARRANTY:

· 12 Months Materials and Workmanship Warranty

· STANAG Compliant

A one piece housing

keeps contaminants

from entering the

pintle hook assembly.

Body and housing

are forged from

special alloy steel

and heat treated

for high strength,

toughness, and

wear resistance

for extreme duty

applications.

Cast alloy steel latch

is heat treated for

extreme strength

and durability.

Surfaces are machined

to tight tolerances to

ensure durability.

MOUNTING DIMENSIONS

Grease fitting for

easy lubrication.

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mmmm

mm

MOUNTING DIMENSIONS

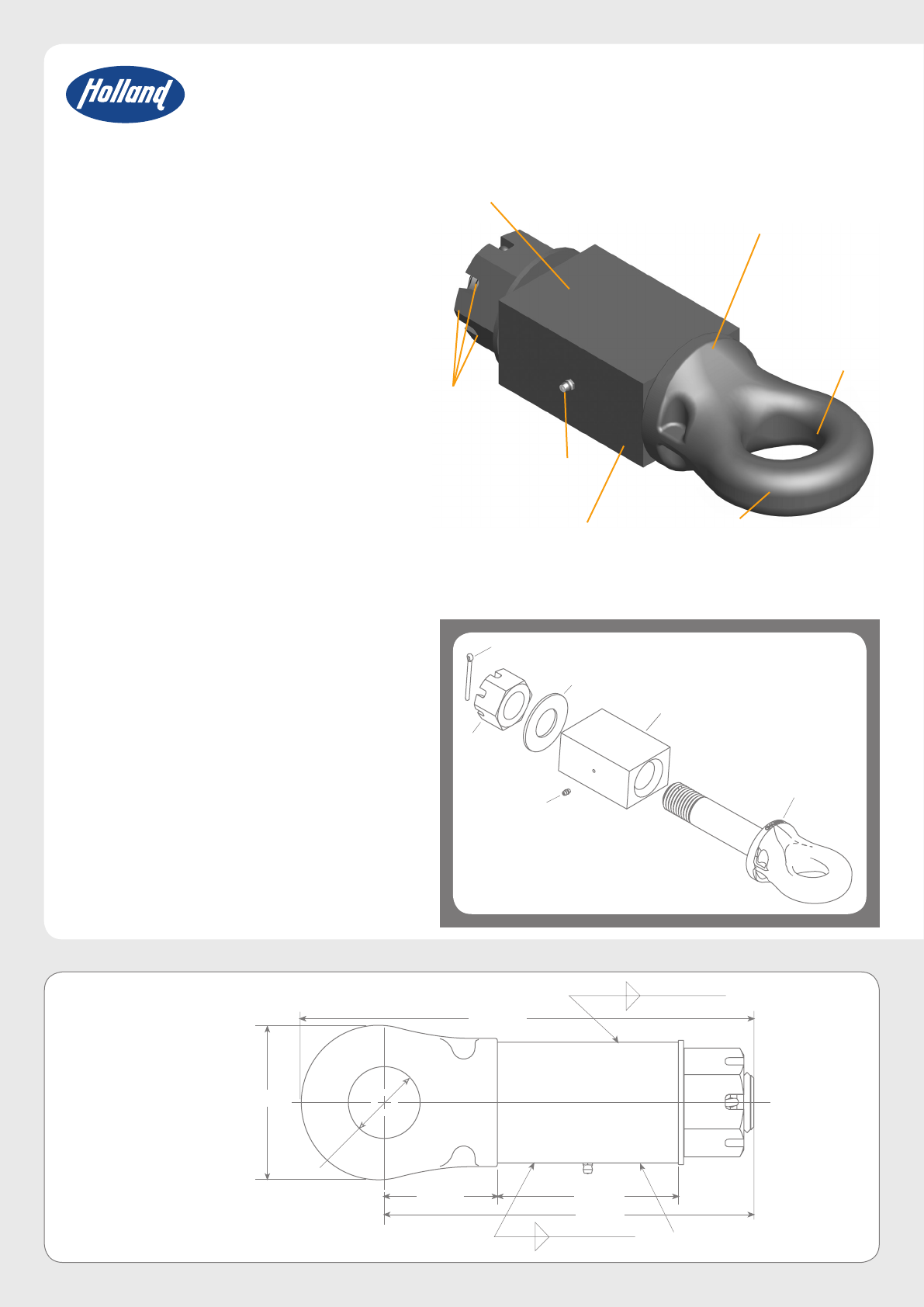

APPLICATION:

Used on trailers, semitrailers (including doubles), and

equipment designed for on- and off-road towing

applications within the stated capacities.

NOTE : Specifications regarding measurements and

weights are nominal only. We reserve the right to make

changes as neccessary.

DB-100FQ1

RIGID MOUNT – BOLT-ON

(4 BOLT MOUNTING BASE/PLATE MOUNT)

CAPACITY:

· D= 180kN

· Weight 8.6 kg (19lbs.)

· 9,079 kg (20,000 lbs.) Maximum Vertical Load

· 45,360 kg (100,000 lbs.) Maximum Gross Trailer

Weight

NOTE 1: Not designed to be welded to the trailer

tongue.

NOTE 2: For off-road applications, reduce the above

capacities by 25% and use with a swivel-

mount coupling device.

IMPORTANT: When used with hinged tongue trailers,

the maximum vertical load cannot exceed

227 kg (500 lbs.) and the maximum gross

trailer weight is 56,700 kg (125,000 lbs.).

WARRANTY:

· 12 Months Materials and Workmanship Warranty

The bolt head area

is strengthened

for more durability

than similar

products.

For maximum

durability and

minimum wear, the

drawbar eye has a

76.2mm I.D. with a

41.4 mm diameter

section to match a

pintle horn or coupler

jaw.

The bolt pattern is

the same as Holland

model DB-1250-15.

One piece forged alloy steel

drawbar is heat treated

throughout for greater strength,

durability, and toughness.

Ultra-light weight

with superior

strength!

162mm

173.4mm

18mm

94.2mm

41.4mm

DIA.

19.8mm DIA. THRU 4 HOLES

114.3mm

57.1mm

19mm

36.5mm

22mm

19.8mm

DIA.

162mm

57.1mm

114.3mm

18mm

162mm

173.4mm

18mm

94.2mm

41.4mm

DIA.

19.8mm DIA. THRU 4 HOLES

114.3mm

57.1mm

19mm

36.5mm

22mm

19.8mm

DIA.

162mm

57.1mm

114.3mm

18mm

APPLICATION:

Used on trailers, semitrailers (including doubles), and

equipment designed for on- and off-road towing

applications within the stated capacities.

NOTE : Specifications regarding measurements and

weights are nominal only. We reserve the right to make

changes as neccessary.

DB1385

RIGID MOUNT – BOLT-ON

(4 BOLT MOUNTING BASE/PLATE MOUNT)

CAPACITY:

· 165 kN D-Value

· CRN 24296

· Weight 8.6 kg (19 lbs.)

· 6,310kg (15,000 lbs.) Maximum Vertical Load

· 27,240kg (60,000 lbs.) Maximum Gross Trailer

Weight

NOTE 1: Not designed to be welded to the trailer

tongue.

NOTE 2: For off-road applications, reduce the above

capacities by 25% and use with a swivel-

mount coupling device.

IMPORTANT: When used with hinged tongue trailers,

where the maximum vertical load cannot

exceed 227kg (500 lbs), the maximum

gross trailer weight is 40,860kg

(90,000 lbs.).

Tested in accordance with SAE J847 (Type II) and ADR

62/01.

WARRANTY:

· 12 Months Materials and Workmanship Warranty

The bolt pattern is the

same as the previous

DB1385 model but

now uses 20mm bolts.

The bolt head area

is strengthened for

greater strength and

durability than similar

products.

The drawbar

eye is 76.2mm

I.D. with a

41.4mm diameter

cross section.

It is induction

hardened in

the pintle hook

contact area

for increased

strength and

wear resistance.

One piece forged alloy steel drawbar

is heat treated throughout for greater

strength, durability, and toughness.

MOUNTING DIMENSIONS

Weighs less

than the

competition.

152.4mm

155.7mm

16mm

85.8mm

31.7mm x

38.1mm DIA.

16.6mm DIA.

THRU 4 HOLES

114.3mm

57.1mm

41.4mm

57.1mm

114.3mm

63.5mm DIA.

16mm

31.7mm x

38.1mm DIA.

152.4mm

152.4mm

155.7mm

16mm

85.8mm

31.7mm x

38.1mm DIA.

16.6mm DIA.

THRU 4 HOLES

114.3mm

57.1mm

41.4mm

57.1mm

114.3mm

63.5mm DIA.

16mm

31.7mm x

38.1mm DIA.

152.4mm

MOUNTING DIMENSIONS

APPLICATION:

Used on trailers, semitrailers (including doubles), and

equipment designed for on- and off-road towing

applications within the stated capacities.

NOTE : Specifications regarding measurements and

weights are nominal only. We reserve the right to make

changes as neccessary.

DB040DQ1 (REPLACES DB125015)

RIGID MOUNT – BOLT-ON

(4 BOLT MOUNTING BASE/PLATE MOUNT)

CAPACITY:

· Weight 6.3 kg (14 lbs.)

· 3,632 kg (8,000 lbs.) Maximum Vertical Load

· 18,160 kg (40,000 lbs.) Maximum Gross Trailer

Weight

NOTE 1: Not designed to be welded to the trailer

tongue.

NOTE 2: For off-road applications, reduce the above

capacities by 25% and use with a swivel-

mount coupling device.

IMPORTANT: When used with hinged tongue trailers,

the maximum vertical load cannot exceed

227 kg (500 lbs.) and the maximum gross

trailer weight is 27,240 kg (60,000 lbs.).

Tested in accordance with SAE J847 (Type II).

WARRANTY:

· 12 Months Materials and Workmanship Warranty

The bolt head area

is strengthened

for more durability

than similar

products.

For maximum

durability and

minimum wear, the

drawbar eye has a

63.5mm I.D. with a

31.75mm x 38.1mm

diameter section to

match a pintle horn

or coupler jaw.

The bolt pattern is

the same as Holland

model DB-1250-15.

One piece forged alloy steel

drawbar is heat treated

throughout for greater strength,

durability, and toughness.

Ultra-light weight

with superior

strength!

MOUNTING DIMENSIONS

*See note

9.6mm

381mm REF

76.2mm (DEPTH)

152.4mm

311.1mm

*See note

9.6mm

95.2mm

60.4mm

130mm

HOLLAND

APPLICATION:

Used on straight tongue trailers, semitrailers (including

doubles), and equipment designed for on- and off-road

towing applications within the stated capacities.

NOTE : Specifications regarding measurements and

weights are nominal only. We reserve the right to make

changes as neccessary.

DB045BW1

SWIVEL MOUNT WELD-ON

CAPACITY:

· D-Value TBA

· CRN TBA

· Weight 17.3 kg (38 lbs.)

· 4,086 kg (9,000 lbs.) Maximum Vertical Load

· 20,430 kg (45,000 lbs.) Maximum Gross Trailer

Weight

NOTE 1: This drawbar must be used only in conjunction

with a rigid mount coupling device.

NOTE 2: For off-road applications, reduce the above

capacities by 25%.

IMPORTANT: When used with hinged tongue trailers,

where the maximum vertical load cannot

exceed 227 kg (500 lbs,) the maximum

gross trailer weight is 38,590 kg

(85,000 lbs.).

WARRANTY:

· 12 Months Materials and Workmanship Warranty

REPLACEMENT PARTS

XB121

XBT318

XA61023

XA05833A

XB767

XBT316A

The shank mount

is easy to replace

and offers compact

installation.

Drawbar

includes a

washer, nut,

cotter pin, and the

assembly includes a zerk

fitting for easy lubrication.

Steel fabricated housing.

Surfaces are machined to

tight tolerances to provide

durability and long life.

50mm O.D.

shank.

Forged alloy steel and heat

treated throughout for

toughness, strength, and

durable operation.

The drawbar

eye is 60.4mm

I.D. with a

41.4mm

diameter cross

section.

The drawbar eye is induction

hardened in the pintle hook

contact area for increased wear

resistance and durable service.

*NOTE: 24 linear inches

of 9.6mm fillet

weld are required

to develop hitch

strength.

APPLICATION:

Used on dog trailers, dollies, and equipment designed

for on- and off-road towing applications within the

stated capacities.

NOTE : Specifications regarding measurements and

weights are nominal only. We reserve the right to make

changes as neccessary.

DB61030S/

DB61030

SWIVEL MOUNT / WELD-ON

CAPACITY:

· D= 150kN (ADR 62/02)

· CRN 42325

· Weight 16.3kg

· 4,086 kg (9,000 lbs.) Maximum Vertical Load

· 20,412 kg (45,000 lbs.) Maximum Gross Trailer

Weight

· Length 434.9mm

NOTE 1: This drawbar must be used only in conjunction

with a rigid mount coupling device.

NOTE 2: This drawbar can be used for on-road

applications with hinged drawbars only.

NOTE 3: For off-road applications, reduce the above

capacities by 25%.

IMPORTANT: When used with hinged tongue trailers,

where the maximum vertical load cannot exceed 227

kg (500 lbs,) the maximum gross trailer weight is

38,500 kg (85,000 lbs.).

WARRANTY:

· 12 Months Materials and Workmanship Warranty

REPLACEMENT PARTS

XA-1249-49-10

XB-121

XB-T-316-A

XB-T-318

The shank mount

is easy to replace

and offers compact

installation.

Drawbar

includes a

washer, nut,

cotter pin, and the

assembly includes a zerk

fitting for easy lubrication.

Steel fabricated housing.

Surfaces are machined to

tight tolerances to provide

durability and long life.

50mm O.D.

shank.

The drawbar eye is induction

hardened in the pintle hook

contact area for increased wear

resistance and durable service.

434.9mm

76.2mm

DIA.

139.7mm

152.4mm

0.38x45º

355.6mm

51.6mm

158.75mm

DIA.

41.4mm DIA.

SECTION

NOTE: The mounting surface must have an adequate

chamfer, as shown above, so that the drawbar

mounts ush with the mounting surface.

*NOTE: 24 linear inches

of 9.6mm fillet

weld are required

to develop hitch

strength.

SAF-HOLLAND (Aust.) Pty. Ltd. · PO Box 63 · 115 High St · Melton Vic 3337

Tel: (03) 9971 7900 Fax: (03) 9743 6763

Western Australia · Tel: (08) 9353 1720 Fax: (08) 9353 1730

Queensland · Tel: (07) 3375 7033 Fax: (07) 3375 7044

New South Wales · Tel: (02) 9672 1950 Fax: (02) 9672 1994

South Australia · Tel: (08) 8346 7035 Fax: (08) 8346 3583

CK22-02 Rev F 0914 Amendments and errors reserved. © SAF-HOLLAND (Aust.) Pty. Ltd.

HIGH QUALITY COMPONENTS FOR THE COMMERCIAL VEHICLE INDUSTRY

EUROPE · NORTH AMERICA · SOUTH AMERICA · AFRICA · ASIA · AUSTRALIA

AXLES &

SUSPENSION

SYSTEMS

LANDING GEAR KINGPINS FIFTH WHEELS COUPLING

PRODUCTS

SAF ‘s history begins in 1881 in a village forge in Germany with the invention of a new plough.

The family business soon starts building steel axles for agricultural vehicles, and under the name

Otto Sauer Achsenfabrik (SAF) develops into one of the leading manufacturers of trailer axles

and suspension systems in Europe.

A safety coupling between plough and horse team can be found at the beginning of Holland‘s

history. The Safety Release Clevis Company was founded in South Dakota, USA , in 1910. After

its move to Holland, Michigan, the company emerges as one of the largest supplier companies

to the commercial vehicles industry under the name The Holland Hitch Company.

The merger of the two companies to form SAF-HOLLAND in 2006 creates one of the leading

global suppliers of high-quality components and services for the commercial vehicle industry.

Alongside axle and suspension systems for trailers and semi-trailers, the product range also

includes kingpins and landing gear as well as fifth wheels for tractors, air suspensions, coupling

products and numerous other components for buses and trucks.

Today SAF-HOLLAND is represented on all continents and distributes its products and services

worldwide under the brand names SAF and HOLLAND. It can boast of an extensive distribution

network with global service and dealer locations.

w w w . s a f h o l l a n d . c o m . a u